21

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 49

Step 4. FIELD WIRING

Refer to Section A for millivolt appliances and

Section B for electronic appliances. The gas

valve is set in place and pre-wired at the

factory on both models.

1. Route a 3-wire 120Vac 60Hz 1ph power

supply to the appliance junction box.

2. If the factory-provided outlet/junction box

at the right rear of the fireplace is being used,

remove the outlet box from the junction box by

removing two screws.

3. Connect the power supply wires (includ-

ing the ground supply wire) as shown in

Figures 48or 49.

(If the field-provided J-box/

outlet box is being used, all of the outlet box

wiring must be field-provided.)

4. Locate and install a low voltage (24V) wall-

mounted switch or thermostat (both field-

provided) in the desired location.

5. Connect the low voltage wire (located in-

side the bottom compartment of the unit) to

the wall-mounted switch or thermostat.

Note: The supplied 15 feet of 2 conductor wire has one

end of each conductor connected to the gas valve

circuit and the other end of each conductor placed

loose inside the bottom compartment of the unit.

6. Insert the control circuit plug into the

unswitched receptacle of the outlet box.

7. After wiring is complete, mount the outlet

box to the J-Box.

A. SIT and Honeywell Millivolt Wiring

(See Figure 46)

–

1. Select any of the following optional con-

trols: appliance-mounted (rocker switch) or

wall-mounted switch, thermostat, or one of

the optional remote control kits. If appliance-

mounted ON/OFF control is selected mount it

in the gas valve mounting bracket.

2. If wall-mounted ON/OFF control or ther-

mostat is selected mount it in a convenient

location on a wall near the fireplace.

3. Wire the control switch within the millivolt

control circuit using the 15 feet of 2 conductor wire

supplied with the unit . Caution: do not connect the

optional wall switch to a 120V power supply.

4. Alternatively, the appliance may be operated

without the use of the controls indicated in step 1,

solely by manipulating the gas valve control knob. In

order to use this method, twist the free ends of the two

conductor wire (located inside the bottom compart-

ment of the unit) together as shown in

Figure 46

.

Note: The supplied 15 feet of 2 conductor wire has one

end of each conductor connected to the gas valve

circuit and the other end of each conductor placed

loose inside the bottom compartment of the unit.

Note: The gas valve-mounted ON/OFF switch is shown

in Figure 48 or 49. It is integral with the gas valve

and should be set to the ON position.

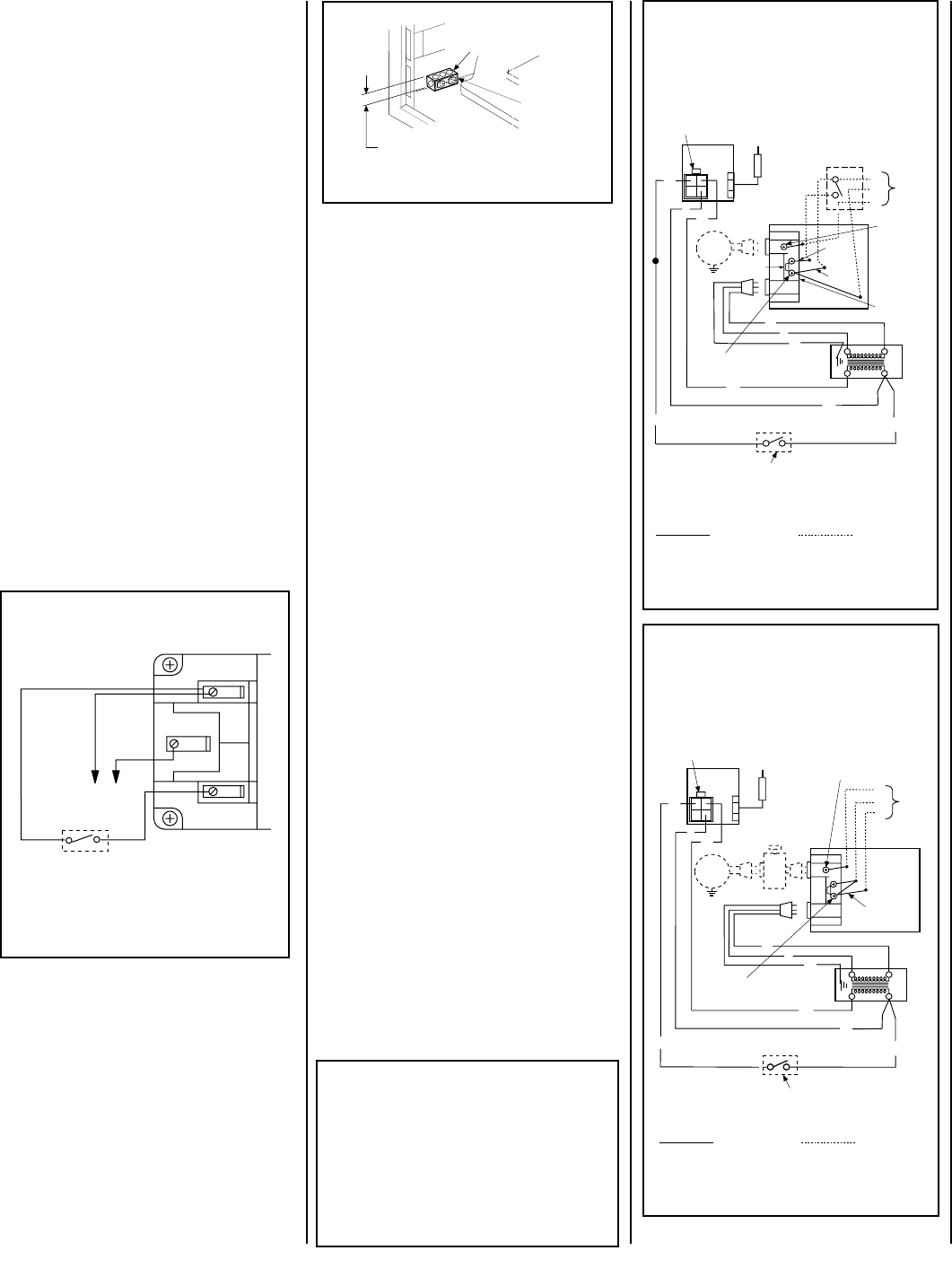

Step 5. WIRING - OPTIONAL FORCED AIR

BLOWER KIT

FBK-100, FBK-200 and FBK250 Kits

(See Figure 48 for FBK-100, FBK-200 and

Figure 49 for FBK-250 wiring)

-

An electrical outlet box (receptacle) is factory -

provided for the installation of the FBK-100, FBK-

200 and FBK-250 forced air blower kits. (An

optional field-provided outletbox/J-Box may also

be used. Electrical power must be connected to

either of these receptacles in order to operate these

blowers. Install the blower kits according to the

installation instructions provided with the kits.

Note: The tab connecting the receptacles of the

outlet box must be broken in FBK-100 and FBK-

200 blower kit applications.

B. Electronic Wiring

(See figure 48 or 49)

–

A junction box is located at the rear of the control

compartment on either side of the cabinet. The

junction box on the right side contains a factory

installed and wired outlet box (duplex recep-

tacle). Also, an optional field-provided junction

box with receptacle may be installed at the front

of the control compartment on either side of the

cabinet.

See Figure 47.

It will be held in place

by a conduit fitting and locknut (field-provided).

IMPORTANT: Ground supply wire must be

connected to the green wire attached to the

outlet receptacle's green ground screw. See

Figure 48 or 49

. Failure to do so will result in

a potential safety hazard. The appliance

must be electrically grounded in accordance

with local codes or, in the absence of local

codes, the National Electrical Code, ANSI/

NFPA 70-(latest edition). (In Canada, the

current CSA C22-1 Canadian Electrical Code.)

Figure 48

Honeywell Millivolt Wiring Diagram

If any of the original wire as supplied must be replaced,

it must be replaced with Type AWM105°C – 18 GA. wire.

Thermopile

TH

TP

TH

TP

*TWIST WIRES “A” AND “B” TOGETHER TO OPERATE UNIT

SOLELY BY MANIPULATING THE GAS VALVE CONTROL KNOB;

OR CONNECT WIRES TO OPTIONAL ON/OFF SWITCH OR WALL

SWITCH OR THERMOSTAT TO OPERATE UNIT.

*OPTIONAL ON/OFF SWITCH,

WALL SWITCH, THERMOSTAT

OR REMOTE CONTROL RECEIVER

AB

Note: The electronic appliance must be con-

nected to the main power supply.

1. If any of the original wire as supplied must be replaced,

1. it must be replaced with Type AWM 105°C – 18 GA. wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Junction Box

Transf.

120 V.

24 V

Factory Wired Field Wired

BL

Electronic Wiring Diagram (Honeywell)

Showing the Blower Wiring for the Optional

FBK-100 and FBK-200 Kits

R

W

BL

OPT

BLOWER

G

W

*OPTIONAL

ACCESSORY

SWITCH

120

VAC.

BK

W

Gas Valve

B

R

IGNITER

PILOT

ASSEMBLY

Break Off

Tab

BK

G

*Blower speed control switch is provided in FBK200 blower kit.

Outlet Box

Green Ground

Screw

Hot side of Outlet

Schematic Representation Only

**ON/OFF Switch (Integral

with Gas Valve)

**Leave the ON/OFF switch, which is integral

with the gas valve, in the ON position.

OPTIONAL APPLIANCE-MOUNTED ON/OFF SWITCH

OR OPTIONAL WALL SWITCH

OR OPTIONAL THERMOSTAT

OR OPTIONAL REMOTE RECEIVER

Red

pigtail

Black

pigtail

White Wire

to Opposite

Side

G

1. If any of the original wire as supplied must be replaced,

1. it must be replaced with Type AWM 105°C – 18 GA. wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Transf.

120 V.

24 V

Factory Wired Field Wired

BL

Electronic Wiring Diagram (Honeywell)

Showing the Blower Wiring for the Optional

FBK-250 Kits

R

WH

BL

OPT

BLOWER

G

W

120

VAC.

BK

W

Gas Valve

B

R

IGNITER

PILOT

ASSEMBLY

BK

G

Outlet Box Green

Ground Screw

Hot side of Outlet

Schematic Representation Only

*ON/OFF Switch (Integral

with Gas Valve)

White Wire

To Opposite

Side

Optional FBK-250

Module

*Leave the ON/OFF switch, which is integral

with the gas valve, in the ON position.

G

OPTIONAL APPLIANCE-MOUNTED ON/OFF SWITCH

OR OPTIONAL WALL SWITCH

OR OPTIONAL THERMOSTAT

OR OPTIONAL REMOTE RECEIVER

*Narrow (2 ¹⁄₈ inch Wide)

J-Box Required

See Figure 12 on page 8

for Optional Electrical

Inlet Knockout Location

*Field-Provide

Junction Box

and Duplex

Receptacle

Optional J-Box/Outlet Box

(Left Side Shown)

Figure 47

Figure 46

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.