6

REFER TO FIG. 1 FOR CONNECTION DETAILS. BEFORE

ATTACHING THE GAS LINE BE SURE THAT ALL GAS PIPE IS

CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG)

MUST BE INCORPORATED IN THE PIPING, FIG. 1. The dirt leg

must be readily accessible. Install in accordance with

recommendations of serving gas supplier. Refer to the latest

edition of ANSI Z223.1.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to thermostat gas inlet.

The thermostat inlet has a pad for use with a backup wrench.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases. Do not use teflon tape on thermostat fittings.

CONNECTION OF GAS PIPE

1. When connecting gas pipe to unit, apply wrench to flange

only. Note: Do not use wrench on gas valve or gas valve

bracket.

2. PERFORM THE GAS LEAK TEST ANY TIME WORK IS DONE

ON A GAS SYSTEM TO AVOID THE POSSIBILITY OF FIRE OR

EXPLOSION WITH PROPERTY DAMAGE, PERSONAL

INJURY, OR LOSS OF LIFE.

The Gas Leak Test is performed as follows: Paint pipe

connections upstream of gas control with a rich soap and

water solution to test for leaks before operating main burner.

Bubbles indicate gas leak. To stop leak, tighten pipe

connections. After piping connections are checked, turn on

main burner. (See Lighting and Operating Installations in

this manual or on water heater.) With main burner in operation,

paint pipe joints (including flanges), pilot gas tubing

connections and control inlet and outlet with rich soap and

water solution. Bubbles indicate gas leak. To stop leak,

tighten flange screws, joints and pipe connections. Replace

part if leak can't be stopped.

DISCONNECT THE APPLIANCE AND ITS INDIVIDUAL SHUT

OFF VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING

ANY SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSI (3.5

kPa). GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES AT 1/2 PSI (3.5 kPa) OR LESS, THE APPLIANCE

NEED NOT BE DISCONNECTED, BUT MUST BE ISOLATED

FROM THE SUPPLY PRESSURE TEST BY CLOSING THE MAIN

MANUAL GAS VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR OTHER

MATERIAL ACCEPTABLE FOR THIS PURPOSE. DO NOT USE

MATCHES CANDLES, FLAME OR OTHER SOURCES OF

IGNITION TO LOCATE GAS LEAKS.

RELIEF VALVE

A NEW TEMPERATURE AND PRESSURE RELIEF VALVE

COMPLYING WITH THE STANDARD FOR RELIEF VALVES AND

AUTOMATIC GAS SHUT OFF DEVICES FOR HOT WATER

SUPPLY SYSTEMS, ANSI Z21.22 (LATEST EDITION) MUST BE

INSTALLED IN THE HEATER IN THE MARKED OPENING

PROVIDED. THE VALVE MUST BE OF A SIZE (INPUT RATING)

THAT WILL BE ADEQUATE FOR YOUR SIZE HEATER.

Check the metal tag on the relief valve and compare it to the

heater’s rating plate. The pressure rating of relief valve must not

exceed the working pressure shown on the rating plate of the

heater. In addition the hourly Btu rated temperature steam

discharge capacity of the relief valve shall not be less than the

input rating of the heater. NO VALVE IS TO BE PLACED

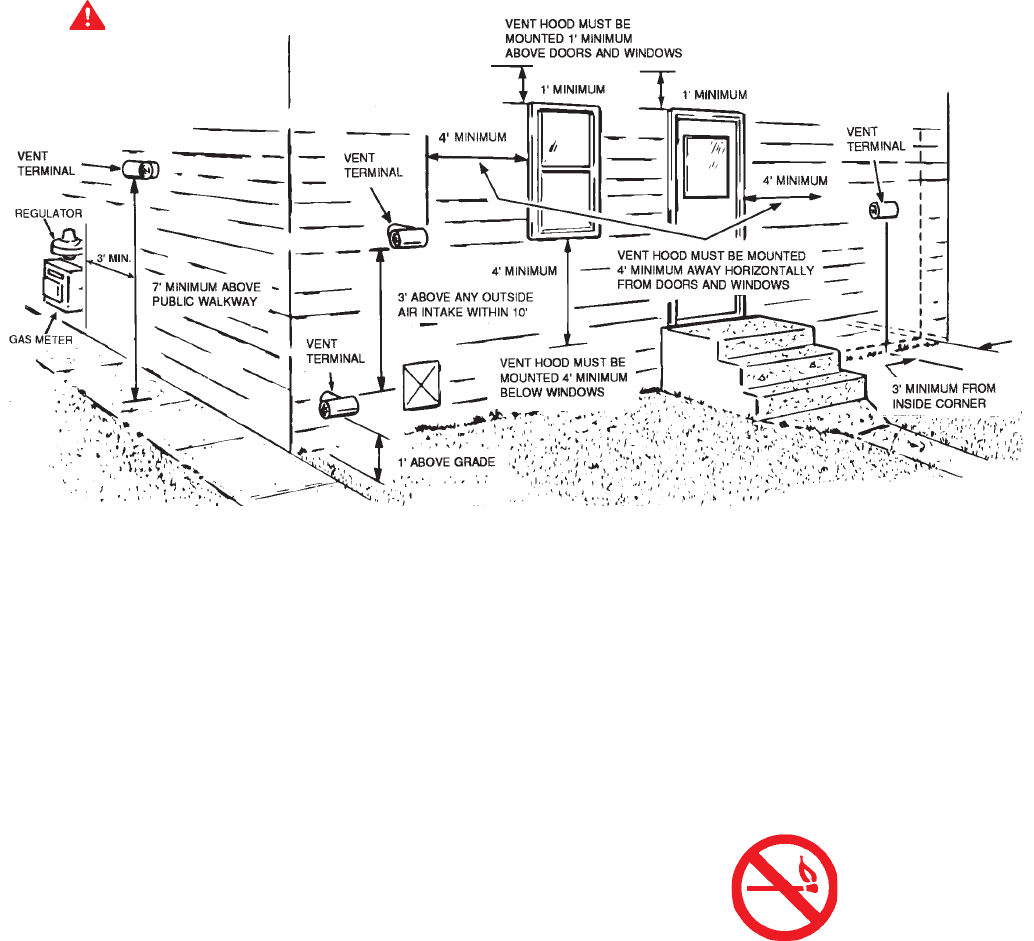

FIGURE 3

WARNING

VENT HOOD(S) MAY BE

EXTREMELY HOT

DURING OPERATION.