6104BAFG R06 Page 7

Inspect/Prepare Installation Site

Combustion air supply

The burner cannot properly burn the fuel if it is not

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the

NFPA 31 and CSA-B139 regarding providing ad-

equate air for combustion and ventilation.

y

y

Failure to provide adequate air supply could

seriously affect the burner performance and re-

sult in damage to the equipment, asphyxiation,

explosion or fi re hazards.

WARNING

!

Adequate Combustion

and Ventilation Air Supply

Required

Do not attempt to install outside air piping to

the burner without using the outside air kit and

instructions.

y

Failure to comply could result in impaired com-

bustion, appliance soot-up, puffback of smoke,

and fi re or asphyxiation hazards.

Follow the Outside Air Kit

Instructions Exactly

WARNING

!

When retrofi tting appliances that have unlined

stainless steel combustion chambers, protect

the chamber by lining the inside surfaces with a

ceramic fi ber blanket, such as a wet-pac or other

suitable refractory material.

Some steel chambers may not require liners

because the appliance was designed and tested

for use with fl ame retention burners. Refer to the

manufacturer’s instructions.

y

y

Failure to comply could result in damage to the

heating equipment and result in fi re or asphyxi-

ation hazards.

WARNING

!

Protect Steel Combustion

Chamber From Burnout

Appliance located in confi ned space

The confi ned space should have two (2) permanent

openings: one near the top of the enclosure and

one near the bottom of the enclosure. Each open-

ing shall have a free area of not less than (1) one

square inch per 1,000 BTU’s per hour of the total

input rating of all appliances within the enclosure.

The openings shall have free access to the build-

ing interior, which should have adequate infi ltration

from the outside.

Exhaust fans and other air-using devices

Size air openings large enough to allow for all air-

using devices in addition to the minimum area re-

quired for combustion air. If there is any possibility

of the equipment room developing negative pres-

sure (because of exhaust fans or clothes dryers, for

example), either pipe combustion air directly to the

burner or provide a sealed enclosure for the burner

and supply it with its own combustion air supply.

Direct air supply and sidewall venting

Some AFG burners are equipped with combus-

tion air boots to allow use of outside air for com-

bustion.

When sidewall venting appliances, carefully fol-

low appliance and power venter instructions for

installation and wiring.

y

y

Outside air kit applications

Refer to separate instruction sheet supplied with

AF/AFG outside air kit for installation. This optional

kit allows combustion air to be piped directly to the

burner (Beckett part number 51747).

Clearances to burner and appliance

Provide space around burner and appliance for

easy service and maintenance.

Check minimum clearances against those shown

by the appliance manufacturer and by applicable

building codes.

y

y

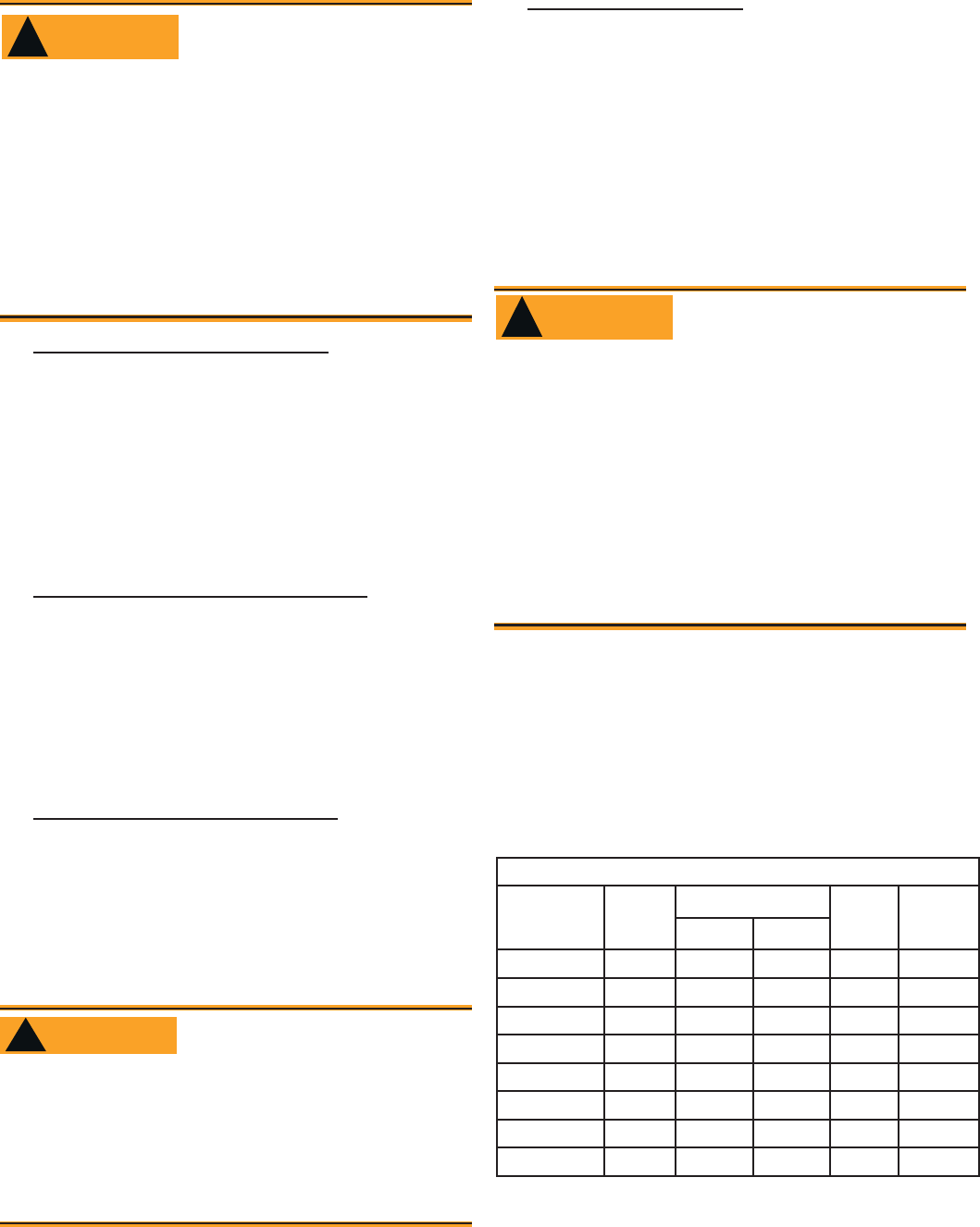

Combustion chamber — Burner retrof t-

ting

Verify that the appliance combustion chamber pro-

vides at least the minimum dimensions given in

Table 3.

Chamber Dimensions (inches)

Firing Rate

(GPH)

Round

I.D.

Rectangular Height Floor to

nozzle

Width Length

0.50 8 7 8 12 5-6

0.75 9 8 9 12 5-6

1.00 10 9 10 12.5 5-6

1.25 11 10 11 12.5 5-6

1.50 12 11 12 13 6-7

2.00 14 12 15 13.5 6-7

2.50 16 13 17 14 7-8

3.00 18 14 18 15 7-8

Table 3. Chamber Dimensions