16

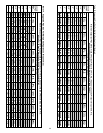

Figure 10. Single or Multiple Boiler Installation Diagram

The circuits should be spaced on the header at a minimum of

3" (7.6 cm) center to center. Install a balancing cock in each return

line.

Manifold headers are recommended for split systems with or

without zone valves and also those installations with zone

circulators. If the system is to be split at remote points, good practice

requires special attention be given to main pipe sizing to allow

balancing of water flow.

COOLING PIPING

When the boiler is used in conjunction with a refrigeration system

it must be installed so that the chilled medium is piped in parallel

with the boiler. Appropriate valves, manual or motorized, must be

provided to prevent the chilled medium from entering the boiler.

Water temperature in the heating system must be reduced to less

than 100°F before cooling system is started, or damage to the

chiller unit may occur.

If the boiler is connected to chilled water piping or heating coils

exposed to refrigerated air, the boiler piping system must be

equipped with flow control valves or other automatic means to

prevent gravity circulation through the boiler during the cooling cycle.

Primary/secondary pumping of both the chiller(s) and the boiler(s)

is an excellent winter-summer change-over method, because

cooling flow rates are much more than heating flow rates. In this

way each system (heating or cooling) is circulated independently.

SPACE HEATING APPLICATIONS

Controlling of these systems is decided mainly by the type of

building system controlling that is desired. A single boiler

installation might be controlled directly from space temperature

thermostat(s). Multiple boiler installations are more effective when

the boilers are sequenced in and out of operation by some form of

main water temperature controller. With one or two boilers, individual

control settings at progressive temperature may be used. For more

than two boilers, electronic sequencing controlling is

recommended.

Individual controls, or the separate stages of a step controller,

should fire a boiler and also start the boiler loop circulator whenever

that boiler is fired. Some large installations may require the firing

of more than one boiler per stage.

The system or primary circulator may or may not be controlled by

the boiler sequencer. When this pump is operated through the first

switch of any type of step controller, care should be taken to

determine if a motor starter is needed due to insufficient switch

capacity.

If the primary pump is controlled by a manual switch or any other

controllers, the electric current supply to the boiler group should be

through the primary pump controller. The fast response of

A.O. Smith boilers eliminates any need to maintain boiler

temperature when the system is satisfied. Wiring should always

prevent firing of boiler(s) when there is no water flow in the

mains.

Installation diagrams show safety flow switches in the outlet piping

from each boiler as good protection against any boiler being fired

when the boiler loop circulator is not in operation. These safety flow

switches will also provide some protection if there is a loss of water.

Multiple boiler installations are especially adapted to the use of

outdoor reset for main water temperatures. This feature is not