Part Number 550-110-639/0703

6

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Installation

(continued)

1

Figure 3

Hydrostatic pressure test

Pressure test before attaching gas piping or electrical supply.

1. Plug any necessary boiler tappings or openings.

2. Do not use gauge supplied with boiler for pressure testing. Install gauge with

appropriate range.

3. Fill boiler with water. Vent all air. Test steam boilers between 45 - 55 psi and

water boilers at 1-1/2 times working pressure.

Do not leave boiler unattended. A cold water fill could expand

and cause excessive pressure, resulting in severe personal injury,

death or substantial property damage.

4. Check for maintained gauge pressure and leaks. Repair if found.

Leaks must be repaired at once. Failure to do so can cause boiler

damage, resulting in substantial property damage.

Do not use petroleum-based sealing compounds in boiler system.

Severe damage to boiler will result, causing substantial property

damage.

5. Drain boiler and repair leaks if found.

6. Retest boiler after repairing leaks.

7. Remove plugs from any tappings that will be used for controls and accessories.

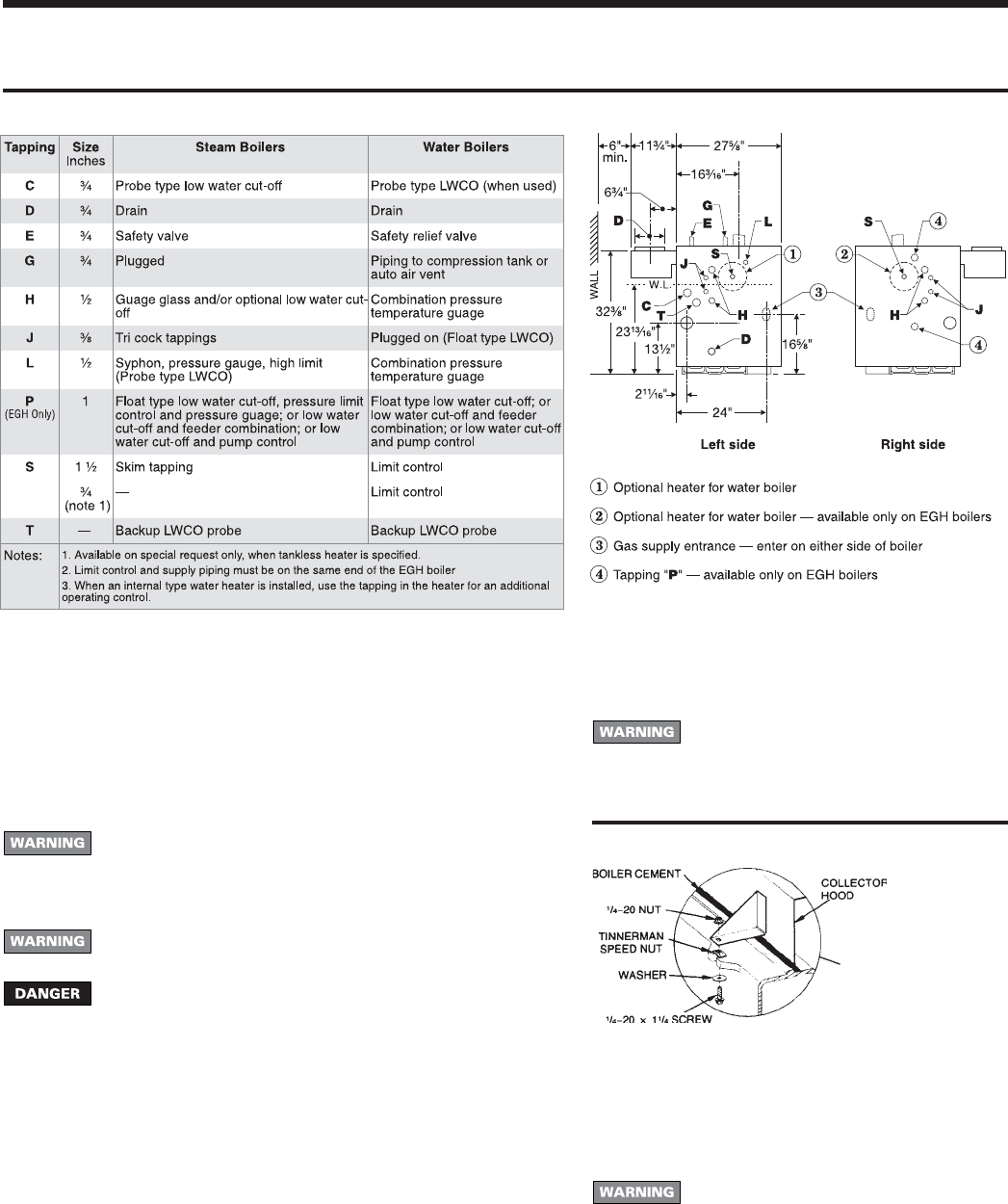

Refer to control tapping table and Figure 3.

8. On initial start-up check for leaks in the system piping. If found, repair at

once.

Installation of flue collector hood

(Factory installed on PEG boilers)

Set flue collector hood on boiler as shown in Figure 4.

Use boiler cement furnished to provide gas-tight seal.

Failure to maintain gas-tight seal can cause

flue gas spillage and carbon monoxide

emissions, resulting in severe personal

injury or death.

Installation of front and back base

panels (Factory installed on PEG boilers)

See Figure 5 for installation. Fasten front (6 1/8 inch) and

back 7 5/16 inch) base panels to sections. Seal with boiler

cement along top of insulation panels.

Failure to maintain gas-tight seal can cause

flue gas spillage and carbon monoxide

emissions, resulting in severe personal

injury or death.

Figure 4 Flue collector hood