34

TABLE 20. RISK OF SCALDS.

TEMPERATURE TIME TO PRODUCE 2nd & 3rd

SETTING DEGREE BURNS ON ADULT SKIN

OVER 170°F (77°C) NEARLY INSTANTANEOUS

160°F (71°C) ABOUT 1/2 SECOND

150°F (66°C) ABOUT 1-1/2 SECONDS

140°F (60°C) LESS THAN 5 SECONDS

130°F (54°C) ABOUT 30 SECONDS

120°F (49°C) OR LESS MORE THAN 5 MINUTES

USE ANTI-SCALD VALVE(S) in the hot water system to reduce the

risks of scalding at points of use such as lavatories, sinks and

bathing facilities.

CONTROL SYSTEM

The EMC 5000 control system is a fully integrated, state of the art

electronic control system. It consists of sensors, output devices, a

power switch, a 24vac transformer, wiring and the following printed

circuit boards:

• Central Control Board (CCB), see Figure 17.

• Flame Control Board (FCB), see Figure 18.

• Power Distribution Board (PDB), see Figure19.

• User Interface Module (UIM), see Figure 21.

The CCB contains circuitry for both master control and flame control

for the first stage. The FCB's contains circuitry for control on up to

three additional stages. Dipswitches on the CCB and FCB are used

to configure the system. The User Interface Module (UIM)

communicates with the user through a set of touch pads and a 4-

line, 20-character LCD display. The PDB provides connection points

for input power, the water pump, and the transformer. It also

distributes power to the system and contains the system fuses.

Multiple-stage control is accomplished by means of an internal

communications network between the CCB and the FCB's. One

FCB is required for each stage beyond the initial first stage. The

CCB also contains an external communications system to allow

for connection to a PC, a modem, an EMS system, or something

similar. Through this connection multiple boilers can also be linked

together. CAUTION: The internal communications cables should

never be connected to the external communications connectors

and vice-versa.

There are several microcontrollers used on the boards. These

micros control the temperature and ignition control functions for

the boiler. Inherent in the design are the normal operating

sequences and safety features associated with a gas ignition

control system. The system continuously performs various

diagnostic tests to verify proper appliance and control operation.

Should an unsafe condition occur, the control will shut down the

burner and display a red fault light as well as indicate the cause of

the fault on the display. The operating programs for the system are

stored in permanent memory inside the micros. User-selectable

operating parameters and a history of detected faults are stored in

re-writable memory in the micros. A loss of power does not affect

either of the memories.

Inputs to CCB and FCB

Temperature Sensors:

• Temperature probes (CCB - outlet and either inlet or tank are

MANIFOLD PRESSURE

The manifold gas pressure is measured at the pressure tap on the

downstream side of the combination gas valve(s). For natural gas

the Manifold Pressure should measure 3.5" W.C. For propane (LP)

gas, the pressure should read 10" W.C.

IMPORTANT

UNDER NO CIRCUMSTANCES SHALL THE GAS PRESSURE

MEASURED AT THE BURNER MANIFOLD EXCEED THAT STATED

ON THE BOILER RATING PLATE. OVERFIRING WILL RESULT IN

DAMAGE TO THE BOILER, AS WELL AS INCREASED RISK OF

FIRE, SOOTING AND ASPHYXIATION.

ADJUSTMENTS

ON INITIAL STARTUP SOME ADJUSTMENTS ARE NECESSARY.

1. CHECK MANIFOLD AND INLET GAS PRESSURES.

2. CHECK THE INPUT. SEE NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR CAN/CSA - B149.1 (CURRENT EDITION) FOR

PROCEDURES.

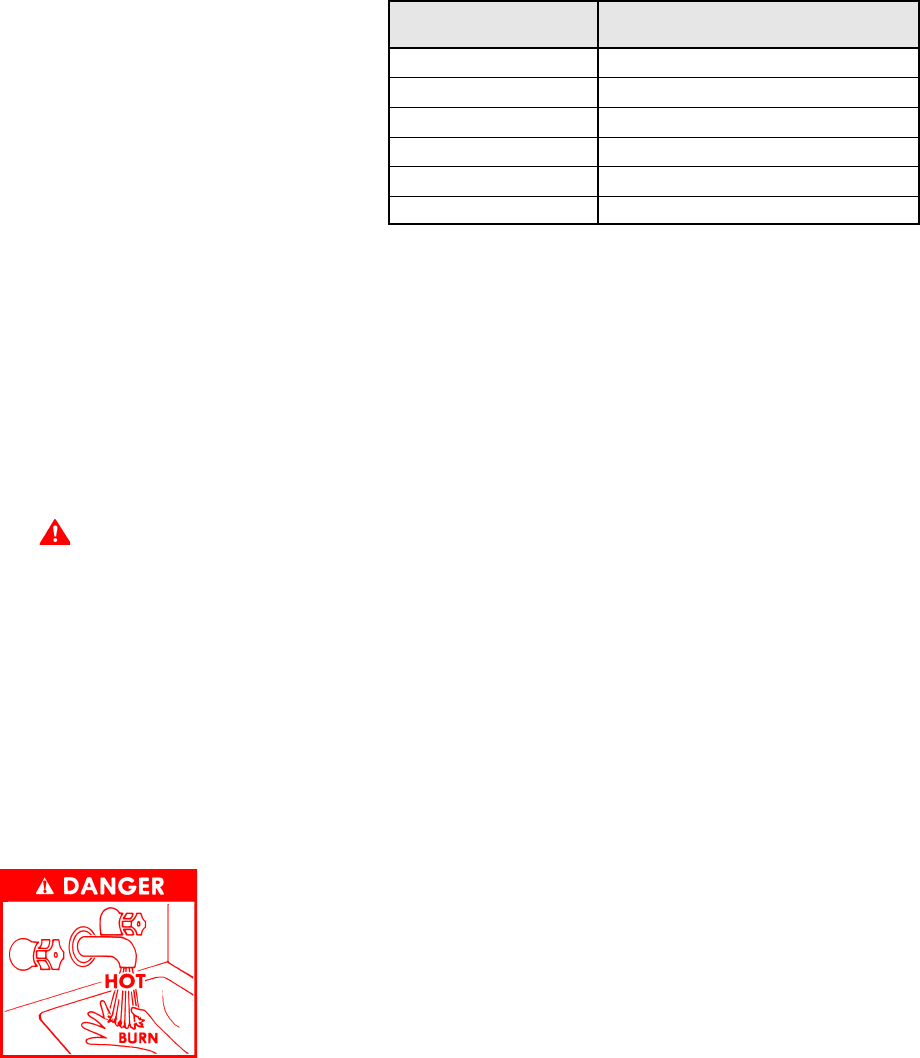

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD

BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/OR

DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS VARIES

WITH THE PERSON'S AGE AND TIME OF EXPOSURE. THE

SLOWER RESPONSE TIME OF CHILDREN, AGED OR DISABLED

PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW

SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW

THEIR OWN BATH WATER. NEVER LEAVE A CHILD OR DISABLED

PERSON UNATTENDED IN A BATHTUB OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET

TEMPERATURES.

IT IS RECOMMENDED IN DOMESTIC HOT WATER APPLICATIONS

THAT LOWER WATER TEMPERATURES BE USED TO AVOID THE

RISK OF SCALDING. IT IS FURTHER RECOMMENDED, IN ALL

CASES, THAT THE WATER TEMPERATURE BE SET FOR THE

LOWEST TEMPERATURE WHICH SATISFIES THE USER'S HOT

WATER NEEDS. THIS WILL ALSO PROVIDE THE MOST ENERGY

EFFICIENT OPERATION OF THE BOILER AND MINIMIZE SCALE

FORMATION IN THE HEAT EXCHANGER, THUS PROLONGING

THE LIFE OF THE BOILER.

SETTING THE WATER HEATER TEMPERATURE AT 120°F (49°C)

WILL REDUCE THE RISK OF SCALDS. SOME STATES REQUIRE

SETTINGS AT SPECIFIC LOWER TEMPERATURES. TABLE 20

ABOVE SHOWS THE APPROXIMATE TIME-TO-BURN

RELATIONSHIP FOR NORMAL ADULT SKIN.