All installations and services must be performed by qualified service personnel.

24

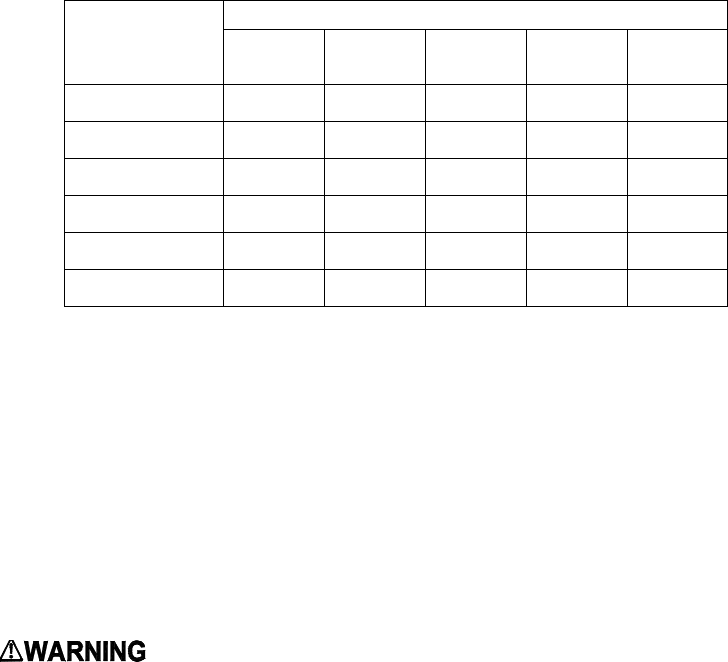

TABLE 4: Steel Pipe Size for Natural Gas (IPS)

Feet of Pipe From Meter to Burner Burner

Firing Rate,

BTU/Hr

10 20 30 40 50

50,000 1/2 1/2 3/4 3/4 3/4

100,000 3/4 3/4 3/4 3/4 1

150,000 3/4 1 1 1 1-1/4

200,000 1 1 1-1/4 1-1/4 1-1/4

250,000 1 1 1-1/4 1-1/4 1-1/4

300,000 1 1 1-1/4 1-1/4 1-1/4

All black pipe sizes shown are nominal iron pipe sizes.

Use black iron steel pipe and malleable iron fittings for natural gas service lines.

Provide rigid supports for the pipe. If the pipe size must be reduced, use

reducing couplings when possible. Avoid the use of reducing bushings. Remove

all burrs and inspect the pipe for dirt or other foreign material prior to connecting.

Maximum supply pressure for natural gas is 14.0 in. W.C. and minimum supply

for purpose of input adjustment is 4.5 in. W.C.

2. INSTALLATION OF PROPANE GAS PIPING

:

• Copper and brass tubing and fittings (except tin lined) shall not

be used if the gas contains more than a trace (0.3 grains per 100

cubic ft.) of hydrogen sulfide gas. Check with your gas supplier.

Maximum supply pressure for propane gas is 14.0 in. W.C. and the minimum

supply for purpose of input adjustment is 11.0 in. W.C.

Experience has proven that the pressure drop in the gas line running from the

outside propane gas tank to the gas appliances in a home is the most frequent

cause of equipment malfunctions. A single pressure regulator, located at the

tank, will not reliably regulate the high tank pressures (up to 200 PSIG.) down to

11.0 in. W.C. Varying pressures will occur at the appliances as outside

temperatures and usage demands vary. Two-stage regulation is the only

effective method of controlling gas pressure (refer Figure 7).