16 ► MAXFORCE BREAKER User Manual

OPERATION

EACH DAY

• Checkforlooseormissingfasteners.Tightenorre-

placeasneeded.

• Inspecttoolretainingpinsandpocketsforwear.

• Checkforhydraulicleaksatallttingsandhoses.

Replaceanydefectivehoses.

• Applygreasetothegreasettinginthelowerbody

each morning. Grease as needed throughout the

workday.

• Inspectthelowerbushing,toolretainer,toolretainer

pins.Reseatorreplaceifnecessary.

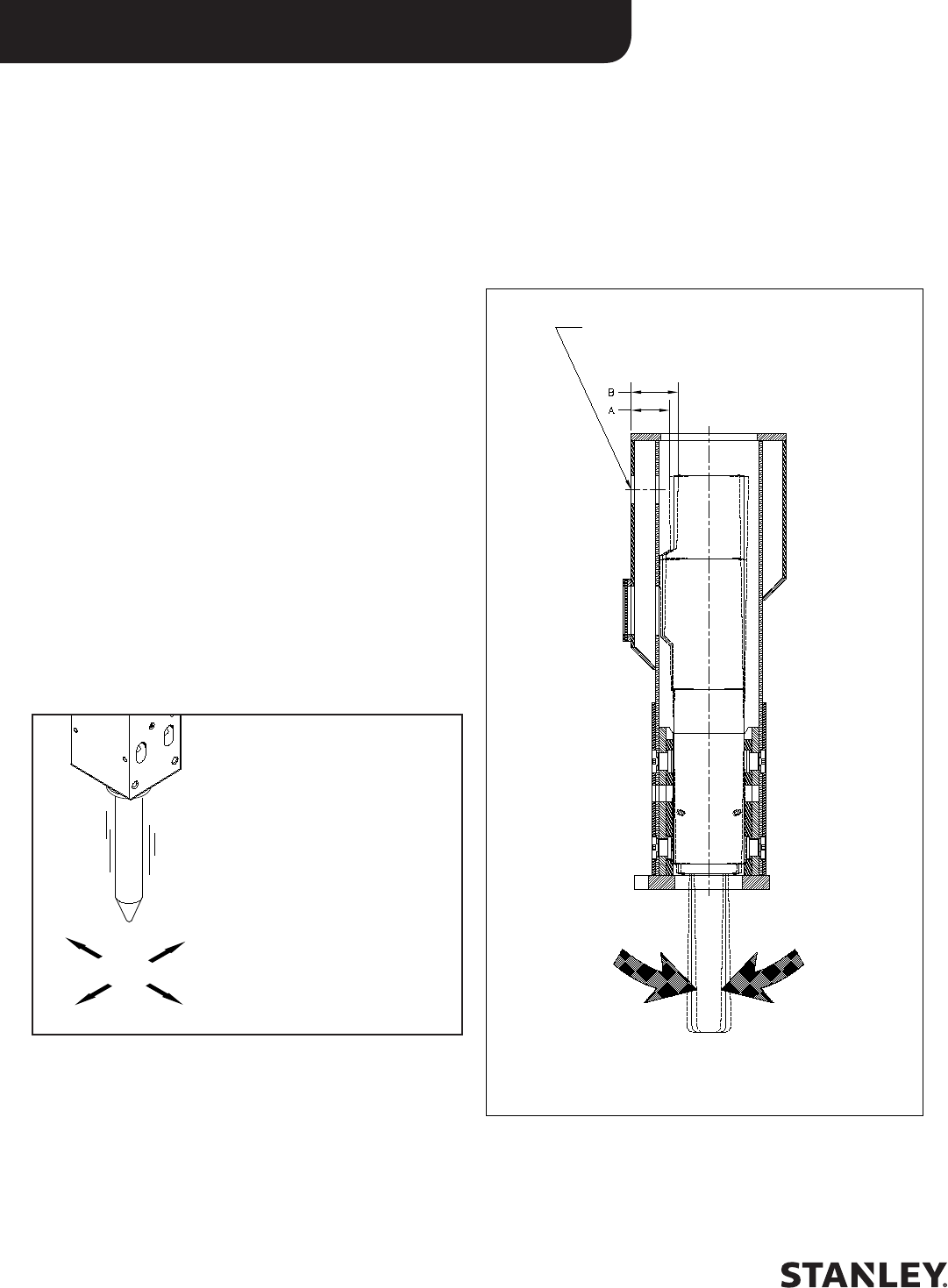

TOOL STOP & LOWER BUSHING

Inspectthetoolstop,andlowerbushingforexcessive

gallingandmetalpickuponthetoolbit.Alsocheckfor

cracks.Ifcracksarepresent,thepartsmustbereplaced.

Theextentofwearofthetoolstopandlowerbushing

andthetoolbitcanbecheckedbymovingthetoolbit

backandforthandmeasuringthegapbetweenthetool

bitandthelowerbushing.Ifthegapismorethan0.354

in./9mmthetoolstop,lowerbushing,andthetoolbit

shouldbereplaced.Agapinexcessof0.354in./9mm

willcausedamagetothepiston.Donotjustreplacethe

toolbitorthelowerbushingindividuallyasthiswillresult

inprematurewearofthereplacedcomponent.Itisrec-

ommendedtoreplaceallworncomponents.

MOVE THE TOOL BIT

BACK & FORTH &

MEASURE THE GAP

BETWEEN TOOL BIT &

LOWER BUSHING

Figure12.CheckingforWear

PERIODIC MAINTENANCE CHECKS

• Periodically checkwear padclearance bymoving

thepowercellbackandforth.Setthebreakeronthe

bitandthenusetheexcavatortomoveitfromside

tosideasshownintheillustration.Ifthedeection

exceeds1.5inches,replacethewearpads.

CHECKING WEAR PLATE WEAR

MEASURETHROUGHHOLECENTERANDIF

DIFFERANCEBETWEENA&BISGREATER

THAN1.500,REPLACEWEARPLATES.

PUSHTOOLEACHWAYFORMEASUREMENT.