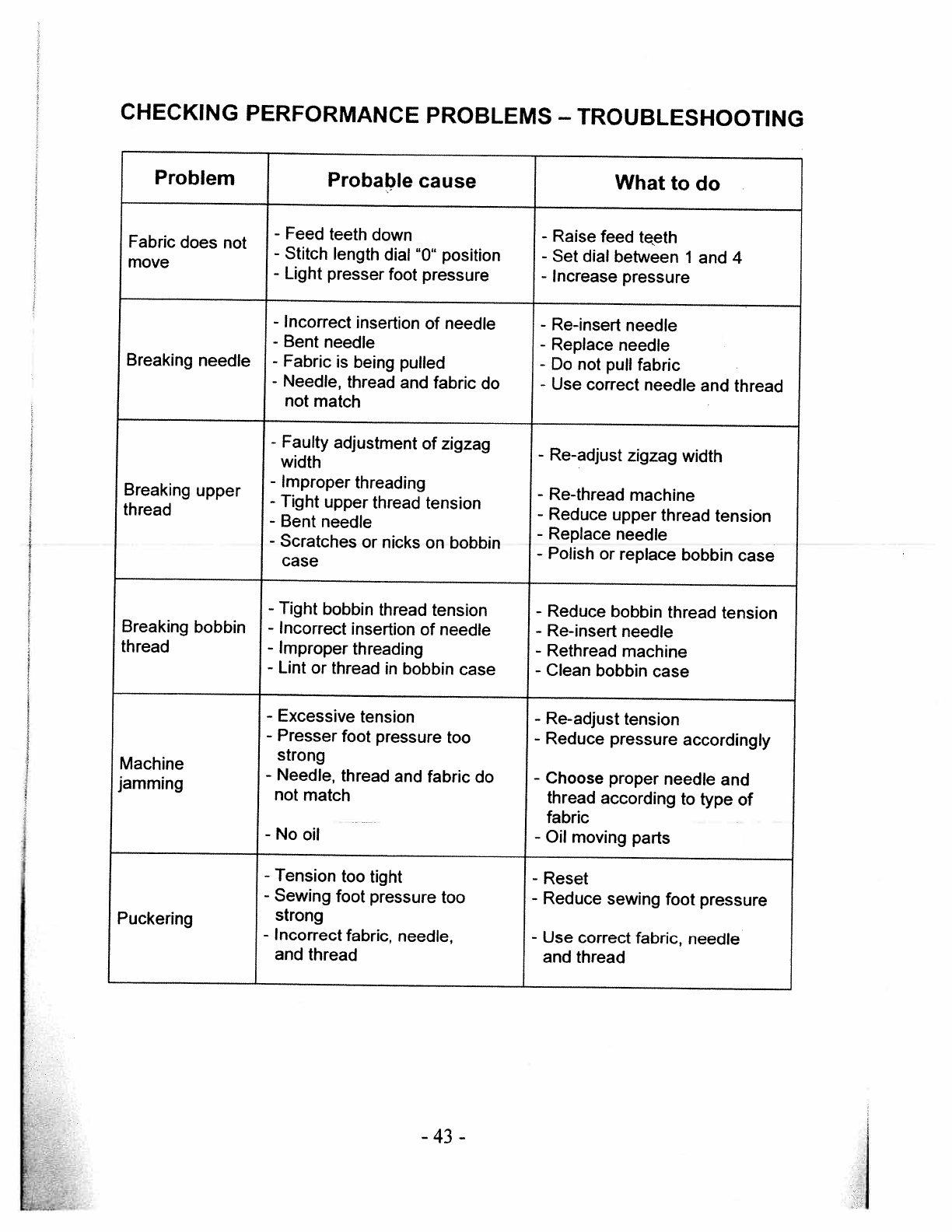

CHECKING

PERFORMANCE

PROBLEMS

-

TROUBLESHOOTING

Problem

Probable

cause

What

to

do

-

Feed

teeth

down

-

Raise

feed

teeth

Fabric

does

not

-

Stitch

length

dial

“0”

position

-

Set

dial

between

1

and

4

move

-

Light

presser

foot

pressure

-

Increase

pressure

-

Incorrect

insertion

of

needle

-

Re-insert

needle

-

Bent

needle

-

Replace

needle

Breaking

needle

-

Fabric

is

being

pulled

-

Do

not

pull

fabric

-

Needle,

thread

and

fabric

do

-

Use

correct

needle

and

thread

not

match

-

Faulty

adjustment

of

zigzag

width

-

Re-adjust

zigzag

width

Breaking

upper

-

Improper

threading

-

Re-thread

machine

thread

-

Tight

upper

thread

tension

-

Reduce

upper

thread

tension

-

Bent

needle

-

Scratches

or

nicks

on

bobbin

-

Replace

needle

-

Polish

or

replace

bobbin

case

case

-

Tight

bobbin

thread

tension

-

Reduce

bobbin

thread

tension

Breaking

bobbin

-

Incorrect

insertion

of

needle

-

Re-insert

needle

thread

-

Improper

threading

-

Rethread

machine

-

Lint

or

thread

in

bobbin

case

-

Clean

bobbin

case

-

Excessive

tension

-

Re-adjust

tension

-

Presser

foot

pressure

too

-

Reduce

pressure

accordingly

Machine

strong

-

Needle,

thread

and

fabric

do

-

Choose

proper

needle

and

jamming

not

match

thread

according

to

type

of

fabric

-

No

oil

-

Oil

moving

parts

-

Tension

too

tight

-

Reset

-

Sewing

foot

pressure

too

-

Reduce

sewing

foot

pressure

Puckering

strong

-

Incorrect

fabric,

needle,

-

Use

correct

fabric,

needle

and

thread

and

thread