22

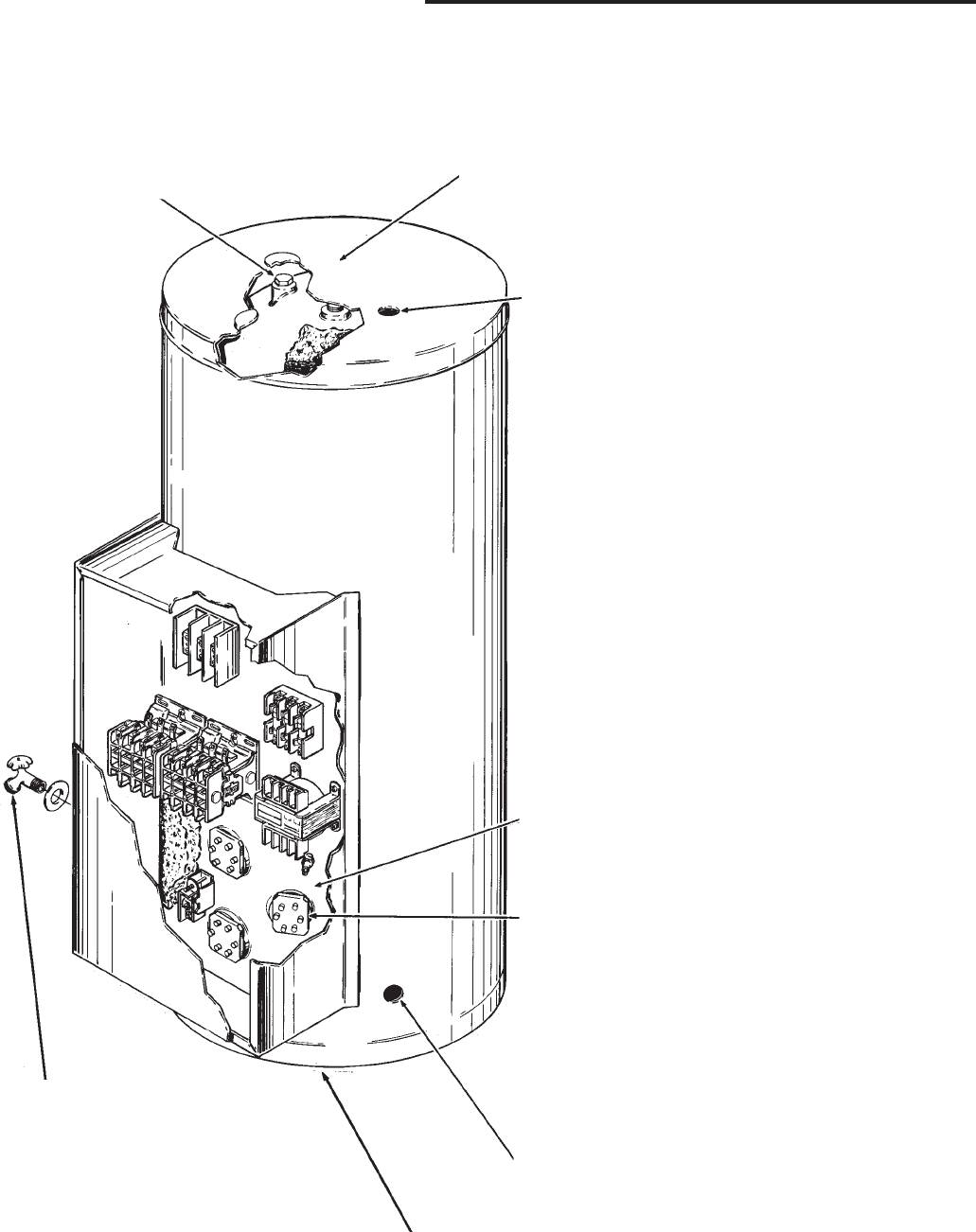

LEAKAGE CHECKPOINTS

INSTRUCTIONS: USE THIS ILLUSTRATION AS A GUIDE WHEN CHECKING FOR SOURCES OF WATER LEAKAGE. YOU OR

YOUR DEALER MAY BE ABLE TO CORRECT WHAT APPEARS TO BE A PROBLEM.

Water on side of the tank may be condensation due to the

panel or insulation not being in place.

Relief valve operation and leakage may be due to water

expansion during heating cycle or foreign material on seat

of valve. If the valve is not piped to an open drain the

released water could be mistaken for a leaking heater. To

check where threaded portion enters tank, insert Q-tip or

similar absorbent material between jacket opening and

valve to swab spud area. Remove valve* if leak is indicated

and repair with pipe joint compound.

Water leaks at the elements may be due to:

1. Defective element which leaks at terminals or through

flange. Replace element*.

2. Loose element/gasket leak:

Flange type: Tighten screws with wrench. If leak

continues remove element* and discard gasket.

Clean gasket seating areas and reinstall element

with new gasket.

NOTE: Part No. 5288 scale cleaning replacement

screws available where threads have become rusted

or damaged, preventing tightening.

Condensation and dripping may appear on pipes when cold

water temperature is low. Pipe fitting may be leaking.

All water which appears at the heater bottom or on the surrounding floor

may be caused by condensation, loose connections or relief valve

operation and leakage. Do not replace the heater until a full inspection of

all potential leak points is made and corrective steps taken to stop the

leak. Leakage from other appliances, water lines or ground seepage

should also be suspected until proven otherwise.

Where possible, remove or lift top cover to examine threads of

fittings installed into tank for evidence of leakage. Correct fitting

leaks as necessary.

Drain valve leakage could be from the

valve itself. Either correct the problem

or replace the valve.* To check for

leakage where threaded portion enters

tank, insert Q-tip or similar absorbent

material between jacket opening and

valve to swab spud area. Remove valve*

if leak is indicated and repair with pipe

joint compound.

*Contact your dealer as it is necessary

to shut off electricity and drain tank to

perform procedure.

ANODE