Specifications

Specification Value

Marley

/

NC Class Stainless Cooling Tower

/

Specifications: Options

19

Inlet Flow Control Valves:

8.2: Add the following to the end of the

paragraph: Heavy-duty flow-regulator

valves shall be provided at the hot

water inlet connections. These valves

shall be disc-type, with cast iron

bodies and stainless steel operating

stems. There shall be a locking handle

to maintain the valve setting in any

position. Valves shall be right-angle

configuration, precluding the need for

inlet elbows.

Equalizer Flume Weir Gates:

11.2: Add the following paragraph under

Cold Water Collection Basin: The

interconnecting flume between cells

shall be equipped with a removable

cover plate to permit the shutdown of

one cell for maintenance purposes, or

to permit independent cell operation.

Sound Control

1.2 Add the following paragraph under

Base: The cooling tower shall be quiet

operation, and shall produce an overall

level of sound not higher than _______

dB(A) measured at _______ m from the

locations in the table below. All low

noise options and combinations shall

be CTI Certified for thermal perfor-

mance.

Inlet Sound Attenuation

1.3 Add the following paragraph under

Base: The cooling tower shall be

equipped with inlet sound attenuation

baffles positioned and spaced verti-

cally. The baffles will be spaced across

the entire length and extend the full

height of the air inlet. The baffles will

be constructed of perforated sheet

metal and contained within a steel

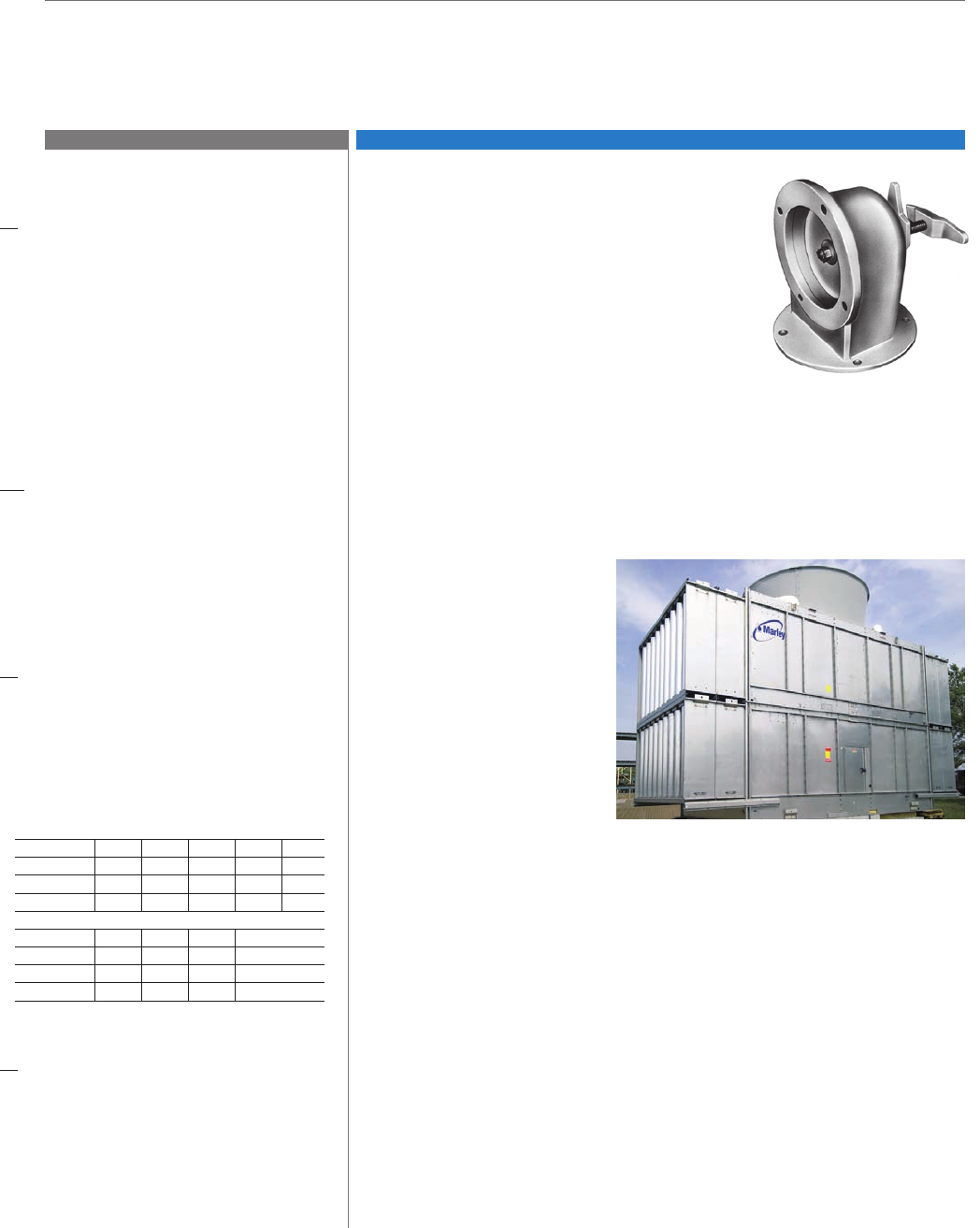

■ Marley flow-control valves have been a

favorite of users since the 1950s. They

remain serviceable for the life of the tower

and provide a continuing means of flow-

regulation between hot water basins—and

between cells of multicell towers as well.

■ Where it is your intention to be able to operate both cells of the tower

while the flume cover plate is installed, separate outlet connections,

float valves and overflows must be provided for each cell. Likewise, this

would require separate sensors and controls for basin heater systems,

if installed.

■ Sound produced by a

standard NC Cooling

Tower operating in an

unobstructed environ-

ment will meet all but

the most restrictive

noise limitations—and

will react favorably to

natural attenuation.

Where the cooling

tower has been sized

to operate within an

enclosure, the enclosure itself will have a damping effect on sound.

Sound also declines with distance—by about 5 or 6 dB(A) each time the

distance doubles. Where noise at a critical point is likely to exceed an

acceptable limit, you have several options—listed below in ascending

order of cost impact:

• Where only a slight reduction in noise will satisfy—and the source of

concern is in a particular direction—merely turning the cooling tower

may be the answer. Less sound emanates from the cased face of the

cooling tower than does from the air intake face.

• In many cases, noise concerns are limited to nighttime, when ambi-

ent noise levels are lower and neighbors are trying to sleep. You can

usually resolve these situations by using two-speed motors—operating

the fans at reduced speed without cycling “after hours”. The natural

nighttime reduction in wet-bulb temperature makes this a very feasible

solution in most areas of the world, but the need to avoid cycling may

cause the cold water temperature to vary significantly.

• A Marley Variable Speed Drive automatically minimize the tower’s

noise level during periods of reduced load and/or reduced ambient

Location 63 125 250 500 1000

Discharge

Air Inlet

Cased Face

Location 2000 4000 8000 Overall dB(A)

Discharge

Air Inlet

Cased Face

➠