24

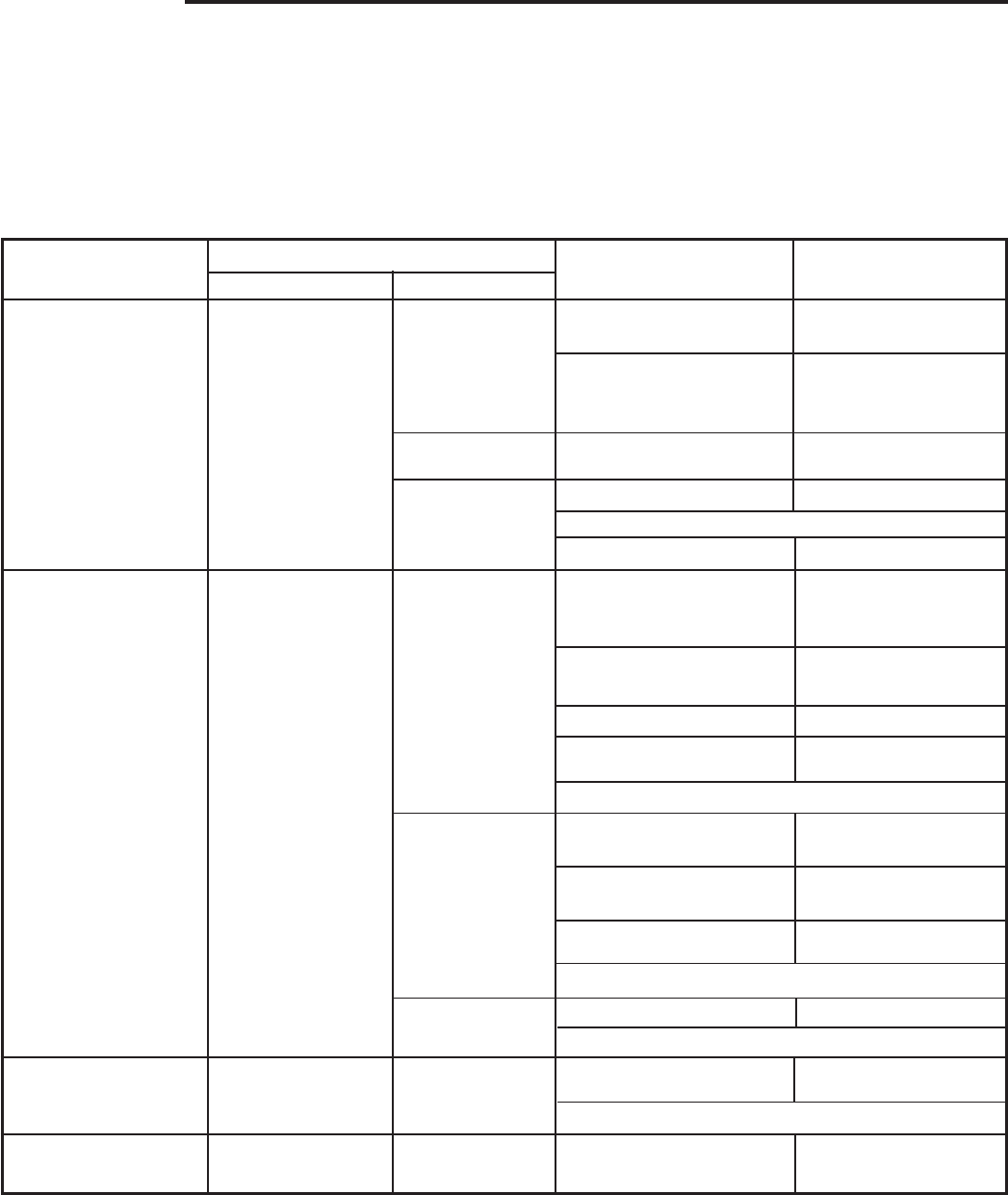

CHART 1 - CER-TEMP 80 RECOVERY SYSTEM CHECKOUT PROCEDURE

(Use this checkout for Cer-Temp 80 Recovery Systems)

CHECKOUT

The checkout sequence should be used as an on-the-job trouble-

shooting guide to identify the cause of incorrect system operation

and suggest a remedy for its correction.

Because improper piping and wiring can result in unsatisfactory

system performance, it is suggested that the installation be

examined before using the checkout procedure. Be sure to refer

to the correct piping - wiring diagram and checkout for the type of

system that is installed.

The system should be filled with water, purged of air, valves

properly set and utilities connected and ready to operate.

REMOVING SILICATE

Ammonium bifluoride flakes (NH

4

FlHF) are used in conjunction

with A. O. Smith UN•LIME delimer and pump type deliming kit,

part no. 4930, to delime and remove siliceous materials from

copper coil water heaters.

• The part no. 4920 pump contained in the deliming kit is

equipped with a titanium shaft. This shaft will not withstand

ammonium bifluoride solutions and must be replaced with a

stainless steel shaft, part no. 4926.

Ammonium bifluoride flakes should be purchased locally from

chemical suppliers. Contact your dealer, distributor or

A. O. Smith Water Products Company for additional information.

SYSTEM OPERATION

Checkout Sequence Contact Incorrect Cause Remedy

Set tank temperature Circulating pump Pump and burner Tank temperature control Reduce differential.

control 20° (11°C) below and burner shut remain on. differential wide.

tank water temperature off.

With thermal Tank temperature control Replace.

balancer, pump off defective.

delay of approx-

imately 2 minutes. System wiring is incorrect. Correct wiring.

Circulating pump Pump wired for continuous Correct wiring.

on. operation.

Burner on. See intermittent pilot system troubleshooting chart 2.

Gas valve stuck or defective. Correct or replace valve.

System wiring in incorrect. Correct wiring.

Set tank temperature Circulating pump Circulating pump Automatic gas shutoff Replace. (If problem

control 20° (11°C) above and burner on. on. control calibrated too low proven to be at this

tank water temperature. or differential too wide. control by applying

jumper to terminals.)

If system has been in See preventive

extended use it may maintenance.

have lime build-up.

System wiring is incorrect. Correct wiring.

Gas valve or wiring Check wiring repair or

defective. replace valve.

See intermittent pilot system trouble-shooting chart 2.

Circulating pump Tank temperature control Reduce differential. A 5°

and burner off. differential too great. differential is generally

used.

Power off or system wiring Check power supply and

is incorrect. wiring.

Tank temperature control Replace.

defective.

See intermittent pilot system trouble-shooting chart 2.

Burner on. System wiring is incorrect. Replace.

See intermittent pilot system trouble-shooting chart 2.

Heater outlet water Circulating pump Circulating pump Automatic gas shutoff Replace.

temperature exceeds on. and burner on. control defective.

210°F.

See intermittent pilot system trouble-shooting chart 2.

Set tank temperature System maintains.

control for desired water desired water

temperature. temperature.