Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts

You May Need. You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

10

Tools Needed:

FAILURE TO SECURELY

ATTACH A SUITABLE

MOUNTING PAD TO STRUCTURALLY SOUND

FRAMING COULD CAUSE SPRINGS TO VIOLENTLY

PULL MOUNTING PAD FROM WALL, RESULTING

IN SEVERE OR FATAL INJURY.

If you just removed your existing door or you are installing a new

door, complete all steps in PREPARING THE OPENING.

For detailed technical information regarding the opening

preparation, refer to the DASMA Technical Data Sheet TDS #161

“Connecting Garage Door Jambs to Building Framing” at www.

dasma.com.

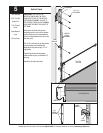

The inside of your garage door opening should be framed with

wood jambs and header. It is recommended that 2” x 6” lumber

be used. The jambs must be plumb and the header level. The

jambs should extend a minimum of 14” (356 mm) above the top

of the opening for Torsion

springs applications. For low headroom

applications, the jambs should extend to the ceiling height.

Minimum side clearance required, from the opening to the wall, is

3-1/2” (89 mm).

IMPORTANT: CLOSELY INSPECT JAMBS, HEADER AND MOUNTING

SURFACE. ANY WOOD FOUND NOT TO BE SOUND, MUST BE

REPLACED.

The jambs and header must be securely fastened to sound framing

members. Do not place jambs and header over drywall, paneling,

etc. Heads of fasteners must be flush or below jamb and header

surface, so they do not interfere with installation or operation of

new door.

Torsion

springs applications, a suitable mounting surface must be

firmly attached to the wall, above the header at the center of the

opening.

The mounting surface must be 2” x 6” lumber minimum (Select

southern yellow pine lumber. Do not use lumber marked as spruce-

pine-fur or SPF).

The mounting surface must be securely attached to block or

concrete wall with four (4) 3/8” masonry anchors or four

(4) 5/16” x 4” lag screws for a wood structure.

NOTE: Drill a 3/16” pilot hole in the mounting surface to avoid

splitting the lumber. Do not attach the mounting surface with

nails.

WEATHER SEAL / DOOR STOP: Cut weather seal or door stop (may

not be included) to fit the jambs and header.

Align the edge of the weather seal or door stop an 1/8” to 1/4”

inside the edge of the opening. Temporarily nail approximately

12” to 18” apart, the weather seal apart. or door stop to the

jambs to keep the bottom section from falling out of the opening

during installation.

NOTE: Do not permanently attach weather seal or door stop to the

jambs at this time. Permanent installation will be done in Step 19.

HEADROOM REQUIREMENT: Headroom is defined as the space

needed above the top of the door for tracks, springs, etc. to allow

the door to open properly. If the door is to be motor operated, 2-1/2”

(64 mm) of additional headroom is required.

BACKROOM REQUIREMENT: Backroom is defined as the distance

needed from the opening back into the garage to allow the door

to open fully.

Preparing the Opening

WARNING

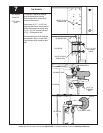

TRACK TYPE TorqueMaster

®

14” Radius track 12”

P5

Recommended

tools from

page 5

HEADROOM REQUIREMENT

BACKROOM REQUIREMENT

WEATHER SEAL

HEADROOM

BACKROOM

DOOR

WIDTH

DOOR HEIGHT

LEVEL HEADER

PLUMB JAMBS

SUITABLE MOUNTING

SURFACE 2” X 6”

LUMBER MINIMUM

HEADER

JAMB

JAMB

FULLY ADJUSTABLE TRACK

JAMB

1/8” TO 1/4”

WEATHER

SEAL

DOOR

STOP

DOOR

STOP

DOOR

SECTION

DOOR

SECTION

JAMB

JAMB

1/8” TO 1/4”

HEADER BOARD

2” X 6” LUMBER

RECOMMENDED

DOOR HEIGHT TRACK MANUAL LIFT

MOTOR

OPERATED

6’6” 14” Radius 90” 125”

7’0” 14” Radius 96” 125”

8’0” 14” Radius 108” 137”