18-CD19D6-32 11

Installer’s Guide

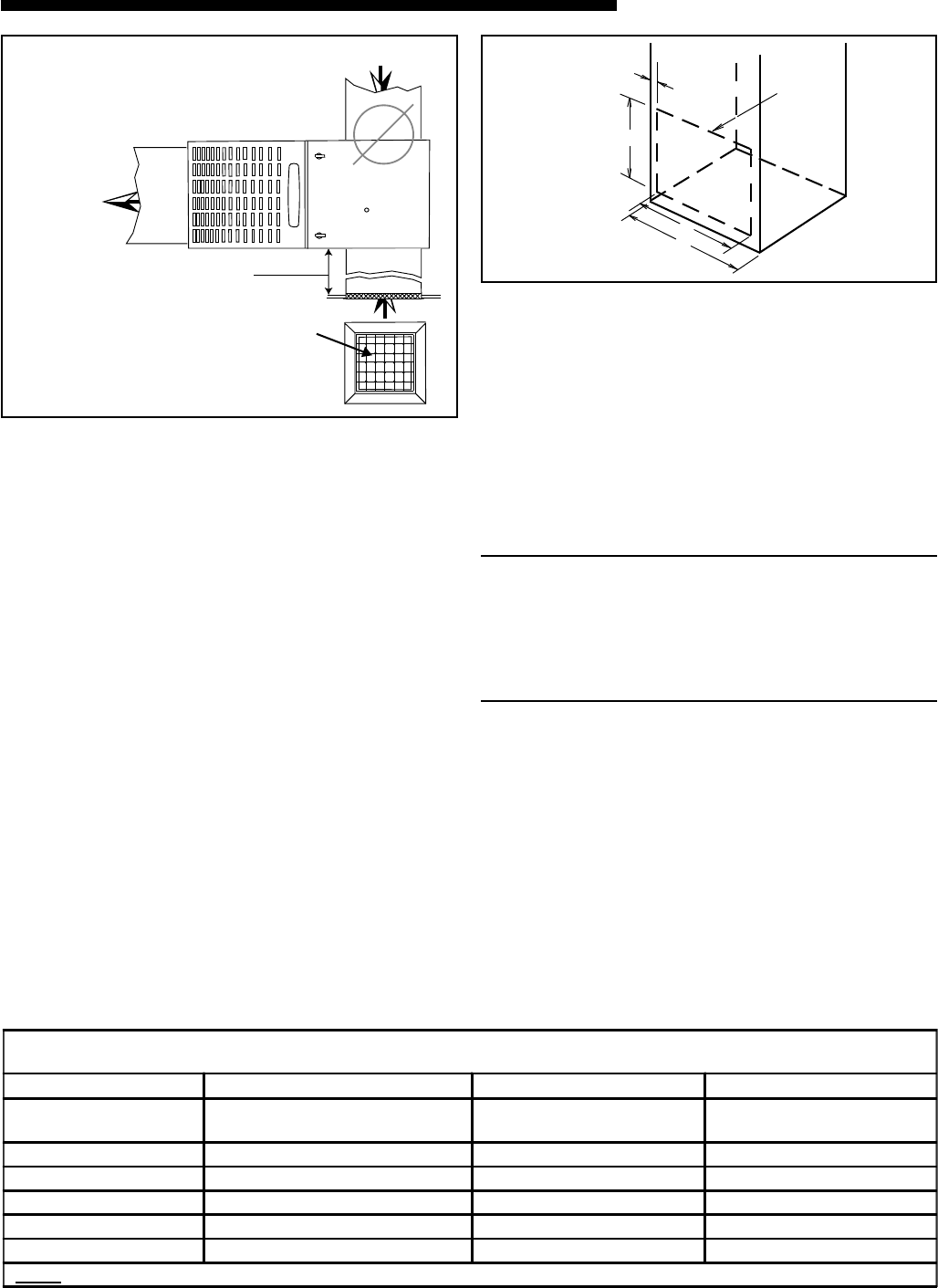

FILTER

REMOVE FILTER FROM UPFLOW

FURNACE WHEN RETURN DUCT IS

ATTACHED TO FURNACE TOP SIDE

(HORIZONTAL LEFT OR RIGHT

APPLICATIONS) AS SHOWN.

Close coupled (less than 36")

return (filter directly beneath bottom

side return) not recommended due to

noise considerations. If used, securely

attach 1/2" mesh metal hardware cloth

protective screen to the inside bottom of

filter grill.

q

*

SEE OUTLINE DRAWING

w

LOCATING

NOTCHES

PROVIDED

FOR SIDE

RETURN

CUTOUT

*

*

*

*

CUT OUT

FOR

SIDE

FILTER

FRONT

of Furnace

7. Connect the duct work to the furnace. See Outline

Drawing (pages 4&5) for supply and return duct size

and location. Flexible duct connectors are recom-

mended to connect both supply and return air ducts

to the furnace.

If only the front of the furnace is accessible, it is

recommended that both supply and return air

plenums are removable.

8. When replacing a furnace, old duct work should be

cleaned out. Thin cloths should be placed over the

registers and the furnace fan should be run for

10 minutes. Don’t forget to remove the cloths

before you start the furnace.

RETURN AIR FILTERS

(Filter and filter rack are not supplied with unit)

TYPICAL UPFLOW RETURN AIR FILTER INSTALLA-

TIONS

These furnaces require high velocity type air filters.

The optional filters may be located within the furnace

blower compartment for UPFLOW furnaces in either a

BOTTOM or SIDE (left side or right side) return air

inlet. Some optional filters may need to be trimmed for

side or bottom filter use.

NOTE:

On upflow 5 or 6 ton airflow models where the

airflow requirement exceeds 1800 CFM - Models will

require return air openings and filters on: (1) both

sides; or (2) one side and the bottom; or (3) just the

bottom.

The furnace and the blower filter rack installation can

be seen in Figure 13.

The optional furnace filter in the bottom or side con-

figuration can be removed by simply turning the two

latches on the blower door and tilting the door forward.

The filter rails are spring loaded for automatic adjust-

ment to allow standard size, locally obtainable replace-

ment filters. The filter rack itself slides to adjust to the

required width needed for bottom or side return.

MINIMUM CLEARANCE FROM COMBUSTIBLE MATERIALS FOR

UPFLOW/HORIZONTAL AND DOWNFLOW/ HORIZONTAL FURNACES

UNIT LOCATION

FURNACE SURFACE

VERTICAL

CLOSET

HORIZONTAL

CLOSET

HORIZONTAL

ALCOVE / ATTIC

SIDES 0" 1" 0"

BACK 0" 3" 6"

TOP 1" 1" 1"

FRONT 3" 3" 18"

VENT 0" 0" 0"

NOTE

: CLEARANCE REQUIRED AT TOP OF PLENUM IS 1"