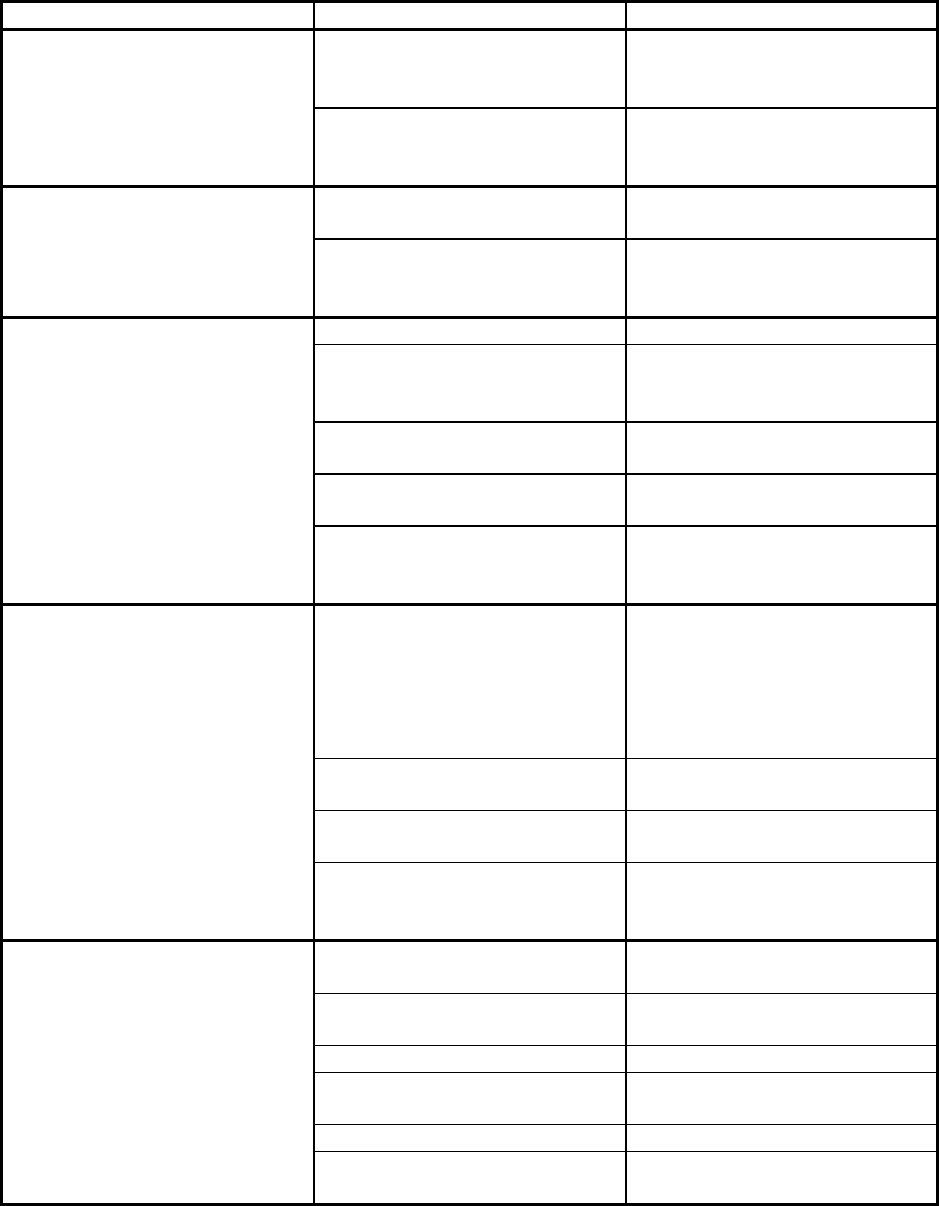

Cabinet Series Dehumidifying Dryer 50

Problem Possible cause Corrective action

Airflow valve sticking or

failing to shift.

Check for proper operation of

valve actuators. Repair or

replace if necessary.

Loss or reduction in drying

capacity. (Cont’d.)

Blower fins filled with dust or

contaminants.

Remove blower side plate,

clean baffles, replace.

Replace filter elements.

Insufficient power to PLC

(Power LED is off).

Check power supply and

power wiring to PLC.

PLC Regeneration Bed LED

indicators both off.

Faulty PLC (PLC Power light

is on, Run light is off, and/or

Error light is on).

Replace PLC.

Regenerating bed cool down. None.

Blower Input indicator is off.

Verify that blower contactor is

on. Check input wiring to

PLC.

Process air in high-

temperature condition.

None.

Insufficient power to PLC

(Power light is off).

Check power supply and

power wiring to PLC.

PLC Regeneration Heater

Left/Right output indicators

both off.

Faulty PLC (PLC Power light

is on, Run light is off, and/or

Error light is on).

Replace PLC.

Process temperature set too

high due to operator error.

Check resin manufacturer’s

data sheet for proper drying

temperature. Make sure plant

personnel are aware of the

correct process temperature

set point.

High temperature alarm not

set properly.

Reset high temperature

alarm.

Process set point is out of

acceptable range.

Restore temperature

controller to factory pre-sets.

Material in drying hopper

cakes, or meltdown occurs.

Function set for degrees

Celsius (ºC), set point at

degrees Fahrenheit (ºF).

Verify correct Celsius or

Fahrenheit settings.

Burned out regeneration

heater.

Repair or replace.

Contaminated or worn out

desiccant.

Replace.

Leaking process air hoses. Repair or replace.

Dryer operates beyond its

capacity.

Check dryer and drying

hopper sizing.

Bad dew point sensor. Replace.

Poor dew point performance.

Fouled dew point sensor

manifold.

Clear obstruction. Air should

flow freely through sensor.