14

IMPORTANT: The electronic S8600 Control Module cannot be repaired. If troubleshooting procedure indicates a malfunction in

the S8600 the S8600 Control Module must be replaced. Intermittent pilot systems should be serviced only by

trained and experienced personnel.

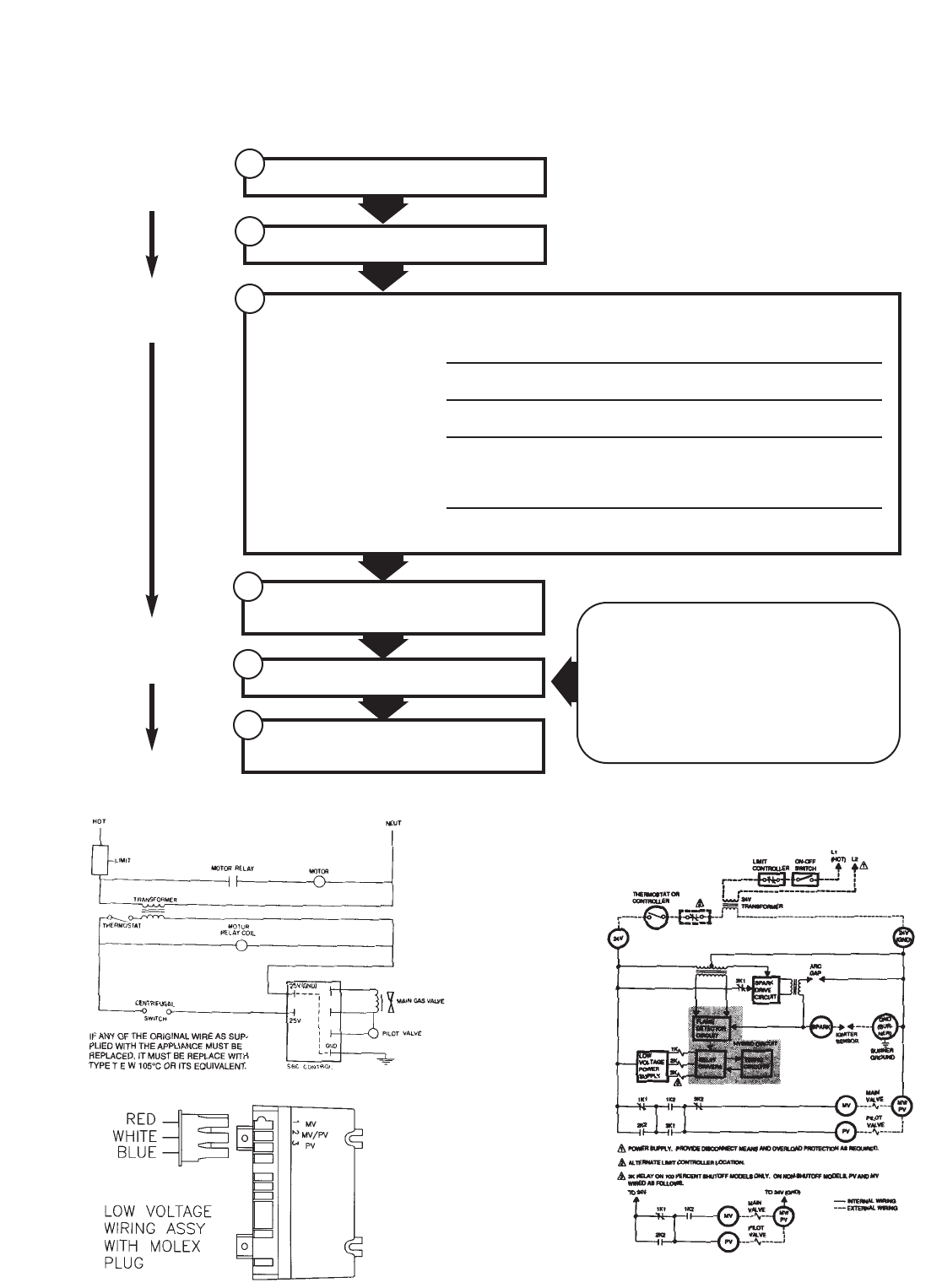

SEQUENCE OF OPERATION

1

THERMOSTAT (CONTROLLER)

CALLS FOR HEAT

2

SPARK GENERATOR

powered by First Valve (pilot) operator opens

4

FLAME CURRENT SENSED

• Spark generator off

• Second valve operator (main) opens.

4

MAIN BURNER OPERATION

Module monitors pilot flame current.

4

THERMOSTAT (CONTROLLED)

SATISFIED

Valves close, pilot and main burners are off.

3

PILOT BURNER OPERATION

Pilot burner lights.

Module senses

flame current.

OR

Pilot burner does not light

Module Response

S8600A,F Ignition spark continues, pilot valve remains

S8610A, F open until system is reset

S8600B, H After 15 or 90 sec. a system

S8610B, H lock outs; must be manually reset

S8600M After on sec. a system shuts off; after 5 minutes

min. (6 minutes nom.), module restarts trial for

ignition; ignition trial, shutoff, wait sequence

repeats until pilot lights or call for heat ends.

a Shutoff/lockout timing is stamped on module

POWER INTERRUPTION

System shuts off, restarts when power is

restored.

PILOT FLAME FAILURE

Mail valve closes.

Module starts trial for ignition.

START

STAGE 1

TRIAL FOR

IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

WIRING DIAGRAM LADDER FORM

WIRING DIAGRAM HONEYWELL EP SYSTEM

S86