9

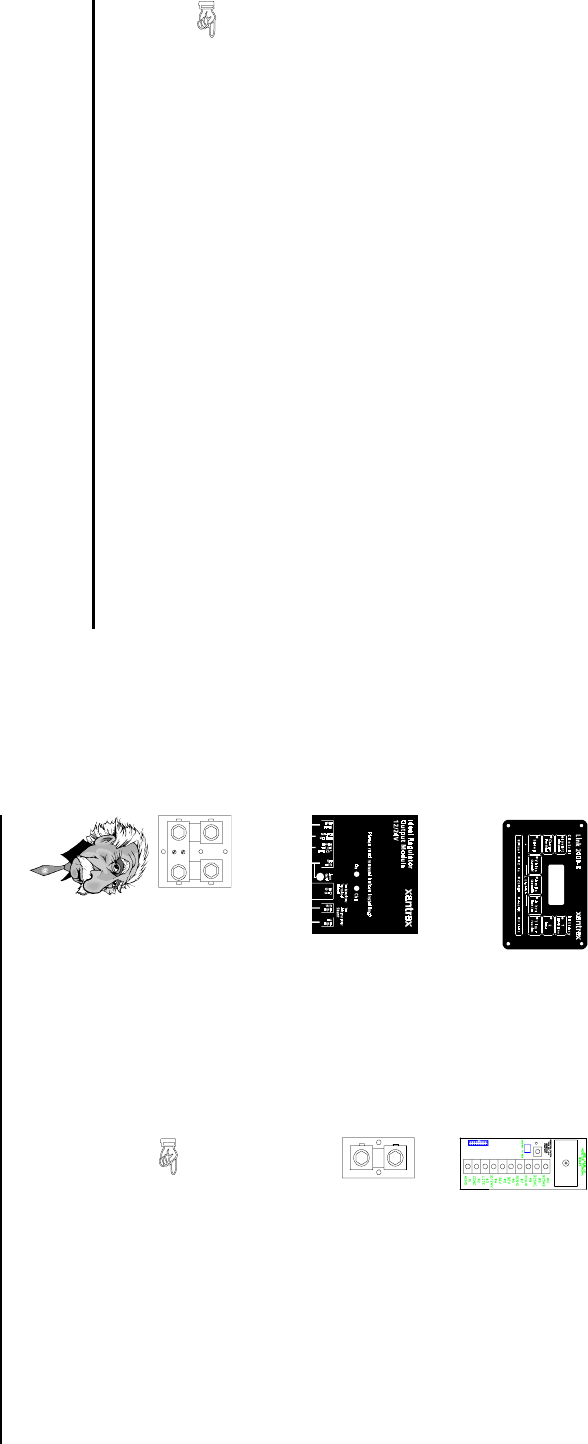

4) The Monitor Terminal Board: The

wiring for battery monitoring terminates

here. The ribbon cable from the meter

plugs into this board. It also has a RJ-45

jack on it for the Ideal Regulator Module.

1) The LINK 2000-R

Meter: Contains the micro-

processor and display. The

actual regulation program is

in the meter. It is terminated

with a ribbon cable. It also has

a RJ-11 jack for the remote

cord to the inverter/charger.

WIRING INSTRUCTIONS

Refer to the wiring diagram while using these instructions.

There are several components to LINK 2000-R METERS:

2) The Ideal Regulator

Output Module: Supplied

with a harness that connects

to the alternator. There is

also a RJ-45 jack and plugs

for the alternator shunt wiring

and red and green indicator

lights used for trouble-

shooting.

3) The Battery Shunt: Dual

500 A, 50 mV shunt used to

measure current flowing in or

out of the batteries.

5) The Alternator Shunt: Single 500 A,

50 mV shunt used to measure current

flowing out of the alternator.

6) Four Conductor Remote Cord: This 25' long

phone cord connects the LINK to the inverter/charger.

This is the smaller of the two cords.

7) Eight Conductor Data Cord: This 25' long cord

connects the Monitor Terminal Board to the Ideal

Regulator Output Module. This is the larger of the

two cords.

Our Customer Service Manager says, "Be a genius—ensure a

successful installation by following our wire-by-wire instructions

and please do the two progress checks and the final startup test."

Be sure the battery shunt is installed before proceeding.

MONITOR BOARD INSTALLATION & WIRING

MOUNTING THE MONITOR TERMINAL BOARD

The Monitor Terminal board should be secured behind or adjacent to the meter. It

should be accessible and easy to see during hookup. The meter comes standard with an

18" ribbon cable.

Wiring is simplified by using our custom multiple conductor twisted pair cable

available from your dealer. See LINK 2000 manual. If you supply your own cable we

recommend 16 AWG. Larger wire is okay but not necessary. Do not use larger than #14

AWG, as it will make terminating the wires difficult. Use twisted pairs where specified. Use

the same color scheme as on the schematic to facilitate troubleshooting if required.

Begin hooking up from the bottom (terminal #1 ) of the terminal strip toward

the top.

These two cords are not interchangeable.

i4.40

12

TERMINAL #10

YELLOW WIRE (B2SHB), is connected to the SMALL SCREW ON THE

BATTERY SIDE of the Battery #2 shunt (B2SHB). The TERMINAL #10 YELLOW

WIRE and TERMINAL #9 BROWN WIRE should be a twisted pair.

PROGRESS CHECK #2

Now it is time to check the battery current function. Plug the meter's ribbon cable into the

Monitor Terminal Board and/or insert the fuses. Turn off all DC loads and charging sources.

With everything off select Battery #1 or #2 Amps—the LINK 2000-R should read 0.0,

-0.0, or no more than -0.1 A. (The meter uses less than 0.1 A.) If there is a larger current

draw it normally means that not all the DC loads are turned off. There may be an alarm

system, a clock, or other instrumentation that is left on all the time intentionally. That is

okay as long as you find each load and decide that it is an acceptable continuous current

draw. Once your base-line current is known, remember it. If you cannot always turn off loads

and reach the same number of amps you should find out why. Turn on various loads and

make sure there is a minus sign in front of the display which indicates discharge. If the

number has no minus sign and there are no charging sources on, it means that the battery

shunt sense leads are reversed. If you have a problem call your dealer or Xantrex

Technology Inc. The wiring is now complete and the battery monitoring functions of the

meter now are fully operational.

The battery monitoring and inverter/charger functions of the LINK 2000-R may be

operated independently of the alternator regulator functions. Simply unplug the 8 conductor

data cord (described in the next section) between the Monitor Terminal Board and the Ideal

Regulator Output Module to disable the regulator. The alternator will freewheel harmlessly.

IDEAL REGULATOR OUTPUT MODULE WIRING

MOUNTING THE OUTPUT MODULE

The Ideal Regulator Output Module may be located anywhere convenient to the

alternator that is not subject to salt or fresh water spray. The components in this module

have been coated to resist corrosion but are not immune to, nor warranted against, abuse.

This module has on it the FET (field effect transistor) that actually does the work of

supplying power to the alternator field. While the reliability of this module is very high

it also does all of the real work. The system has been designed with on-site repairability

in mind, a spare Output Module or a standby regulator should be considered for long-

distance cruising.

The harness that is supplied with this module is a standard alternator harness. It

is keyed so that it cannot be improperly plugged into the module. The colors mentioned

below correspond to the color code of the wiring harness. There is also a 25-foot 8

conductor data cord supplied to interconnect the Monitor Terminal Board and the Ideal

Regulator Output Module. The following discusses each of the wires connected to the

Ideal Regulator Output Module beginning from the left side of the module.