– 57 –

CAUTION

• Be sure to refer to the wiring system diagram

labeled inside the front panel.

• Check local electrical regulations for any

specific wiring instructions or limitations.

10-3-5. Piping and Drain Hose Installation

Piping and drain hose forming

• Since condensation results in machine trouble,

make sure to insulate both the connecting pipes

separately.

(Use polyethylene foam as insulating material.)

NOTE :

• Use stranded wire only.

• Wire type : minimum AWG14

Fig. 10-3-10

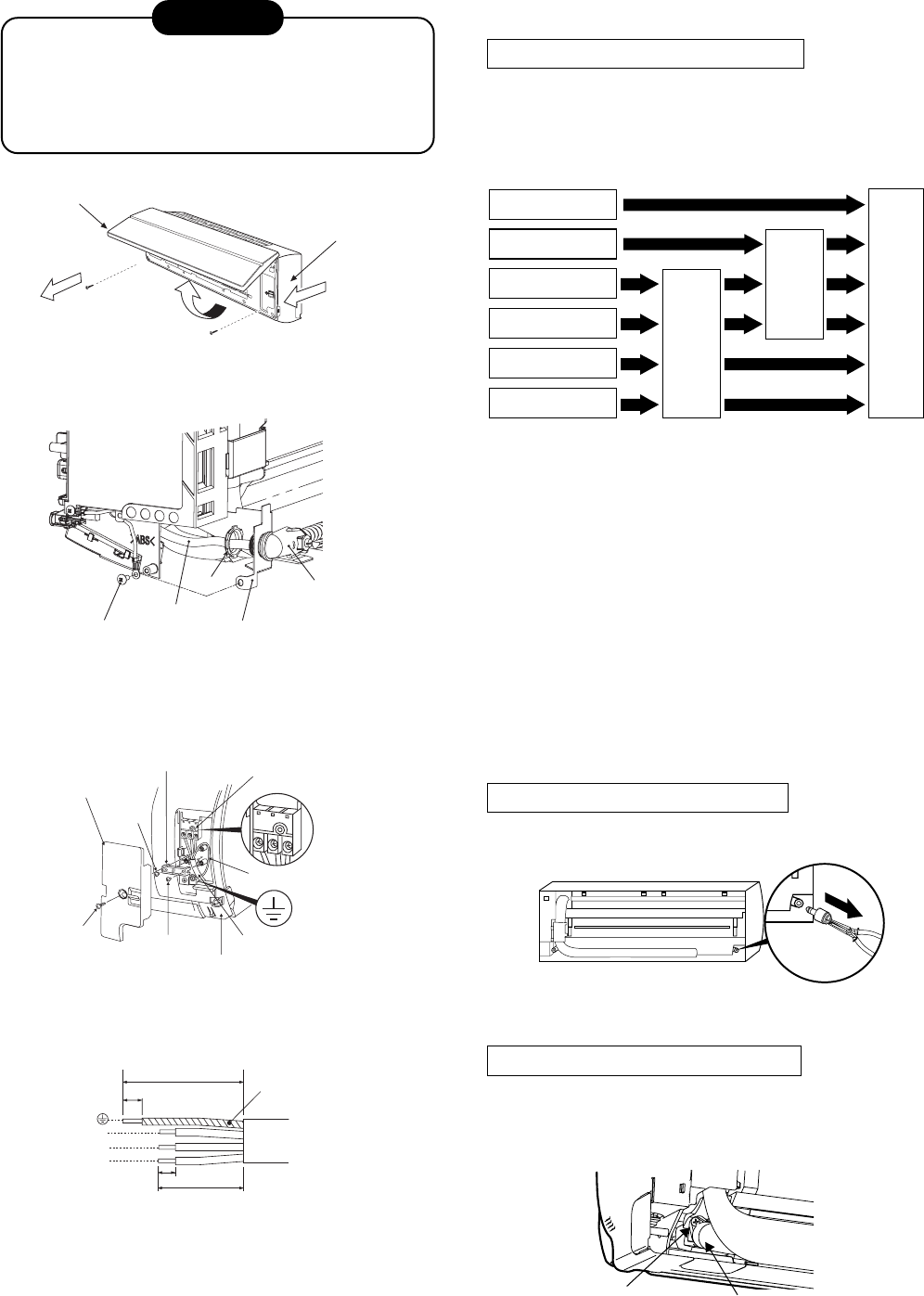

1. Die-cutting front panel slit

Cut out the slit on the left or right side of the front

panel for the left or right connection and the slit

on the bottom left or side of thefront panel for the

bottom left or right connection with a pair of

nippers.

2. Changing drain hose

For left connection, left-bottom connection and

rear-left connection’s piping, it is necessary to

relocate the drain hose and drain cap.

CAUTION

How to remove the drain cap

Clip drain cap with needle-nose pliers, and pull out.

Fig. 10-3-11

How to remove the drain hose

The drain hose is secured in place by a screw.

Remove the screw securing the drain hose, then pull

out the drain hose.

Die-cutting

Front panel slit

Changing

drain hose

Piping preparation

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Screw

Drain hose

Fig. 10-3-12

3

1

2

Air inlet grille

Front panel

L

1

L

2

S

L

1

L

2

S

Cord clamp

Terminal block

Terminal cover

Screw

Ground line

Screw

Connecting cable

Screw

Front panel

S

L2

L1

Ground

line

4-5/16 in. (110 mm)

3-5/32 in. (80 mm)

13/16 in. (20 mm)

3/8 in. (10 mm)

Fig. 10-3-9

Fig. 10-3-6

Fig. 10-3-7

Fig. 10-3-8

FILE NO. SVM-10019

Conduit pipe

Conduit mount

Fixing screw

Lock nut

Inter connecting

cable