11

All adjustments below must be made with the following instructions:

1. Draft Gauge 3. CO Tester

2. O

2

or CO

2

Analyzer 4. Water Column Gauge

After the burner has been in operation for 10 minutes and if a neutral pressure point adjuster was installed, proceed as

follows. Start from the wide open position and gradually close the neutral pressure point adjustment. Crack observation door

about 1/8 inch (3.175mm). Then by holding match flame along opening, the neutral pressure point can be determined. The

flame should be drawn in below the center of the door and it should be blown outward above the center. In other words, the

pressure inside the combustion chamber should be above atmospheric pressure above the burner flame and below atmospheric

pressure below the burner flame. The pressure should be neutral at the center. Closing the adjuster lowers the neutral

pressure point and opening the adjuster raises the neutral pressure point.

Once the neutral pressure point has been adjusted, the combination air shutter should be adjusted so that the percent CO

2

test must be made at the inlet side of the draft hood. If the CO

2

reading is not within the recommended limits, then the

combustion air shutter should be re-adjusted and then the neutral pressure point be rechecked and reset if necessary.

IT IS ESSENTIAL TO MAKE CERTAIN THAT THE PRODUCTS OF COMBUSTION DO NOT CONTAIN CARBON

MONOXIDE, CO. It is possible to have flame impingement on cold surfaces with resultant CO even if CO

2

and O

2

are within

acceptable limits. The flue gas sample is taken through the same hole used for the CO

2

test. CO test instrument must be used

for this test.

The most common causes of CO are flame impingement on cool surface and insufficient primary air, both of which could be

caused by over firing. The only answer is to reduce the firing rate or increase the primary air.

Combustion efficiency is determined by the percent CO

2

and the temperature of the flue gases. These two measurements

are taken on the inlet side of the draft hood. Combustion efficiency and stack loss calculators provide slide rule convenience for

correlating CO

2

and stack temperature readings. These calculators are available from several manufactures of combustion test

equipment.

IMPORTANT

DRAFT - When installing Wayne power gas burners in oil fired boilers a minimum negative draft of .02” (4.982 Pa) w.c. over

fire must be maintained.

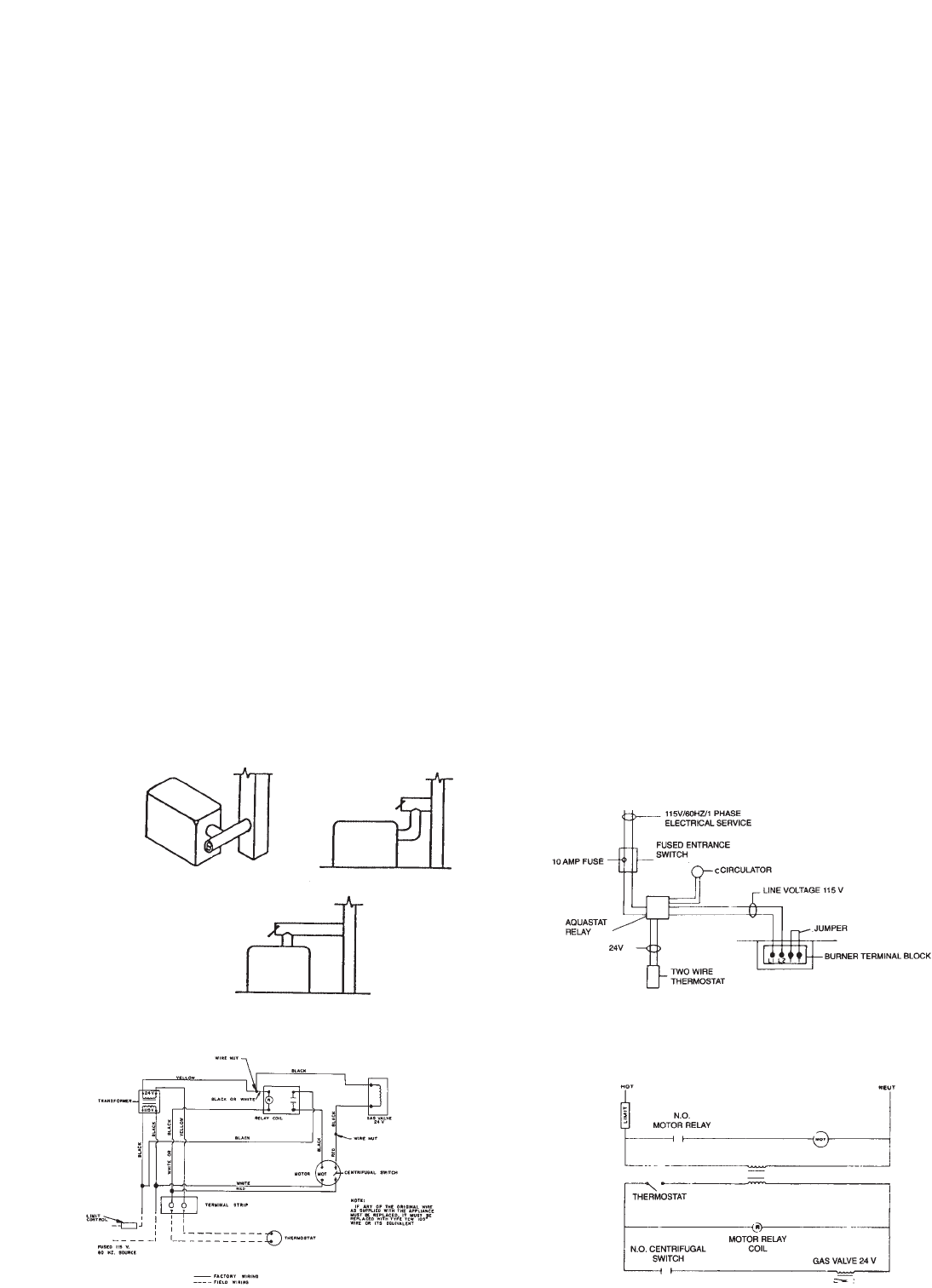

Refer to your local gas company and codes for assistance.

For gad fired equipment requiring a double acting barometric the preferred location of the barometric draft control is part of

the bullhead tee shown in figures A, B OR C. During normal operation, flue gases make a right angle turn behind the control,

but do not infringe upon it. Should a downdraft occur, air flowing n the opposite direction strikes the control directly, causing it to

open outwardly and vents the air into the room with a minimum of resistance. Entrained products of combustion are thus

provided grater relief.

BEST LOCATIONS FOR GAS

WIRING DIAGRAM LADDER FORM

WIRING DIAGRAM FOR GAS BURNER WITH STANDING PILOT

WIRING DIAGRAM LADDER FORM

FIG. A FIG. B

FIG. C

FIGURE 12

FIGURE 13