– 54 –

4. Coil heating control

1) This control function heats the compressor by turning on the stopped compressor instead of a case heater.

It purposes to prevent stagnation of the refrigerant inside of the compressor.

2) As usual, turn on power of the compressor for the specified time before a test run after installation;

otherwise a trouble of the compressor may be caused.

As same as a test run, it is recommended to turn on power of the compressor beforehand when starting

operation after power of the compressor has been interrupted and left as it is for a long time.

3) A judgment for electricity is performed by TD and TO sensors.

If TO sensor is defective, a backup control is automatically performed by TE sensor.

For a case of defective TO sensor, judge it with outdoor LED display.

4) For every model, the power is turned off when TD is 30°C or more.

REQUIREMENT

While heating the coil, the power sound may be heard. However it is not a trouble.

5. Short intermittent operation preventive control

1) For 3 to 10 minutes after operation start, in some cases, the compressor does not stop to protect the

compressor even if receiving the thermostat-OFF signal from indoor.

However it is not abnormal status. (The operation continuance differs according to the operation status.)

2) When the operation stops by the remote controller, the operation does not continue.

6. Current release control

No. of revolutions of the compressor is controlled by AC current value detected by T611 on the outdoor P.C.

board so that the input current of the inverter does not exceed the specified value.

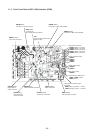

Intermittent power-ON

10 minutes: ON /

5 minutes: OFF

Output

[40W or equivalent]

Continuous power-ON

Output

[40W or equivalent]

No power

(Normal time) (In defective TO sensor)

TO

15˚C

10˚C

8˚C

18˚C

• Power-ON

condition

TD<30˚C

Intermittent power-ON

10 minutes: ON /

5 minutes: OFF

Output

[40W or equivalent]

Continuous power-ON

Output

[40W or equivalent]

No power

TE

18˚C

12˚C

10˚C

20˚C

• Power-ON

condition

TD < 30˚C

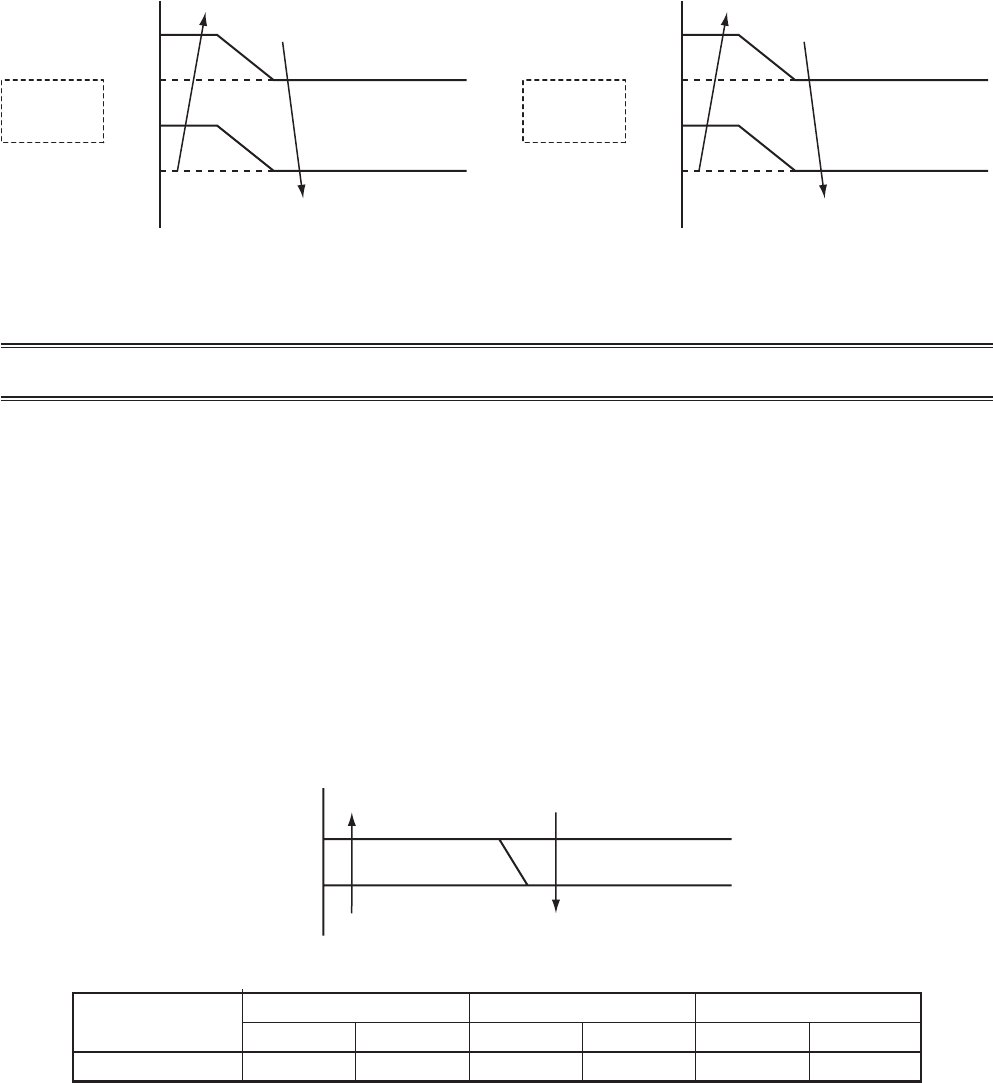

I1–1.0

I1

Current [A]

Normal operation

Frequency down

Hold Hold

Objective model

I1 value [A]

SP110 SP140 SP160

COOL HEAT COOL HEAT COOL HEAT

9.6 15.2 9.6 15.2 9.6 15.2