12

Membrane Pressure Vessel Relocation

Use ONLY Dayco Imperial Nylo-Seal 88-NSR-1/2 tubing for high pressure connections.

Pay attention to the direction and flow path of the tubing before disassembly. Make sure

that you reinstall the tubing in the same manner. Rotate the 90 degree high pressure tube

fittings on the Clark Pump for ideal tube runs. The high pressure fittings are typically pre-

installed at the factory. These fittings seal with an O-ring and require no Teflon tape or pipe

dope. Loosen the backing nut, rotate the fitting, and reseat the backing nut.

Follow the high pressure tube connection instructions on the next page. Connect the

tubes to one of the components, secure the tube runs, and then trim and connect to the other

component. A 90 degree bend in a tube is better than a 90 degree fitting. A tube, when

mounted, should have at least one gentle bend to allow for expansion. Do not connect a

tube straight between hard mounted fittings.

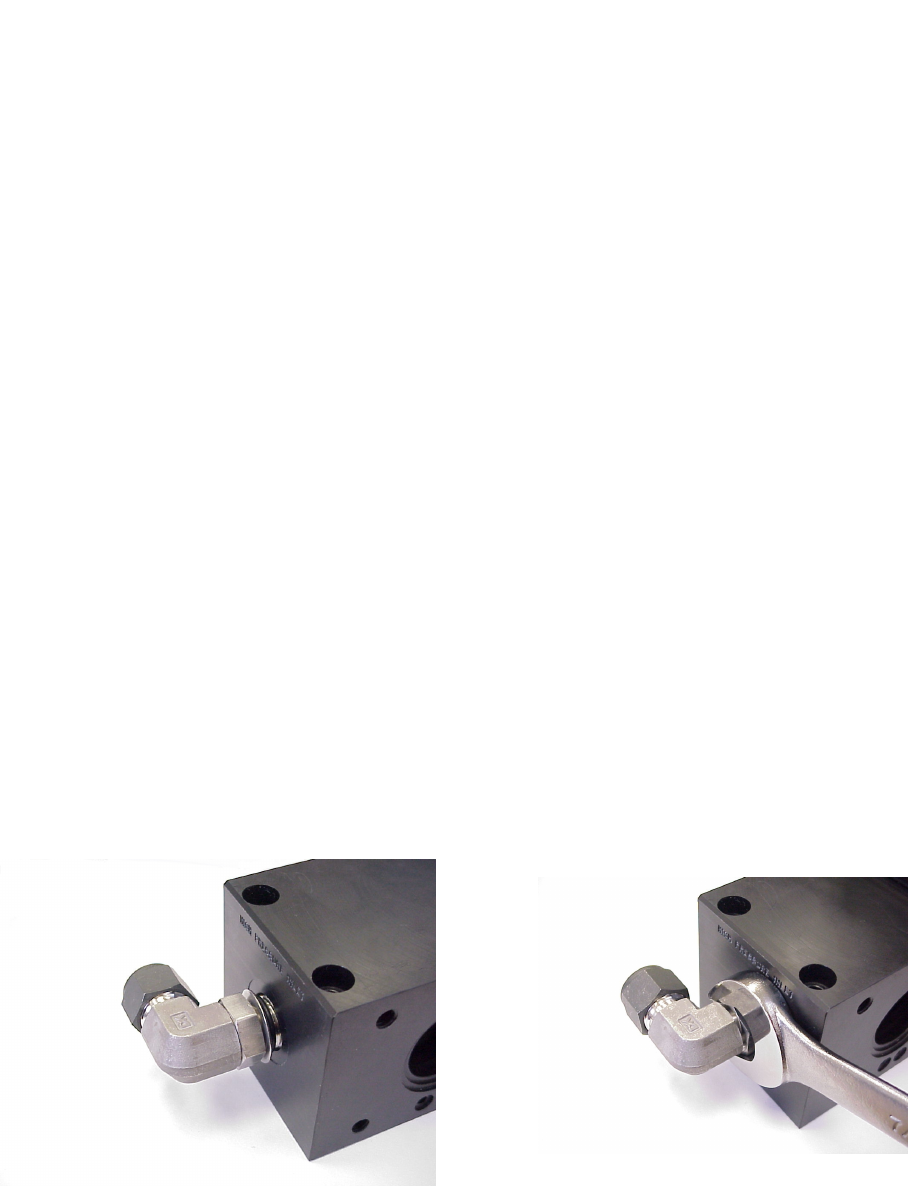

When connecting the tubes to their components, be sure to hold the fitting body with a

wrench during the final tightening. Of special note are the stainless steel tube fittings on the

membrane housing which seal with an O-ring and should be seated all the way in, but need

only to be snug, not tight as with tapered threads. Hold the fitting with a wrench while in-

stalling the tube.

The fittings on the Clark pump have an O-ring seal and can be re-oriented by backing out

the O-ring stop nut. Rotate the fitting to align with the tube and tighten the nut just past

hand tight. Do not over tighten!