8 MS-SVN015-EN

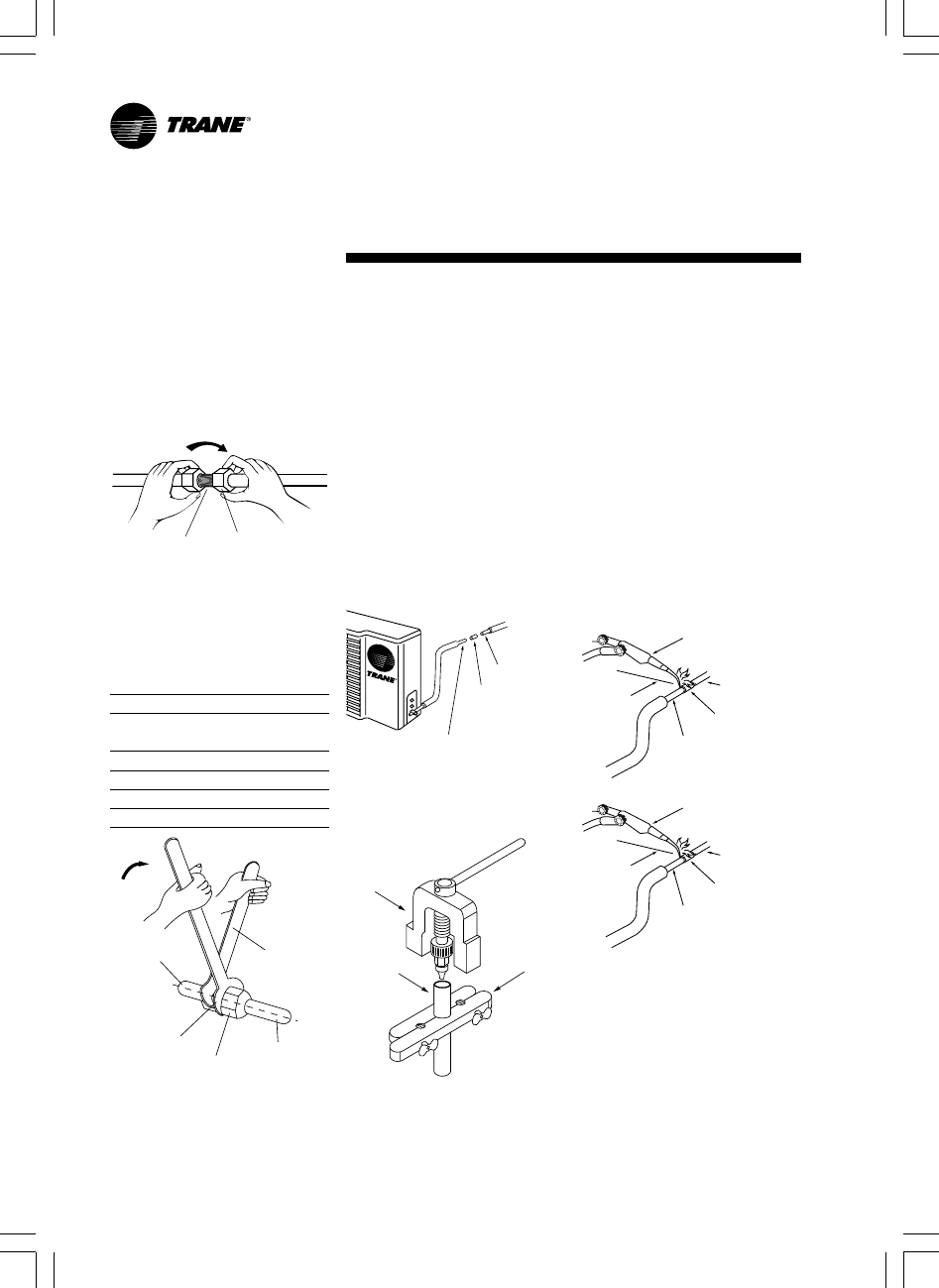

Connection

9. For proper connection, align the

union tube and flare tube straight

with each other, then screw in the

flare nut lightly at first to obtain a

smooth match (Figure 17).

10.

Tighten the flare nut to the

specified tightening torque with

torque wrench and adjustable

wrench (Figure 18).

Flare Nut Tightening Torque

Flare Nut/Piping Size Tightening Torque

kgf, - cm lbf-in

6.35 mm (1/4") dia. 150~200 130~170

9.53 mm (3/8") dia. 350~400 300~340

12.7 mm (1/2") dia. 500~550 430~470

15.88 mm (5/8") dia.600~650 520~570

11. Repeat the process above for the

remaining line.

Connecting the unit with

brazing procedure

(Only for MCX 042-060)

1. Cut the copper tube to the

required length with a tube cutter.

It is recommended to cut approx.

20-30 cm. longer than the tube

length you estimate.

2. Remove burrs at the end of the

copper tube with a tube reamer

(Figure 12).

3. There are 2 ways to connect the

copper tube

- Use a coupling between the

copper tube of indoor unit and

the copper tube used for

installation (Figure 19).

- Expand the copper tube by

using a swaging tool set as in

Figure 20.

4.

Clean internal and external surfaces

of coupling or expanded tube prior

to brazing.

Figure 17

Figure 18

Figure 20

Figure 19

5. Insulate the entire gas line.

6. Do not allow uninsulated liquid

line to come in direct contact

with bare gas line.

7. Precautions should be taken to

avoid heat damage to the

pressure tap valve core during

brazing. It is recommended that

a wet rag be wrapped around the

valve body.

8. It is recommended to use braze

shield, soak pad in water and

place over suction and liquid

lines to protect unit finish.

9. To braze the copper tube, before

brazing a copper tube to a solder

coupling or a copper tube to an

expanded tube, do not forget to

keep them tight as shown in

Figure 21, 22.

10.Use a dry nitrogen purge and

brazing alloy without flux when

brazing the field line to the

copper factory connection. Flow

dry nitrogen into either valve

pressure tap port, through the

tubing and out the other port

while brazing.

11.Braze using accepted good

brazing techniques.

Copper tube of

outdoor unit

Solder coupling

Swaging

tool

Copper

tube

Tube holder

(Clamp)

Union Flare nut

Solder

coupling

C

O

M

M

E

T

3

Figure 21

To rc h

Copper tube

from indoor

unit

Solder rod

Copper tube from

outdoor unit

Solder

coupling

C

O

M

M

E

T

3

Figure 22

To rc h

Copper tube

from indoor

unit

Solder rod

Copper tube from

outdoor unit

Copper tube

of indoor unit

Indoor unit

pipe

Wrench

(adjustable)

Torque

wrench

Flare nut

Connection pipe

Connection of Refrigerant Tubing

MS-SVN015-EN.p65 6/27/07, 11:23 AM8

Black