21

PLANNING THE VENT SYSTEM

Plan the route of the vent system from the discharge of the blower

to the planned location of the vent terminal. Refer to VAA instruction

on page 26 while planning the vent system.

1. Layout total vent system to use a minimum of vent pipe and elbows.

2. Thiswaterheateriscapableofventinguegasesequivalentto

25’(7.6m)of2”pipe,65’(19.8m)of3”pipe,or128’(39.0m)of

4”pipeaslistedinTable1.

TABLE 1

Number of 2” Maximum 3” Maximum 4” Maximum

90° Elbows Pipe - ft. (m) Pipe - ft. (m) Pipe - ft. (m)

1 20(6.1) 60(18.3) 120(36.6)

2 15(4.6) 55(16.8) 112(34.1)

3 10(3.0) 50(15.2) 104(31.7)

4 -- 45(13.7) 96(29.3)

5 -- 40(12.2) 88(26.8)

6 -- 35(10.7) 80(24.3)

Theminimumventlengthsforeachofthepipesizesisone90°ontopof

theunitplus2’(61cm)ofstraightpipeandtheappropriatetermination.

NOTE:Theequivalentfeet(m)ofpipelistedaboveareexclusive

of the termination. That is, the termination, with an installed

screen, is assumed to be in the system and the remainder of the

system must not exceed the lengths discussed above.

3. The blower discharge adapter is made to accept only straight

sectionsof2”pipe.Tostart,aminimumof2inches(5.1cm)of2”

pipe must be attached to the blower discharge, see Figure 17.

If using 2” inch vent pipe:

Aminimumof2inches(5.1cm)mustbeattachedtotheblower

beforetherstelbow.Aftertherstelbowaddtheadditional

venting required for the installation. The total system cannot

exceed the lengths discussed above, where each elbow is equal

to5feet(1.5m)ofstraightpipe.

If using 3” or 4” inch vent pipe:

Twoinches(5.1cm)ofpipemustbeattachedtoblowerdischargebefore

adding a reducer to acquire desired pipe diameter. An appropriately

sized45degreeschedule40DWVelbow(eldsupplied)ventterminal

mustbeobtainedwithanequivalentscreen(suppliedinventkit).

The total system cannot exceed equivalent pipe lengths discussed

abovewhereeachelbowisequalto5feet(1.5m)ofstraightpipe

(3”ventpipe)or8feet(2.4m)ofstraightpipe(4”ventpipe).

U.S. Installations

NOTE: ThisunitcanbeventedwithPVCpipematerials(DWV

ASTM-D2665 or CSA B181.2; Schedule 40, 80, 120 ASTM-D1785

orCSAB137.3;orSDRSeriesASTM-D2241orCSAB137.3),CPVC

pipematerials(CPVC41ASTM-D2846orCSAB137.6;Schedule40,

80ASTM-F441orCSAB137.6;orSDRSeriesASTM-F442),ABSpipe

materials(Schedule40DWVASTM-D2661orCSAB181.1).Fittings,

other than TERMINATIONshouldbeequivalenttoPVC-DWVttings

meetingASTMD-2665(UseCPVCttings,ASTMF-438forCPVCpipe

andABSttings,ASTMD-2661/3311forABSpipe).IfCPVCorABS

pipeandttingsareused,thenpropercementmustbeusedforalljoints,

includingjoiningpipetoTermination(PVCMaterial).Iflocalcodesdonot

allow use of PVC termination when a material other than PVC is used

forventing,thenanequivalentttingofthatmaterialmaybesubstituted

ifscreeninPVCterminalisremovedandinsertedintonewtting.

PVC Materials should use ASTM D-2564 Grade Cement; CPVC

Materials should use ASTM F-493 Grade Cement and ABS Materials

should use ASTM D-2235 Grade Cement.

Canadian Installations

Installation of this water heater must comply with CAN/CSA B149.1

- Natural Gas and Propane Installation Code which requires the vent

systemcomponentsbecertiedtoULCS636.

ThiswaterheaterhasbeendesigncertiedtobeventedwithPVC

pipecertiedandmarkedascomplyingwithULCS636.Thiswater

heater is supplied with a 2 inch 22.5 degree termination elbow that is a

specialttingthatmustbeusedwiththisappliance.Anyoutletpiping,

ttingsandglueusedtoventthisappliancethatisnotsuppliedbythe

manufacturer must comply with the ULC S636 requirements.

If water heater is being installed as a replacement for an existing power

vented heater in pre-existing venting, a thorough inspection of existing

venting system must be performed prior to any installation work. Verify

that correct material as detailed above has been used, and that minimum

or maximum vent lengths and terminal location as detailed in this manual

have been met. Carefully inspect entire venting system for any signs

of cracks or fractures, particularly at joints between elbows and other

ttingsandstraightrunsofventpipe.Checksystemforsignsofsagging

or other stresses in joints as a result of misalignment of any components

in system. If any of these conditions are found, they must be corrected in

accordance with venting instructions in this manual before completing

installation and putting water heater into service.

NOTE: A. For water heaters in locations with high ambient

temperatures(above100°F)itisrecommendedthatCPVCpipe

andttingsbeused.B.A22.5degreeelbow(2”ventpipe)ora45

degreeelbow(3”and4”ventpipe)withaninstalledscreenVENT

TERMINAL must be used in all cases.

4. There will be some installations where condensate will be formed

in the horizontal runs of the vent system. This condensate will

run into the condensate boot attached to the blower and out the

tting.Thewaterheaterisshippedwithcondensatehosethat

attachestothettingonthecondensateboot.NootherTeeor

ttingisrequired.SeeFigures17,20and21.

CONDENSATE

This water heater is a condensing unit and requires a drain to be located

in close proximity to allow condensate to drain safely. One hose from

blowerhousing,twoexiblehosesfrombloweroutletadaptor,alongwith

anotherexiblehosefromVAAifinstalled,runtobarbttingsonvent

pipeassembly#2.Hoseisclampedbyrubberclipsandexiblehoses

by a clamp on jacket top cover. See Figure 17. Condensate drains from

theunitattheexhaustteelocatedatthebottomoftheunit(seegure

16).Condensatefromthiswaterheaterismildlyacidic.Pleasenote

that some local codes require that condensate is treated by using a pH

neutralizinglterpriortodisposal.

NOTE:Itisimportantthattheeldsupplieddrainlinesbeyond

the1/2”adaptorofventpipeassembly#1shouldbeinstalled

continuously tilted downward toward an appropriate drain. See Figure

16. If these instructions are not followed or if condensate drain line

is blocked, water will spill from condensate trap. Do not block the

holes in the hex plug on top of a small tee in vent pipe assembly

#1. As with every water heater installation, a drain pan should be

used to prevent water damage to surrounding area. If necessary,

a condensate pump with an incorporated reservoir may be used to

pump water to an appropriate drain. To avoid condensate spillage,

selectapumpwithanoverowswitch.

Caution must be used to ensure that drain is free and clear of debris

andwillnotallowbackowthroughthecondensatedrainline.

Consideration must be given to avoid freezing of the condensate

lines which could result in excessive build up of condensate inside

the water heater. Waterproof heat tape may be required to prevent

freezing of condensate lines. Please ensure that the outlet of

condensate drain does not create a slippery condition which could

lead to personal injury. Care should be taken to ensure there is no

kink or twist in any condensate hose. If a VAA is not installed, the

unusedbarbttinginventpipeassembly#1shouldbepluggedusing

one of the break-away plugs.

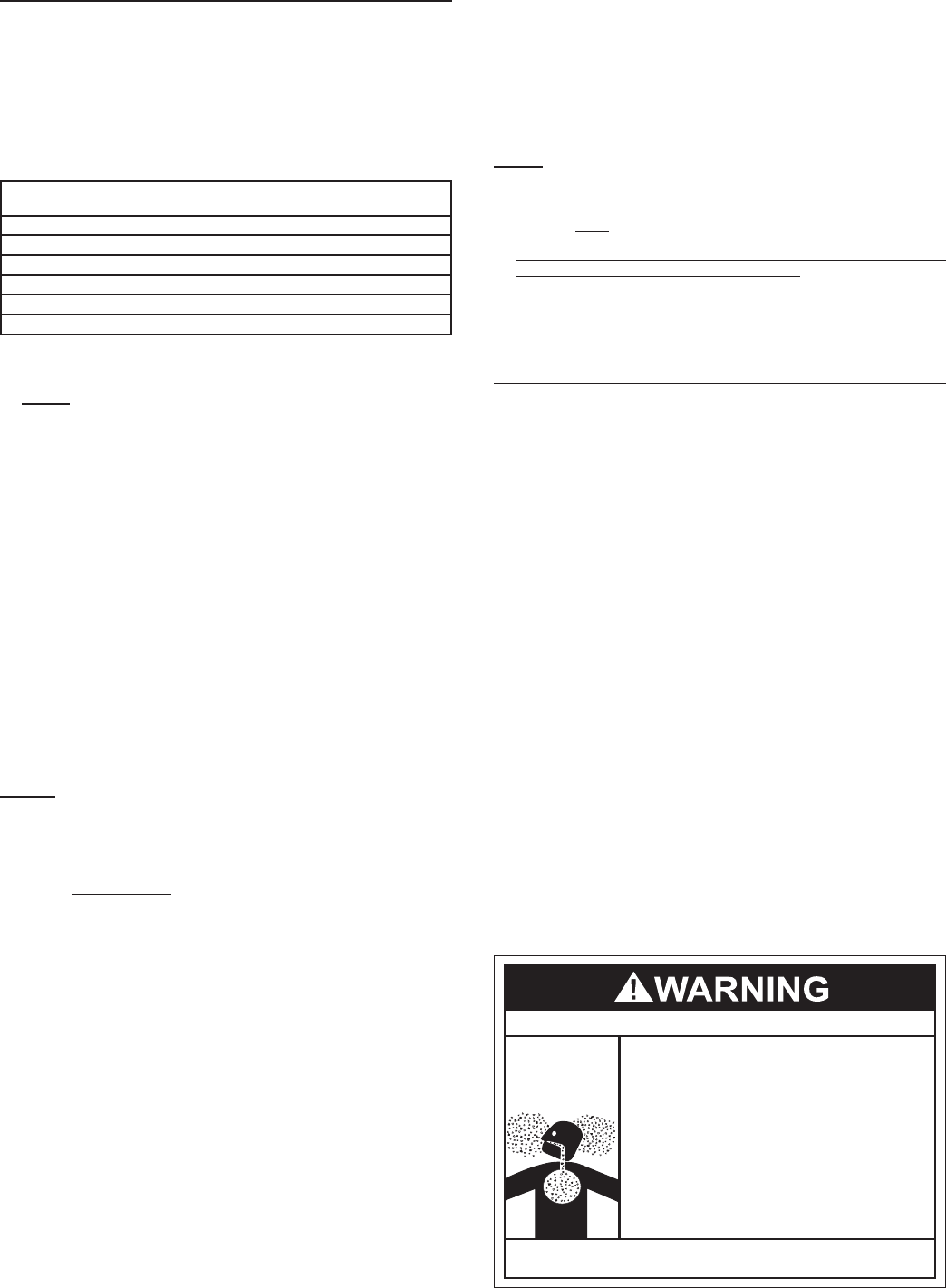

Breathing Hazard - Carbon Monoxide Gas

•

Do NOT block the holes in the hex plug of vent pipe

assembly #1.

•

Do NOT elevate any portion of the field supplied drain

line beyond the 1/2" adaptor above the adaptor. This

must be true for entire length of the drain line including

the exit into an appropriate drain

.

•

Condensate lines must be free and clear of debris and

must not allow back flow through drain line. Condensate

lines must be able to flow freely to an appropriate drain.

•

Do not allow condensate lines to become crimped closed.

•

Analyze entire vent system to make sure that condensate

will not become trapped in a section of vent pipe and

therefore reduce open cross sectional area of vent.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.