11

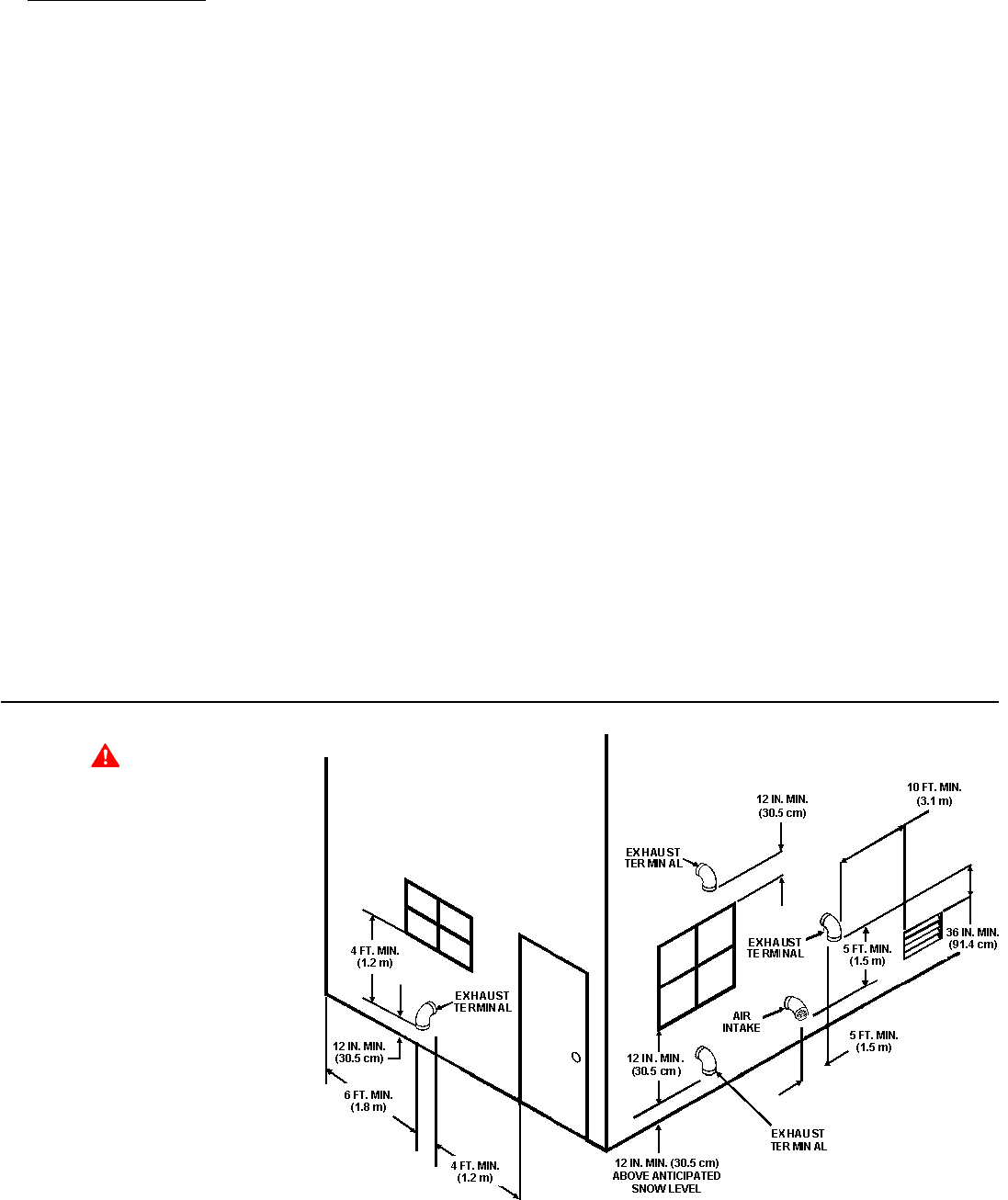

Figure 5. Vent Termination Installation Clearances

CAUTION

DIRECT VENTING INTO DEAD AIR SPACES

SUCH AS ALLEYS, ATRIUMS AND INSIDE

CORNERS CAN CAUSE RECIRCULATION OF

FLUE GASES. RECIRCULATION OF FLUE

GASES WILL CAUSE SOOTING, PREMATURE

FAILURE OF THE HEAT EXCHANGER AND

ICING OF THE COMBUSTION AIR INTAKE

DURING SEVERE COLD WEATHER. TO

PREVENT THE RECIRCULATION OF FLUE

GASES, MAINTAIN AS MUCH DISTANCE AS

POSSIBLE BETWEEN THE COMBUSTION AIR

INTAKE AND THE EXHAUST VENT TERMINAL.

STANDARD VENTING DIRECT VENT APPLICATIONS

Note: Venting system of other than

direct-vent appliance shall terminate at

least 4 ft. (1.2 m) below, 4 ft. (1.2 m)

horizontally from, or 1 ft. (30.0 cm)

above any door window or gravity air

inlet.

fireplace dampers and other gas burning appliances to their

previous conditions of use.

All boiler venting systems shall be installed in accordance with

the National Fuel Gas Code, ANSI Z223.1 or CAN/CSA-B149.1

(current edition), or applicable provisions of the local building

codes.

INTAKE/EXHAUST INSTALLATION REQUIREMENTS

1. The termination must be 12 inches (30.5 cm) above snow

or grade level whichever is higher.

2. Due to normal formation of water vapor in the combustion

process, horizontal terminations must not be located over

areas of pedestrian or vehicular traffic, i.e. public walkways

or over areas where condensate could create a nuisance

or hazard. This is especially true in colder climates where

ice buildup is likely to occur. A.O. Smith Corporation will

not be held liable for any personal injury or property

damage due to any dislodging of ice.

3. The exhaust terminal of the venting system must maintain

a minimum clearance of 4 feet (1.22 m) horizontally from,

and in no case above or below, unless a 4-foot horizontal

distance is maintained, from electric meters, gas meters,

regulators and relief equipment.

4. The minimum distance from inside corner formed by two

exterior walls is 6 feet (1.8 m) but 10 feet (3.1 m) is

recommended where possible.

5. Maintain a minimum distance of 4 feet (1.2 m) from any

soffit or eve vent to the exhaust terminal.

6. Maintain a minimum distance of 10 feet (3.1 m) from

any forced air inlet. Fresh air or make up air inlet such

as a dryer or furnace area is considered to be a forced

air inlet.

7. Avoid areas where condensate drainage may cause

problems such as above planters, patios, or adjacent to

windows where the steam from the flue gases may cause

fogging.

8. Select the point of wall penetration where the minimum

1/4" per foot (2 cm/m) of slope up can be maintained.

9. The through the wall termination kit is suitable for zero

clearance to combustible materials.

10. The mid point of the termination elbow must be a minimum

of 12 inches (30.5 cm) from the exterior wall.

SYSTEM INSTALLATION

GENERAL

If the system is to be filled with water for testing or other purposes

during cold weather and before actual operation, care must be taken

to prevent a down draft entering the boiler or freezing air from contacting

the system. Failure to do so may cause the water in the system to

freeze with resulting damage to the system. Damage due to freezing

is not covered by the warranty.

Good practice requires that all piping, etc., be properly supported.

The boilers described in this manual may be used for space (hydronic)

heating or for the heating of potable water. If the heater is to be used for

hydronic space heating, follow the instructions on pages 16-17 given for

equipment required for installation as in Figure 10. However, if units

are to be used for heating potable water, the information describing

specific systems is found on pages 18-20; see Figures 11 and 13.

Installations must comply with all local codes.

INSTALLATION AS BOILER REPLACEMENT

Installation as boiler replacement on an old system with large water