14

STANDARD (VERTICAL) VENTING, CATEGORY I

THIS BOILER MAY BE VENTED ACCORDING TO TABLE 7 (ALSO

SEE FIGURE 5). AT LEAST TYPE B VENTING MUST BE USED

WITH THE STANDARD VENTING OPTION (thru-the-roof) USING

THE NATIONAL FUEL GAS CODE VENT TABLES.* TYPE B VENT

PIPE

CANNOT BE USED IF THE BOILER IS VENTED

HORIZONTALLY OR AS A DIRECT VENT (SEE PAGES 11

THROUGH 13). ALL LOCAL UTILITY, STATE/ PROVINCIAL,

REGULATIONS ON VENTING MUST BE FOLLOWED.

VENT SIZING, INSTALLATION AND TERMINATION SHALL BE IN

ACCORDANCE WITH THE

NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR CAN/CSA-B149.1 and .2 (AND LATEST ADDENDA).*

Vent connections must be made to an adequate stack or chimney

and shall be in accordance with the

National Fuel Gas Code, ANSI

Z223.1 or CAN/CSA-B149.1and .2 (and latest addenda) or

applicable provisions of the local building codes. Size and install

proper size vent pipe.

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet [1.2 m]),

noncombustible hangers suitable for the weight and design of the

materials employed to prevent sagging and to maintain a minimum

upward slope of 1/4" per foot (2 cm/m) from the boiler to the vent

terminals. Dampers or other obstructions must not be installed in

the vent. Be sure that the vent connector does not extend beyond

the inside wall of the chimney.

STANDARD (HORIZONTAL) VENTING, CATEGORY III

Vent sizing, installation and termination shall be in accordance

with the

NATIONAL FUEL GAS CODE, ANSI Z223.1 OR

CAN/CSA-B149.1 AND .2 (LATEST EDITIONS). If applicable, all

local, utility, state/provincial regulations on venting must be followed.

See table 8 for venting specifications. The exhaust vent pipe must

be of a type listed for use with Category III gas burning heaters

such as "Saf-T-Vent" manufactured by Heat-Fab Inc.

For Category III installations, It is important that the Installed vent

be airtight. Please insure that all joints are sealed properly during

installation.

DIRECT VENT VERTICAL AND HORIZONTAL VENTING

For direct vent applications this boiler may be vented according to

tables 9 and 10. For category III applications, the exhaust vent pipe

must be special gas vent pipe listed for use with category III gas

burning heaters such as "Saf-T-Vent" manufactured by Heat-Fab

Inc. This vent system must be 100% sealed with a condensate

trap located as close to the boiler as possible.

When sizing exhaust piping and intake air piping, 90-degree elbows

are equivalent to 10 feet (3.1 m) of straight pipe and 45-degree

elbows are equal to 5 feet (1.5 m) of straight pipe.

The intake air piping can be PVC, CPVC, ABS or any suitable intake

air piping that can be sealed.

Combustion air from outside the building ducted to boiler air inlet

(Ducted Air Application) cannot be used in rooms with negative

pressure.

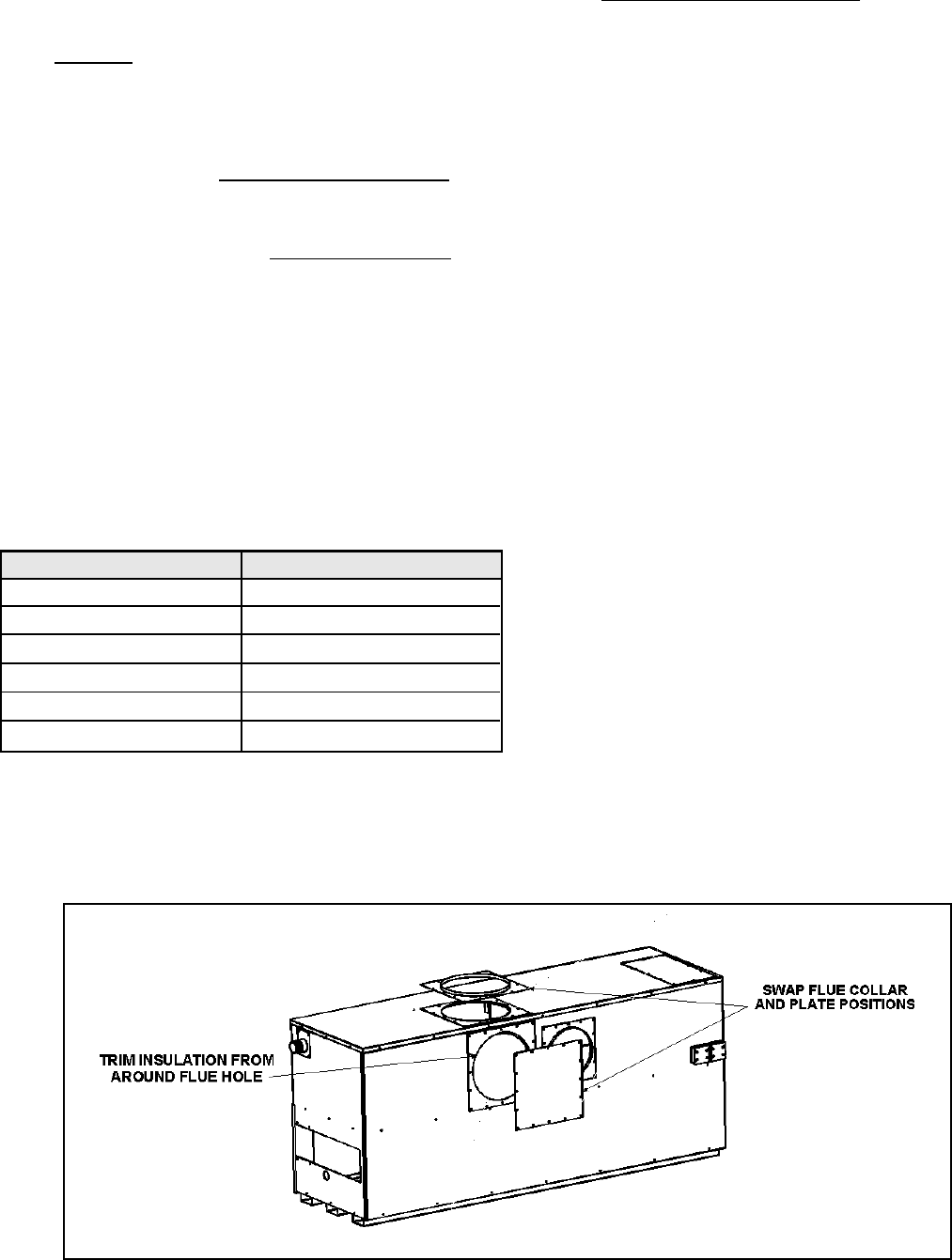

HORIZONTAL VENT INSTALLATION

This boiler can be vented through the rear of the cabinet with the

use of the Fluebox and vent adaptor. Any of the previous venting

configurations can be installed with rear connections.

To change the unit to rear exhaust:

1. The vent collar and cover plates must be removed from the top

and rear of the unit.

2. Trim the insulation from around the rear flue hole in the jacket

and the fluebox. Support insulation from inside the fluebox to

facilitate cutting. Use safety precautions such as gloves. Place

the gasket and vent adaptor in the horizontal position. Place the

gasket and flue plate in the vertical position as shown in

figure 9.

Figure 9. Switching from Vertical to Horizontal Venting

Table 11: VENT CONNECTION

VENT CONNECTOR MODEL NUMBER

G(W,B) 1000 10" (25.4 cm)

G(W,B) 1300 12" (30.5 cm)

G(W,B) 1500 12" (30.5 cm)

G(W,B) 1850 14" (35.6 cm)

G(W,B) 2100 14" (35.6 cm)

G(W,B) 2500 16" (40.6 cm)

For vent arrangements other than table 7 and for proper boiler

operation, a barometric damper is required to maintain draft

between -0.02" W.C.. and -0.04" W.C. at 2 feet (0.6 m) above the

boiler vent collar.