10

FIGURE 12

INSTALLATION OF VENT SYSTEM

WARNING

THE OPTIONAL INTAKE VENTING ARRANGEMENT AND THE EXHAUST

VENTING ARRANGEMENT MUST BE INSTALLED TO RUN DIRECTLY TO THE

OUTDOORS AND NOT IN ANY WAY BE CONNECTED TO ANOTHER

VENTING SYSTEM (I.E. FURNACE, DRYERS OR SPACE HEATERS). IT IS

CRUCIAL THAT THE VENTING ARRANGEMENT BE KEPT SEPARATE FROM

OTHER VENTING SYSTEMS. IF THIS WARNING IS IGNORED, AND THE

SYSTEM IS VENTED INCORRECTLY, IT MAY CAUSE IMPROPER OPERATION,

FIRE, EXPLOSION, OR ASPHYXIATION.

1. Plan the route of the vent system from the vent termination to the planned

location of the appliance. Layout the total vent system to use the minimum

of vent pipe and elbows possible.

2. The installer may add up to a MAXIMUM OF FIFTY (50) EQUIVALENT

feet of pipe to the exhaust venting arrangement. This addition of FIFTY

(50) EQUIVALENT feet of pipe on both the intake venting arrangement

and exhaust venting arrangement must include any 3 inch PVC elbows

which equals (5) EQUIVALENT feet of pipe.

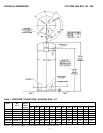

FIGURE 11

VERTICAL VENT TERMINAL INSTALLATION

IMPORTANT

WHEN TERMINATING THROUGH A ROOF, THE FOLLOWING

SPECIFICATIONS PERTAINING TO TERMINAL LOCATION MUST BE

FOLLOWED.

1. Proper support must be provided for all pipe protruding through the

roof.

2. The vertical roof terminations should be sealed with a plumbing roof

boot or equivalent flashing.

3. The intake vent termination and the exhaust vent termination must

penetrate the same side of roof.

4. The center line of the intake vent termination and the center line of the

exhaust vent termination must be no closer than 24" (inches).

5. The intake vent terminal and the exhaust vent terminal must be oriented

facing downward and the same direction.

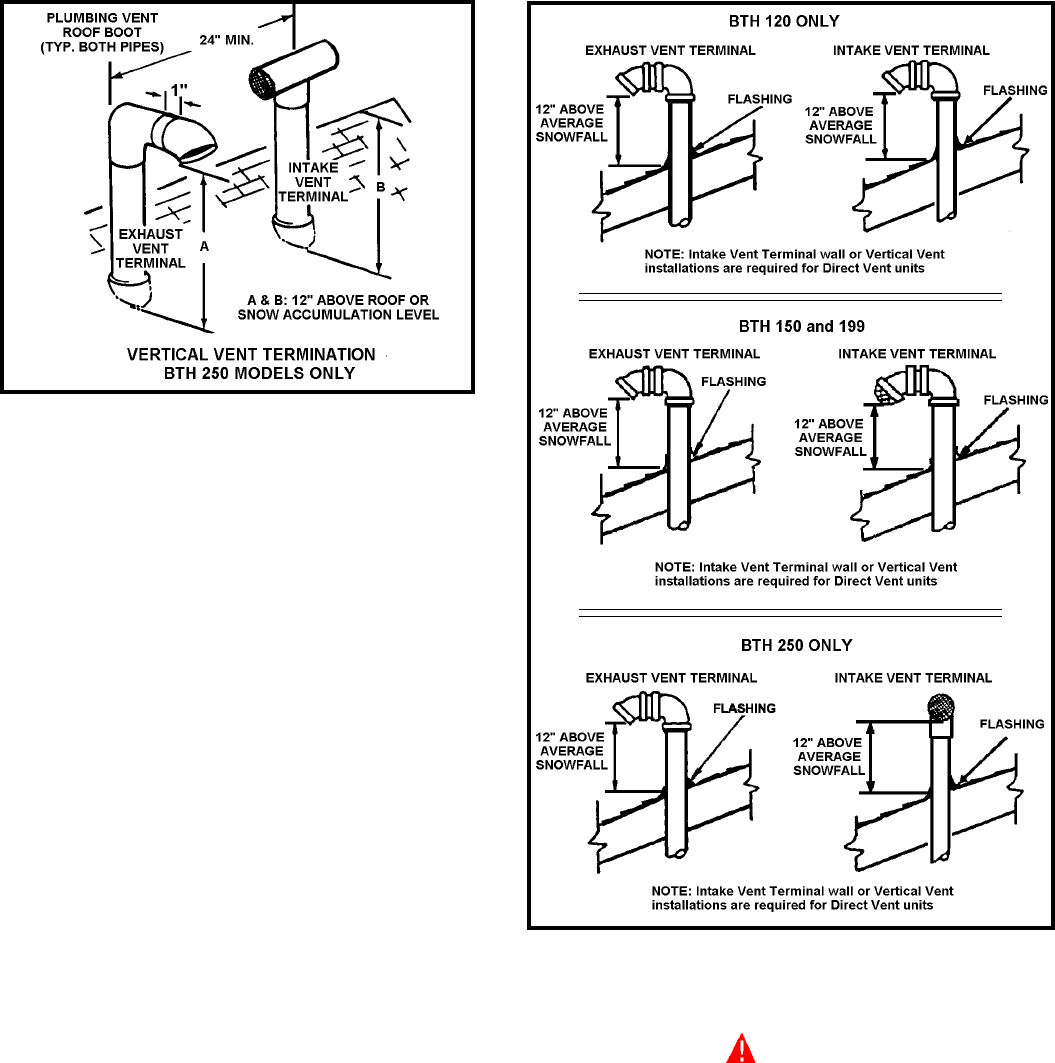

The specifications are displayed in Figure 11 & 12.

NOTE: Exhaust vent terminal is installed using the same procedure.

INSTALLATION SEQUENCE

NOTE: BEFORE BEGINNING INSTALLATION OF ANY VENT PIPE, READ

“VENT PIPE PREPARATION” SECTION ON PAGE 11.

1. After the points of termination have been determined, use the cover

plates as templates to mark the holes for the vent pipes to be inserted

through the roof.

2. Drill a pilot hole approximately one quarter inch outside of the marked

circle. This pilot hole is used as a starting point for a saws-all or sabre

saw blade. Cut around the marked circle staying approximately one

quarter inch outside the line. (This will allow the vent pipe to easily slide

through the opening). The resulting gap will be covered by the roof boot/

flashing.

3. Suspend the pipe through the center of the hole using proper support.

4. Slide roof boot or equivalent flashing over pipe and secure roof boot

equivalent flashing to roof.

5. Seal around flashing.

6. Terminate intake terminal and exhaust vent terminal facing down as

shown in Figure 12.