26

CONTROL SYSTEM

DESCRIPTION OF MULTI-STAGE FIRING SYSTEM

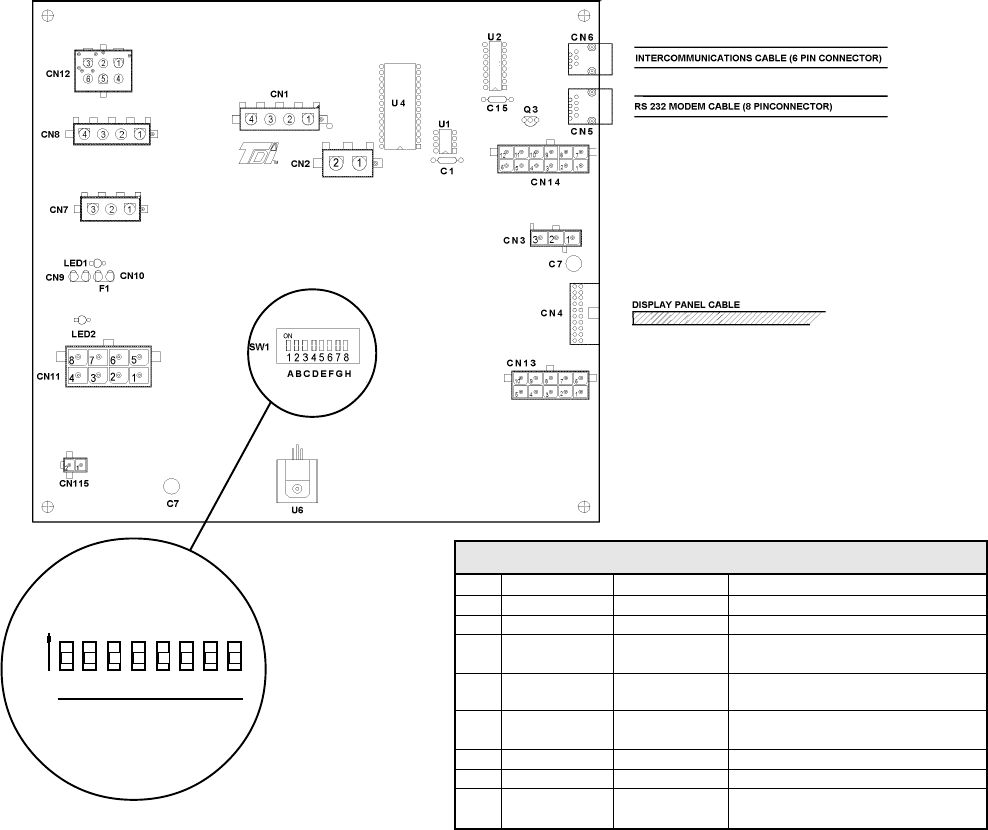

The Central Control Board (CCB) is responsible for staging the

Ignition Control Boards (ICB) and monitoring safety limit devices,

control of circulation pump, power vent, alarm output and IRI gas

valves (only on IRI models). The thermostat also resides on the

CCB with inputs available for inlet, outlet and tank temperature

probes as well as an input for a remote 24 VAC thermostat. The

CCB has a display interface which connects to the Display Board

to show system status and failures. The CCB also has a set of DIP

switches which allows the user to control several system

parameters. (See Figure 14.)

Each stage requires an Ignition Control Board (ICB) which is

responsible for controlling a combustion blower, hot surface igniter

and gas valve. Each ICB is capable of monitoring gas valve power,

gas valve relay, flame sense and igniter current. The ICB is

designed to communicate with the Central Control Board (CCB).

Each ICB consists of identical hardware and software. Each stage

ICB is made unique through the use of circuit board jumpers which

allow the user to control such variables as stage identification and

blower/igniter usage. (See Figure 15 for jumper configurations.)

These jumpers are pre-set at the factory and should only be

adjusted by a qualified service technician.

The Display Board allows the end user to monitor water temperature,

set-points, differentials, options, fault indications and error codes.

Display Board pushbuttons labeled "ADJUST", "SELECT" AND

"ENTER/RESET" enable the user to adjust set-points, differentials,

post-circulate time, reset the cycle count and reset the control

system during lock-out. Changes made to programmable features

are stored in non-volatile memory.

DIA-SCAN II DISPLAY BOARD OPERATING PROCEDURES

The Display Board provides a user-friendly interface to the Central

Control Board. With the Display Board, the user can control

appliance functions and view the overall operating status of the

appliance. If an error condition occurs, the Display Board will indicate

the nature of the fault by illuminating a red LED. The display will

further define the fault by illuminating a red LED corresponding to

the stage on which the fault has occurred. Red and green LEDs

are associated with each stage to indicate either a fault or normal

operation. If the fault continues until the unit "locks out", the display

will show a three digit code in addition to the red LEDs. (See Table

19 for error code chart.) Under normal operating conditions, the

four digit LED display on the Display Board will continuously illustrate

the water temperature sensed at the inlet temperature probe. If dip

Figure 14. Central Control Board's Dip Switch Configuration and Options

ON

SW1

1 2 3 4 5 6 7 8

AHFEDCBG

DIP SWITCH CONFIGURATION TABLE

SW1 OFF ON SELECTION:

A 3 STAGE 4 STAGE EITHER 3 OR 4 STAGE SYSTEM

B 3 TRIALS 1 TRIAL EITHER 3 OR 1

C NO IRI IRI WHETHER SYSTEM IS IRI OR

GAS VALVE GAS VALVE STANDARD

D INLET TANK INLET OR TANK AS

CONTROLLING PROBE

E NO EXTERNAL EXTERNAL WHETHER EXTERNAL

THERMOSTAT THERMOSTAT THERMOSTAT IS USED

F OUTLET 210°F OUTLET 240°F OUTLET MAXIMUM TEMPERATURE

G 190°F 220°F MAX. SET-POINT TEMPERATURE

H DEGREES °F DEGREES °C EITHER °F OR °C FOR DISPLAYED

TEMPERATURE