036-21687-002-A-1105

Unitary Products Group 43

GUIDE SPECIFICATIONS

GENERAL

Units shall be manufactured by York International Unitary

Products Group in an ISO 9001 certified facility.

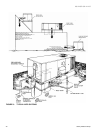

York's Sunline Magnum™ units are convertible single pack-

age units. Although the units are primarily designed for curb

mounting on a roof, they can also be slab-mounted at ground

level or set on steel beams above a finished roof. Cooling

only, cooling with gas heat and cooling with electric heat

models are avail

able with a wide variety of factory-mounted

options and field-installed accessories to make them suitable

for almost every application. All units are self-contained and

assembled on full perimeter base rails with holes in the four

corners for overhead rigging. Every unit is completely piped,

wired, charged and tested at the factory to simplify the field

installation and to provide years of dependable operation. All

models (including those with a

n economizer) are suitable for

either bottom or horizontal duct connections. Models with

power exhaust are suitable for bottom duct connections only.

For bottom duct, remove the sheet metal panels from the

supply and return air openings through the base of the unit.

For horizontal duct, remove the supply and return air panels

on the rear of the unit.

All non-Scroll compressors include crankcase heaters and all

compressors have internal pressure relief. Every refrigerant

circuit includes a liquid line filter-drier, a discharge line high

pressure switch and a suction line with a freezestat and low

pressure/loss of charge switch.The unit control circuit

includes a 75 VA transformer, a 24-volt circuit breaker and a

relay board with a compressor lockout circuit, a terminal strip

for thermostat wiring, plus an additional set of pin connectors

to simplify the interface of additional field controls. All models

are CSA listed. All models include a 1-yea

r limited warranty

on the complete unit. Compressors and electric heater ele-

ments carry a 5-year warranty. Aluminized steel and Stainless

steel tubular heat exchangers carry a 10-year warranty.

DESCRIPTION

Units shall be factory-assembled, single packaged, Electric

Cooling/Gas Heat, Electric Cooling/Optional Electric Heat

and designed for outdoor mounted installation.

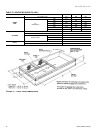

The 3 ton, 4 ton and 5 ton units shall have minimum SEER

rating of 13. They shall have built-in field convertible duct

connections for down discharge supply/return or horizontal

discharge supply/return, and be available with factory

installed options or field installed accessories. The units shall

be factory w

ired, piped, charged with R-22 refrigerant and

factory tested prior to shipment. All unit wiring shall be both

numbered and color coded. All units the cooling performance

shall be rated in accordance with DOE and ARI test proce-

dures. Units shall be CSA listed, classified to ANSI Z21.47,

UL 1995/CSA No. 236 standards.

UNIT CABINET

Unit cabinet shall be constructed of G90 galvanized steel,

with exterior surfaces coated with a non-cha

lking, powdered

paint finish, certified at 1000 hours salt spray test per

ASTMB117 standards. Indoor blower section shall be insu-

lated with a minimum 1/2” thick insulation, coated on the air-

side. Aluminum foil faced insulation shall be used in the

furnace compartment and be fastened with ridged fasteners

to prevent insulation from entering the air stream. Cabinet

panels shall be “lar

ge” size, easily removable for servicing

and maintenance. Full perimeter base rails shall be provided

to assure reliable transit of equipment, overhead rigging and

proper sealing on roof curb applications. Disposable 1" filters

shall be furnished and be accessible through a removable

access door, sealed airtight. Units filter track shall be

designed to accommodate either 1" or 2" filters. Fan perfor-

mance measuring

ports shall be provided on the outside of

the cabinet to allow accurate air measurements of evaporator

fan performance without removing panels or creating air by-

pass of the coils. Condensate pan shall be internally sloped

and conform to ASHRAE 62-89 self-draining standards. Con-

densate connection shall be a minimum of 3/4” I.D. female

and be a ridged mount connection.

INDOOR (EVAPORATOR) FAN ASSEMBLY

The indoor f

an shall be a factory installed belt drive assembly

that includes an adjustable pitch motor pulley. Job site

selected (B.H.P.) brake horsepower shall not exceed the

motors nameplate horsepower rating, plus the service factor.

Units shall be designed not to operate above service factor.

Fan wheel shall be double-inlet type with forward-curved

blades, dynamically balanced to operate smoothly throughout

the entire range of operation. Airflow design sha

ll be constant

air volume. Bearings shall be sealed and permanently lubri-

cated for longer life and no maintenance.

OUTDOOR (CONDENSER) FAN ASSEMBLY

The outdoor fan shall be of the direct-driven propeller type,

discharge air vertically, have aluminum blades riveted to a

corrosion resistant steel spider bracket and sha ll be dynami-

cally balanced for smooth operation. The outdoor fan motor

shall be totally enclosed with permanently lubricated bear-

ings, internally protected

against overload conditions and

staged independently.

REFRIGERANT COMPONENTS

Compressor:

a. Shall be internally protected with internal high-pres-

sure relief and over temperature protection.

b. Shall have internal spring isolation and sound muf-

fling to minimize vibration and noise, and be exter-

nally isolated on a dedicated, independent

mounting.

Coils:

a.Evaporator and condenser coils shall have alumi-

num plate fins mech

anically bonded to seamless

internally enhanced copper tubes with all joints