20

MAINTENANCE OF YOUR WATER HEATER

Draining and Flushing

It is recommended that the tank be drained and flushed

every 6 months to remove sediment which may build up

during operation. The water heater should be drained if

being shut down during freezing temperatures. To drain the

tank, perform the following steps:

1. Turn off the gas to the water heater at the manual gas

shut-off valve.

2. Close the cold water inlet valve.

3. Open a nearby hot water faucet.

4. Connect a hose to the drain valve and terminate it to an

adequate drain.

NOTE: The drain hose should be rated for at least 200°F.

If the drain hose does not have this rating, open the cold

water inlet valve and a nearby hot faucet until the water is

no longer hot.

5. Open the water heater drain valve and allow all the

water to drain from the tank. Flush the tank with water

as needed to remove sediment.

6. Close the drain valve, refill the tank, and restart the

heater as directed under “Operating Your Water

Heater”.

If the water heater is going to be shut down for an extended

period, the drain valve should be left open.

IMPORTANT: Condensation may occur when refilling the

tank and should not be confused with a tank leak.

Routine Preventive

Maintenance

At least annually, a visual inspection should be made of

the venting and air supply system, piping systems, main

burner, pilot burner, and flame-trap. Check the water heater

for the following:

• Obstructions, damage, or deterioration in the venting

system. Make sure the ventilation and combustion air

supplies are not obstructed.

• Build up of soot and carbon on the main burner and

pilot burner. Check for a soft blue flame.

• Leaking or damaged water and gas piping.

• Presence of flammable or corrosive materials in the

installation area.

• Presence of combustible materials near the water

heater.

• After servicing this water heater, check to make sure it

is working properly. (See Operating Your Water Heater

section of this manual.)

IMPORTANT: If you lack the necessary skills required to

properly perform this visual inspection, you should not

proceed, but get help from a qualified person.

Temperature and Pressure

Relief Valve

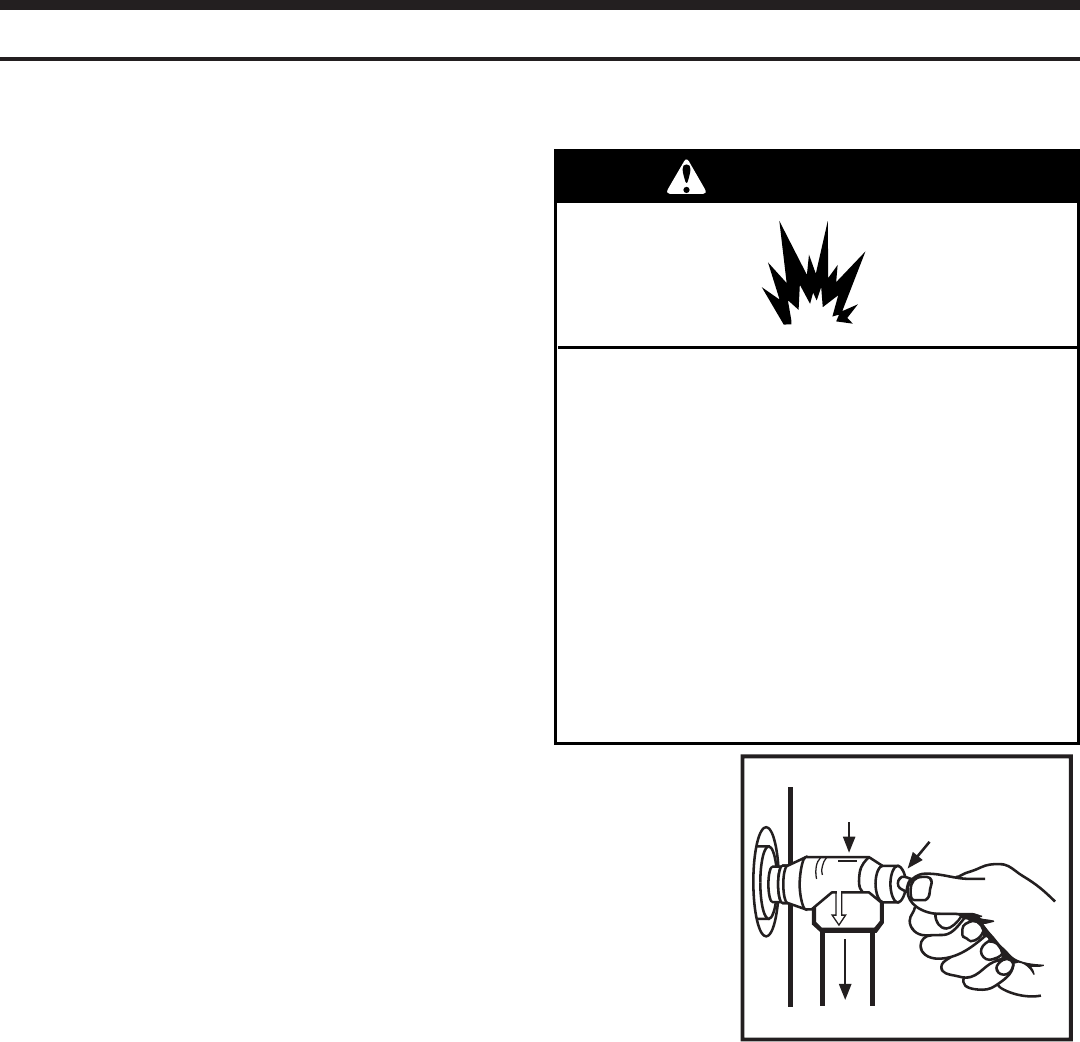

Manually operate

the temperature

and pressure relief

valve at least once

a year to make

sure it is working

properly. To prevent

water damage,

the valve must be

properly connected

to a discharge line

which terminates

at an adequate

drain. Standing clear of the outlet (discharged water may

be hot), slowly lift and release the lever handle on the

temperature and pressure relief valve to allow the valve to

operate freely and return to its closed position. If the valve

fails to completely reset and continues to release water,

immediately shut off the manual gas control valve and the

cold water inlet valve and call a qualified person.

Figure 21

Temperature and Pressure

Relief Valve

Manual Relief

Valve

Discharge line to drain

Explosion Hazard

If the temperature and pressure relief valve

is dripping or leaking, have a qualified

person replace it.

Examples of a qualified person include:

licensed plumbers, authorized gas company

personnel, and authorized service

personnel.

Do not plug valve.

Do not remove valve.

Failure to follow these instructions can

result in death, or explosion.

WARNING