5

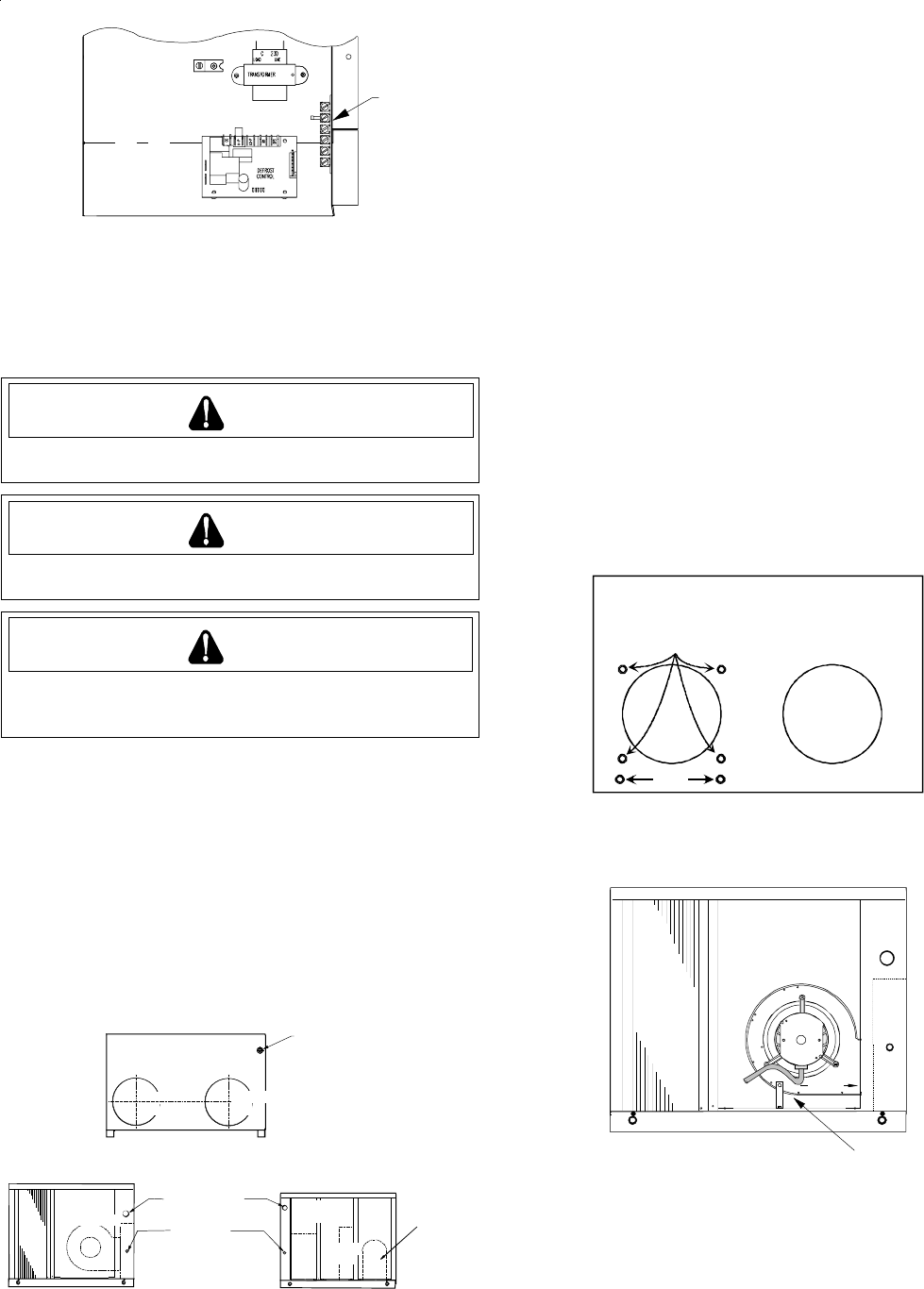

Low Voltage

Terminal Strip

Figure 4 - Low Voltage Connection

Unit Control Box

Refer to the unit wiring diagram for electrical connections. When

installed, the unit must be electrically grounded in accordance with

local codes or in the absence of local codes, with the National Elec-

trical Code, ANSI/NFPA No. 70, and/or the CSA C22.1 Electrical

Code, if an external source is utilized.

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK, WIRING

MUST BE PROPERLY GROUNDED.

CAUTION

T

O AVOID PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, USE

ONLY COPPER CONDUCTORS.

CAUTION

T

O PREVENT IMPROPER AND DANGEROUS OPERATION DUE TO WIRING

ERRORS, LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

CONTROLS.

V

ERIFY PROPER OPERATION AFTER SERVICING.

The best protection for the wiring is the lowest rated fuse or circuit

breaker which will supply power to the unit during normal operation

without nuisance trips. Such a device will provide maximum circuit

protection. DO NOT EXCEED THE MAXIMUM OVERCURRENT

DEVICE SIZE SHOWN ON UNIT DATA PLATE.

All line voltage connections must be made through weatherproof

fittings. All exterior power supply and ground wiring must be in ap-

proved weatherproof conduit. Low voltage wiring from the unit con-

trol panel to the thermostat requires coded cable.

FLEXIBLE WIRING SETUP

Line and low voltage wiring can enter the unit from either

side.

ELECT.

CONTROL

BOX

EVAP

COIL

COMPRESSOR

LOW

VOLTAGE

REAR VIEW

SIDE VIEW

ELECTRICAL

SIDE VIEW

BLOWER

ELECTRICAL

SUPPLY

AIR

RETURN

AIR

HEATER

KIT

For knockout locations, see dimension drawing in the Product Data

Book applicable to your model* . Use the Single Point wiring kit to

add further flexibility to the installation wiring.

UNIT VOLTAGE

The unit transformer is factory connected for 230V operation. If the

unit is to operate on 208V, reconnect the transformer primary lead

as shown on the unit wiring diagram.

CIRCIR

CIRCIR

CIR

CULCUL

CULCUL

CUL

AA

AA

A

TINTIN

TINTIN

TIN

G AIR AND FILG AIR AND FIL

G AIR AND FILG AIR AND FIL

G AIR AND FIL

TERTER

TERTER

TER

SS

SS

S

DOWNSHOT AIRFLOW CONVERSION

Units are shipped from the factory ready for horizontal airflow. These

units can be easily converted from horizontal to downshot airflow

delivery. If conversion to vertical airflow is necessary, proceed as

follows:

BLOWER ROTATION

The first step in the conversion is to rotate the blower assembly for

downshot airflow. After rotating the blower assembly, the blower motor

must be oriented as shown in Figure 7 with the motor wires at the

bottom. This keeps condensate from puddling inside the blower motor

and causing motor failure. If the motor is not oriented correctly, loosen

the motor belly band and rotate the motor to the correct position,

then retighten the motor belly band.

1. Cut insulation around bottom openings and remove panels

from the bottom of the unit, saving the screws holding the

panels in place.

2. From the rear of the unit, remove the four screws securing

the blower assembly in place and loosen the two screws

directly below the duct opening (Figure 5).

Remove

Loosen

Figure 5 - Duct Removal

3. Remove the clamp securing the blower assembly to the

bottom of the unit. The clamp and screws may be discarded

(Figure 6).

Remove

}

{

Airflow

Figure 6 - Clamp Removal

4. Rotate the blower assembly 90° clockwise, setting the blower

assembly outlet on the bottom of the unit and secure with two

screws removed in step 2 (Figure 7) .

5. Tighten the two screws below the duct opening that were

loosened in step 2.

NOTE: To keep condensate from collecting inside the blower motor,

ensure the motor is oriented with its leads exiting at the bottom of

the motor (Figures 5 and 6).