28 18-CD19D6-32

Installer’s Guide

NOTE:

Use 1/2" or larger PVC or CPVC pipe and fittings as re-

quired for drain connections (fittings, pipe and solvent

cement not provided).

NOTE:

A corrosion resistant condensate pump must be used

if a pump is required for a specific drain system.

IMPORTANT:

The condensate drain should be installed with provi-

sions to prevent winter freeze-up of the condensate

drain line. Frozen condensate will block drains, result-

ing in furnace shutdown. If the drain line cannot be in-

stalled in a conditioned space, then UL listed heat tape

should be applied as required to prevent freezing (per

manufacturer’s instructions). The heat tape should be

rated at 5 or 6 watts per foot at 120 volts. Self-regulat-

ing (preferred) or thermostatically controlled heat tape

is required.

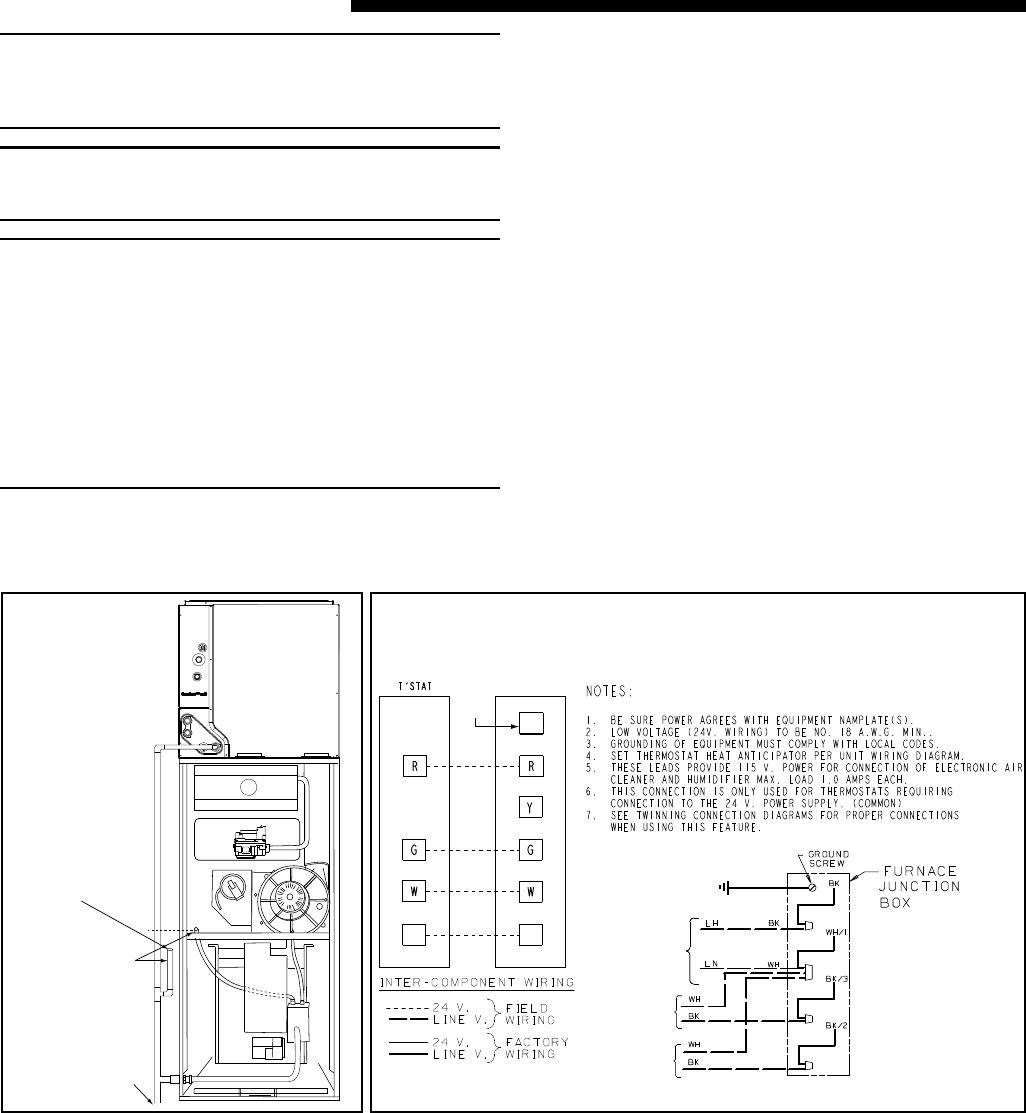

SEE

NOTE 6

From drawing B341437 Rv 1

FURNACE

TWIN

SEE

NOTE 7

B/C

B/C

TO 115 V 1 PH.,

60 HZ., POWER

SUPPLY PER

LOCAL CODES

HUM SEE

NOTE 5

EAC SEE

NOTE 5

FIELD WIRING DIAGRAM FOR 1 STAGE FURNACE

1 STAGE HEATING

USING A 1 STAGE HEATING THERMOSTAT

NO COOLING

Primary drain vent stack

must terminate below

secondary heat exchanger

condensate drain outlet.

To drain opening

If upflow furnace is installed

over a finished ceiling, overflow

from the primary drain vent

stack must flow into an auxillary

drain pan to prevent damage to

the finished ceiling below.

W

Evaporator and furnace condensate drain piping may

be manifolded together as shown in Figure 52. A pri-

mary drain vent stack must be installed and termi-

nated below the outlet of the secondary heat exchanger

drain connection to prevent water from damaging fur-

nace controls if the primary drain outlet plugs up.

Where the furnace is installed above a finished ceiling,

the primary drain vent stack must be installed such

that overflow from the vent stack opening will flow into

an axillary drain pan in order to prevent water damage

to the finished ceiling below.

TWINNING FURNACES

These furnaces may be twinned. Twinning requires that

two furnaces with the same configuration, capacity, and

airflow must be used. They shall have common returns

with equal pressure drops or ducts with equivalent

lengths and sizes. See Field Wiring Diagrams for proper

hookup.