Page 8 6104BAFG R06

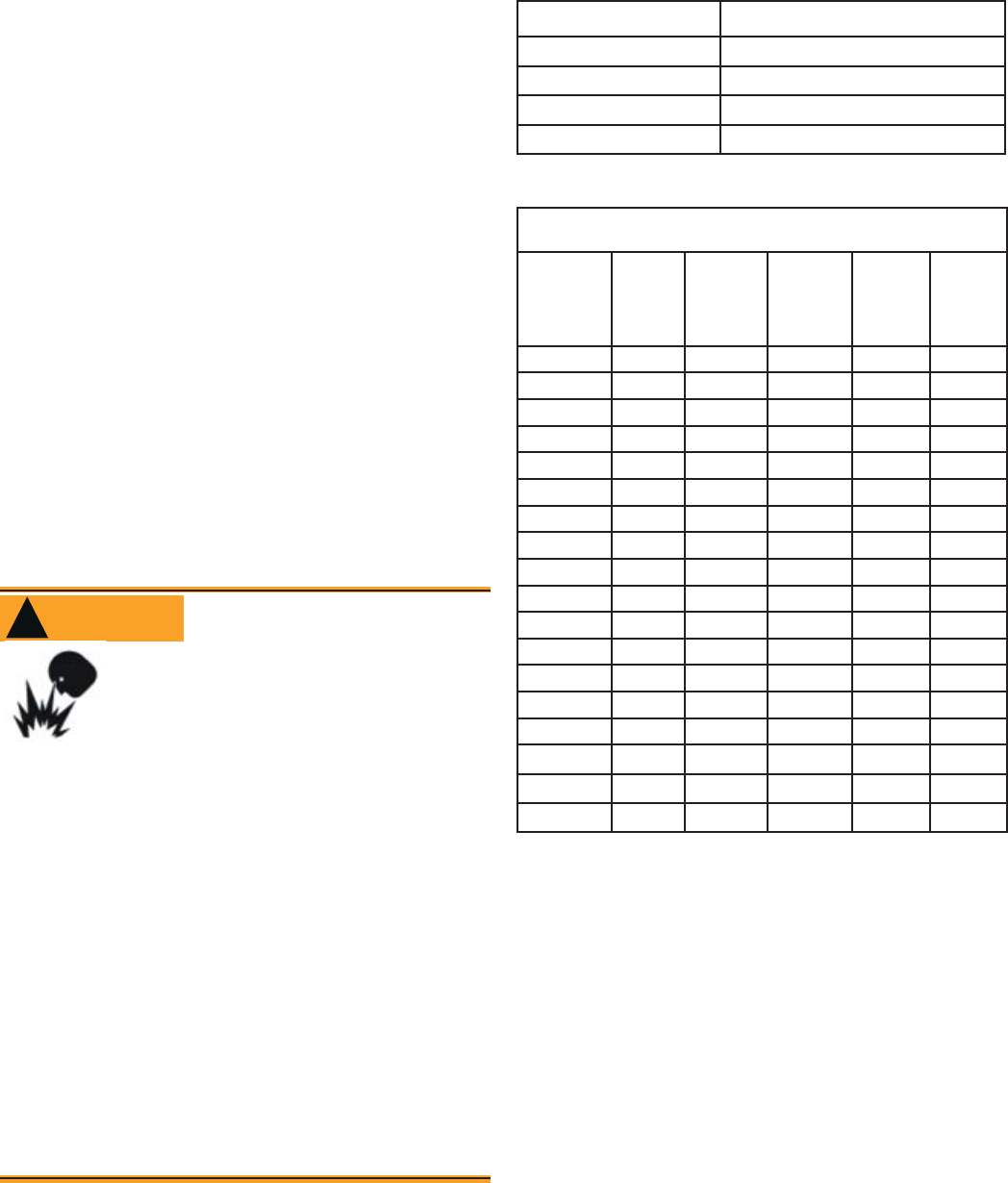

Table 4. AFG Reduced Firing Rates (with

LFRB)

Burner head type Low Firing Rate Baffl e installed

F0 up to 0.65 gph

F3 or L1 up to 0.85 gph

F4 or F6 up to 0.90 gph

V1 up to 1.00 gph

Prepare the Burner

Low Firing Rate Baff e

The AFG Low Firing Rate Baffl e (LFRB) reduces

the air fl ow and pressure. The LFRB is sometimes

used for fi ring rates under 1.00 gph as listed in

Table 4. Refer to the appliance manufacturer’s in-

structions. Do not omit the LFRB when specifi ed.

Omitting the baffl e when specifi ed or installing the

baffl e when not specifi ed could result in impaired

burner performance.

Burner fuel unit

Verify that the burner fuel unit is compatible with

the oil supply system. For more details, refer to

the pump manufacturer’s instructions provided

with the burner.

Attach air tube (if not already installed)

If using a fl ange and gasket, slide them onto the air

tube. Then attach the air tube to the burner chassis

using the four sheet metal screws provided. Refer

to Figure 4 for details.

y

Use only nozzles having the brand, fl ow rate (gph), spray

angle and pattern specifi ed by the appliance manufac-

turer.

Follow the appliance manufacturer’s specifi cations for

the required pump outlet pressure for the nozzle, since

this affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates

at 100 psig.

When pump pressures are higher than 100 psig,

the actual nozzle fl ow rate will be greater than

the gph stamped on the nozzle body. (Example:

A 1.00 gph nozzle at 140 psig = 1.18 gph)

Securely tighten the nozzle (90 torque inch pounds). For

typical nozzle fl ow rates at various pressures refer to

Table 5.

y

y

Incorrect nozzles and fl ow rates

could result in impaired combus-

tion, under-fi ring, over-fi ring, soot-

ing, puff-back of hot gases, smoke

WARNING

!

Correct Nozzle and Flow

Rate Required

and potential fi re or asphyxiation hazards.

Nozzle and Pump Pressure

Install burner nozzle (if not already in-

stalled)

Remove the plastic plug protecting the nozzle

adapter threads

Place a 3/4” open-end wrench on the nozzle

adapter. Insert the nozzle into the adapter and fi n-

ger tighten. Finish tightening with a 5/8” open-end

wrench. Use care to avoid bending the burner head

support legs or electrodes. If you remove the head

to replace the nozzle (type “L1”/“L2” or “V1” heads),

carefully reconnect the head to the nozzle adapter,

making sure that the head support makes contact

with the nozzle adapter shoulder. Refer to Figure

5 or 6.

1.

2.

Nozzle f ow rate U. S. gallons per hour of No. 2 fuel oil when

pump pressure (psig) is:

Nozzle

size

(rated at

100 psig)

125

psi

140 psi 150 psi 175 psi 200 psi

0.40 0.45 0.47 0.49 0.53 0.56

0.50 0.56 0.59 0.61 0.66 0.71

0.60 0.67 0.71 0.74 0.79 0.85

0.65 0.73 0.77 0.80 0.86 0.92

0.75 0.84 0.89 0.92 0.99 1.06

0.85 0.95 1.01 1.04 1.13 1.20

0.90 1.01 1.07 1.10 1.19 1.27

1.00 1.12 1.18 1.23 1.32 1.41

1.10 1.23 1.30 1.35 1.46 1.56

1.20 1.34 1.42 1.47 1.59 1.70

1.25 1.39 1.48 1.53 1.65 1.77

1.35 1.51 1.60 1.65 1.79 1.91

1.50 1.68 1.77 1.84 1.98 2.12

1.65 1.84 1.95 2.02 2.18 2.33

1.75 1.96 2.07 2.14 2.32 2.48

2.00 2.24 2.37 2.45 2.65 2.83

2.25 2.52 2.66 2.76 2.98 -

2.50 2.80 2.96 - - -

Table 5. Nozzle Flow Rate by Size

Inspect/Prepare Installation Site