18

Lime scale should be removed from the elements by dissolving the

accumulation in UN•LIME® delimer. UN•LIME is a non-muriatic

delimer, available through your dealer or distributor. Do not use

muratic or hydrochloric acid base deliming solutions to remove lime

scale from the elements. Do not pour delimer into tank.

All models:

1. Turn off electrical disconnect switch.

2. Drain the boiler following DRAINING instructions.

3. Remove the cabinet panel which covers the heating elements.

• Remove insulation as necessary to reach the element area.

4. Remove the bolts from each element and remove the elements

from the opening.

• Disconnect element wiring as necessary.

• Use a twisting, pulling action to remove elements scaled beyond

the size of the tank opening.

• Brush loose scale from elements.

• Silicates, sulfates and aluminates must be removed by scraping or

other mechanical means. Lime scale dissolvents will not remove

these types of scale which are occasionally encountered.

5. Lime scale removal:

• Place limed ends of heating elements into UN•LIME delimer

and allow scale to dissolve. Do not permit delimer or water to

contact heating element electrical terminals.

6. Flush cleaned ends of elements with water when deliming or

cleaning is completed.

7. Remove sediment and scale from the tank bottom through the

tank cleanout.

• The make-up water valve and boiler drain valve may be opened

to ush during the cleanout process.

8. Clean remaining gasket material from tank and element anges. Do

not reuse original element gasket. The element gasket is Part No.

5109.

9. Replace elements as follows:

• Put a new gasket on each element.

• Install into tank opening.

• Uniformly tighten element bolts. Torque to approximately 32 ft /lbs.

10. Connect element wiring as necessary.

11. Follow FILLING instructions to restore boiler to service.

• Check for water leaks around elements and proper

operation when boiler is lled.

• Replace insulation and cabinet panel.

TROUBLESHOOTING CHECKLIST

Before calling for service, check the following points to see if the

cause of trouble can be identied and corrected. Reviewing this

checklist may eliminate the need of a service call and quickly restore

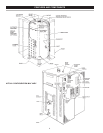

the boiler to service. The illustration on page 5 identies the location

of most of the boiler components.

BE SURE TO TURN OFF THE ELECTRICITY WHEN CHECKING

EQUIPMENT.

Not enough or no hot water

1. Be certain the electrical disconnect switch serving the boiler is in the

ON position. The pilot switch(es) on the cabinet front should be on.

• In some installations the boiler electrical service may be limited

by the power company or boiler controls. If the boiler operates

on a controlled circuit heat may be effected.

2. Check the fuses.

• The electrical disconnect switch usually contains fuses.

• The boiler has fuses located behind the cabinet door, see page

5 for location.

3. If the water was excessively hot, and is now cold, the high

temperature cutoff may have operated (manual reset equipped

models).

• To reset, turn off electricity and remove the back panel and push

the reset button.

• Repeated operation of the high temperature cutoff should be

investigated by your servicer.

4. The capacity of the boiler may have been exceeded by a large

demand for heat.

• Large demands require a recovery period to restore water

temperature.

5. Sediment or lime scale may be affecting boiler operation. Refer to

MAINTENANCE for details.

Water is too hot

1. Refer to TEMPERATURE REGULATION.

Boiler makes sounds

1. Sediment or lime scale accumulation on the elements may cause

sizzling and hissing noises when the boiler is operating.

• The sounds are normal , however, the tank bottom and elements

should be cleaned. Refer to MAINTENANCE for details.

2. Some of the electrical components of the boiler make sounds

which are normal.

• Contactors will “click” or snap as the boiler starts and stops.

• Transformers and contactors often hum.

Water leakage is suspected

1. Check to see if the drain valve is tightly closed.

2. If the outlet of the relief valve is leaking it may represent:

• Excessive water pressure or air in the system.

• Faulty relief valve.

3. Examine the ange area of the elements and tank cleanout for

gasket leakage.

• Tighten the bolts or, if necessary, follow the WATER AND LIME

SCALE REMOVAL procedure to replace the gaskets.

SYSTEM WATER TEST

System water test

Review SYSTEM CLEANING section, for a description of six problems

which result from loss of system chemical stability. Chemical stability

is checked by:

1. Draw off water from system. Is it dirty, discolored or odorous?

2. What is the pH of the system water? It should be neutral or slightly

alkaline.

3. Does “air” purged from system vents burn? If so, the “air” is

actually gas.

If any of the above conditions are present, all waterways should be

cleaned and the water adjusted to an alkaline condition.

Ifyoucannotidentifyorcorrectthesourceofmalfunction:

1. Place the boiler electrical disconnect switch in the OFF position.

2. Close the make-up water inlet valve to the boiler.

3. Contact your servicer.