– 148 –

No.

11

Part name

Compressor

Compressor lead

(Continued)

Remarks

Procedure

2. Mounting of compressor

1) Mount the compressor in the reverse

procedure for removal.

Note)

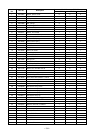

• After replacement of the compressor,

necessarily replace the compressor lead wires.

(Spare parts code: 43160591)

In this time, wind compressor lead around the

ferrite core by 5 times.

Treat the compressor lead wire which was

wound around the ferrite core so that it does

not come to contact with piping.

After replacement of compressor lead as

original, perform piping along the partition

plate with natural tension.

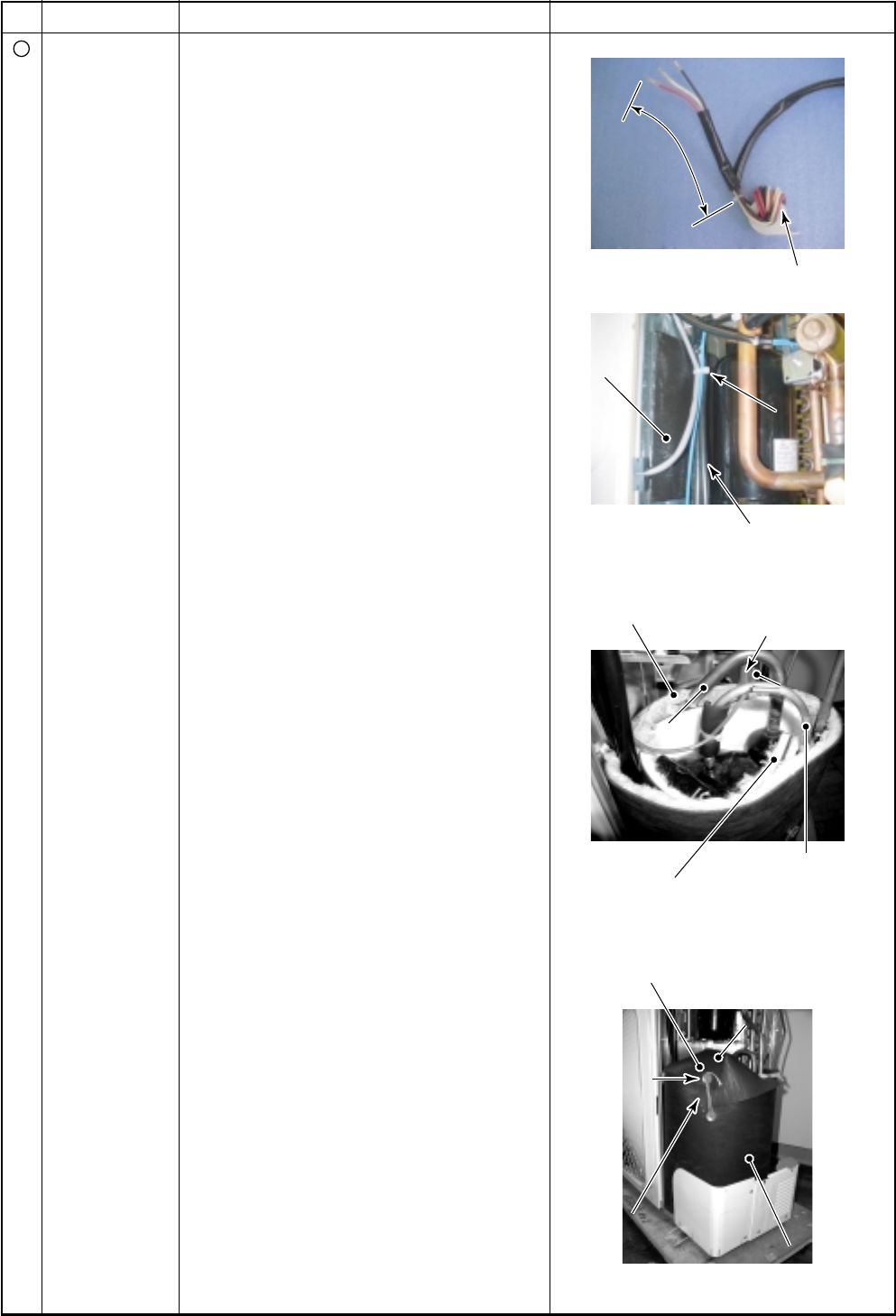

• As shown in the right figure, mount the

sound-insulation plate (rolling in, rolling out) by

passing through it between compressor and

the piping, and between the piping and the

partition plate.

• Fix TD sensor by the bundling band for

heat-proof (procured locally) via the pipe cover

so that TD sensor does not directly come to

contact with the discharge pipe.

3. Vacuuming

1) Connect the vacuum pump to the charge port

and the check joint of the gas pipe valve and

then drive the vacuum pump.

2) Carry out vacuuming until the vacuum low

pressure gauge indicates 1 (mmHg).

4. Refrigerant charge

1) Add the refrigerant amount determined by

the pipe length from the charge port of the

valve.

Pass through sound-

insulation plate

(rolling out) between

suction pipe and

header pipe.

Put the end of sound-

insulation plate

(rolling out) on the other

end at this position.

Header pipe

Header pipe

Suction pipe

Suction pipe

Discharge pipe

Pass through sound-insulation plate (rolling in)

between compressor and discharge pipe,

suction pipe and then put the end of sound-

insulation plate on the other end at this position.

There should be no clearance between sound-

insulation plate (upper) and sound-insulation plate

(rolling out).

Sound-insulation plate

Sound-insulation plate

(upper)

(upper)

Cultural rivet

Cultural rivet

Insert one side

Insert one side

under cultural rivet.

under cultural rivet.

Sound-insulation plate

Sound-insulation plate

(rolling out)

(rolling out)

Header pipe

Suction pipe

Sound-insulation plate

(upper)

Cultural rivet

Insert one side

under cultural rivet.

Sound-insulation plate

(rolling out)

Compressor lead

(Bind TD sensor lead, case thermo lead

and fan motor lead together.)

Pay attention to

Pay attention to

finished direction.

finished direction.

Partition plate

Partition plate

Bundling band

Bundling band

180

180

Pay attention to

finished direction.

Partition plate

Bundling band

180

Winding by 5 times

Wind lead wires while tightening

so that loop does not expand.