46

VENTING SYSTEM INSPECTION

At least once a year a visual inspection should be made of the venting

system. You should look for:

1. Obstructions which could cause improper venting. The combustion

and ventilation air ow must not be obstructed.

2. Damage or deterioration which could cause improper venting or

leakage of combustion products.

Be sure the vent piping is properly connected to prevent escape of

dangerous ue gasses which could cause deadly asphyxiation.

Obstructions and deteriorated vent systems may present serious

health risk or asphyxiation.

Chemical vapor corrosion of the ue and vent system may occur

if air for combustion contains certain chemical vapors. Spray can

propellants, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chemicals, calcium and sodium chloride,

waxes, bleach and process chemicals are typical compounds which

are potentially corrosive.

If after inspection of the vent system you found sooting or

deterioration, something is wrong. Call the local gas utility to correct

the problem and clean or replace the ue and venting before

resuming operation of the water heater.

ANODE ROD INSPECTION

The anode rod is used to protect the tank from corrosion. Most hot

water tanks are equipped with an anode rod. The submerged rod

sacrices itself to protect the tank. Instead of corroding the tank,

water ions attack and eat away the anode rod. This does not affect

the water’s taste or color. The rod must be maintained to keep the

tank in operating condition.

Anode deterioration depends on water conductivity, not necessarily

water condition. A corroded or pitted anode rod indicates high water

conductivity and should be checked and/or replaced more often than

an anode rod that appears to be intact. Replacement of a depleted

anode rod can extend the life of your water heater. Inspection should

be conducted by a qualied technician, and at a minimum should be

checked annually after the warranty period.

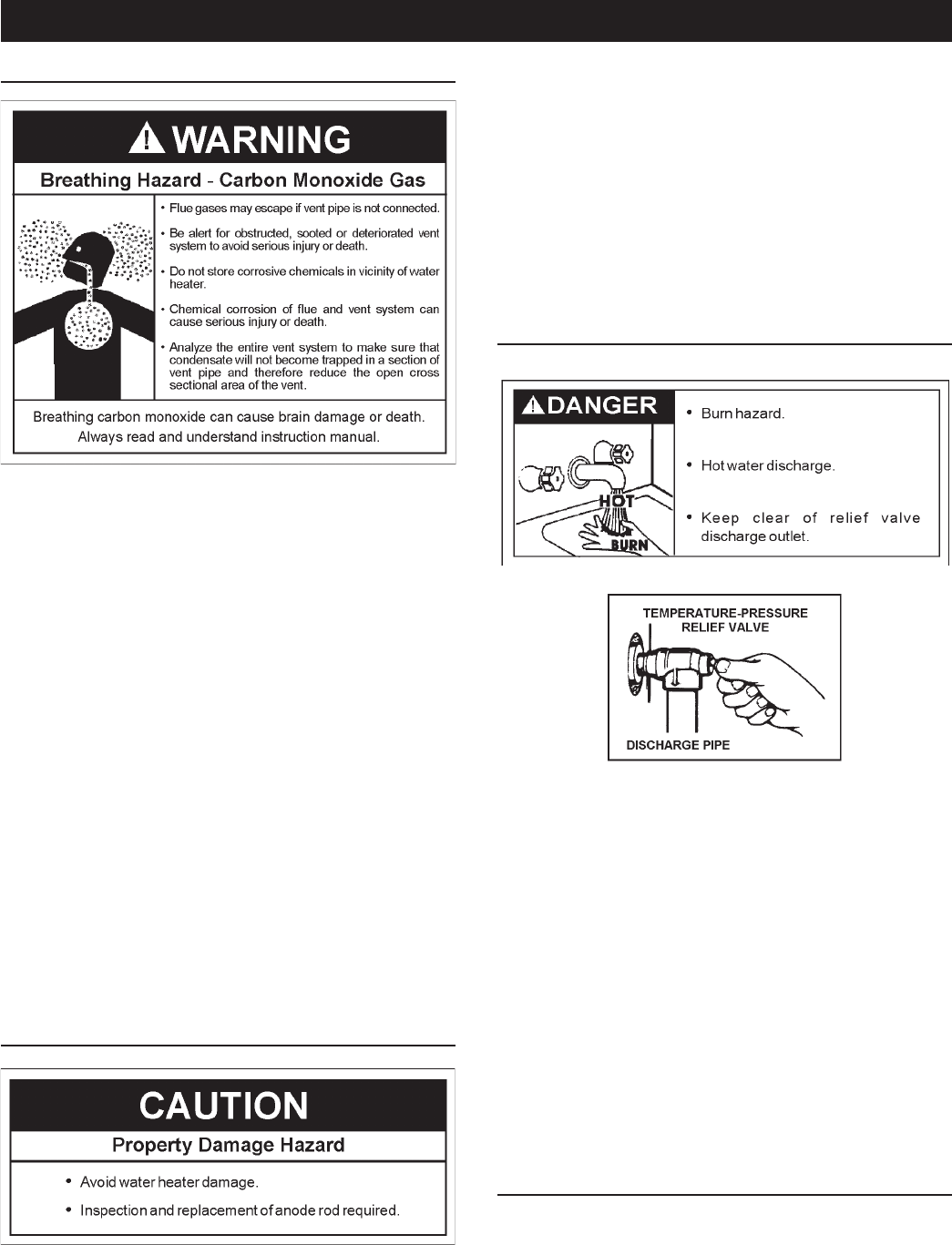

TEMPERATURE-PRESSURE

RELIEF VALVE OPERATION

FIGURE 36.

When checking the temperature-pressure relief valve operation,

make sure that (1) no one is in front of or around the outlet of the

temperature-pressure relief valve discharge line, and (2) that the

water discharge will not cause any property damage, as the water

may be extremely hot, see Figure 36.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater, follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

If the temperature-pressure relief valve on the appliance weeps or

discharges periodically, this may be due to thermal expansion. You

may have a check valve installed in the water line or a water meter

with a check valve. Consult your local water supplier or a qualied

service agency for further information. Do not plug the temperature-

pressure relief valve.

DRAINING AND FLUSHING

It is recommended that the water heater storage tank be drained and

ushed every 6 months to reduce sediment buildup. The water heater

should be drained if being shut down during freezing temperatures.

See Figure 1, Features And Components in this manual for the

location of the water heater components described below.

PERIODIC MAINTENANCE