VICTORY 5

HORIZONTAL PRESSURE VENTING

All VICTORY models are certified for horizontal pressure

venting with the following restrictions:

1. Vent Material

A

. The vent system for horizontal venting must be UL list-

ed single wall Saf-T 3" diameter #AL 29-4C

▲

stainless

steel manufactured by Heat-Fab, Inc. The manufactur-

ers’ part numbers for various items of the vent system

are listed in SLANT/FIN Parts List, Publication # V-

10PL.

B. DO NOT use plastic or galvanized flue pipe.

C. For horizontal, through the wall venting, the 3" flue

c

ollar and adapter MUST be used. The vent pipe size

must be 3" diameter from the boiler to the outside ter-

mination. Certain restrictions on the location of the

vent terminal are specified in APPENDIX "B" and must

be followed.

2

.

Installation

A. Figures 7 and 8 show the allowed venting arrange-

ments. The maximum equivalent vent length is 40 feet

plus vent terminal for all models except V-180 which

has a 20 feet maximum equivalent vent length. Every

90° turn in the vent piping is equivalent to 5 feet of

straight run, (eg. a V-120 system with 3 elbows and the

outside terminal would allow 40 - 15 = 25 feet of

straight run). The minimum allowable equivalent vent

length is 2 feet and 1 elbow plus vent terminal for all

models, see table below. NOTE: For best operation,

elbows should be at least five diameters apart other-

wise maximum vent length should be reduced.

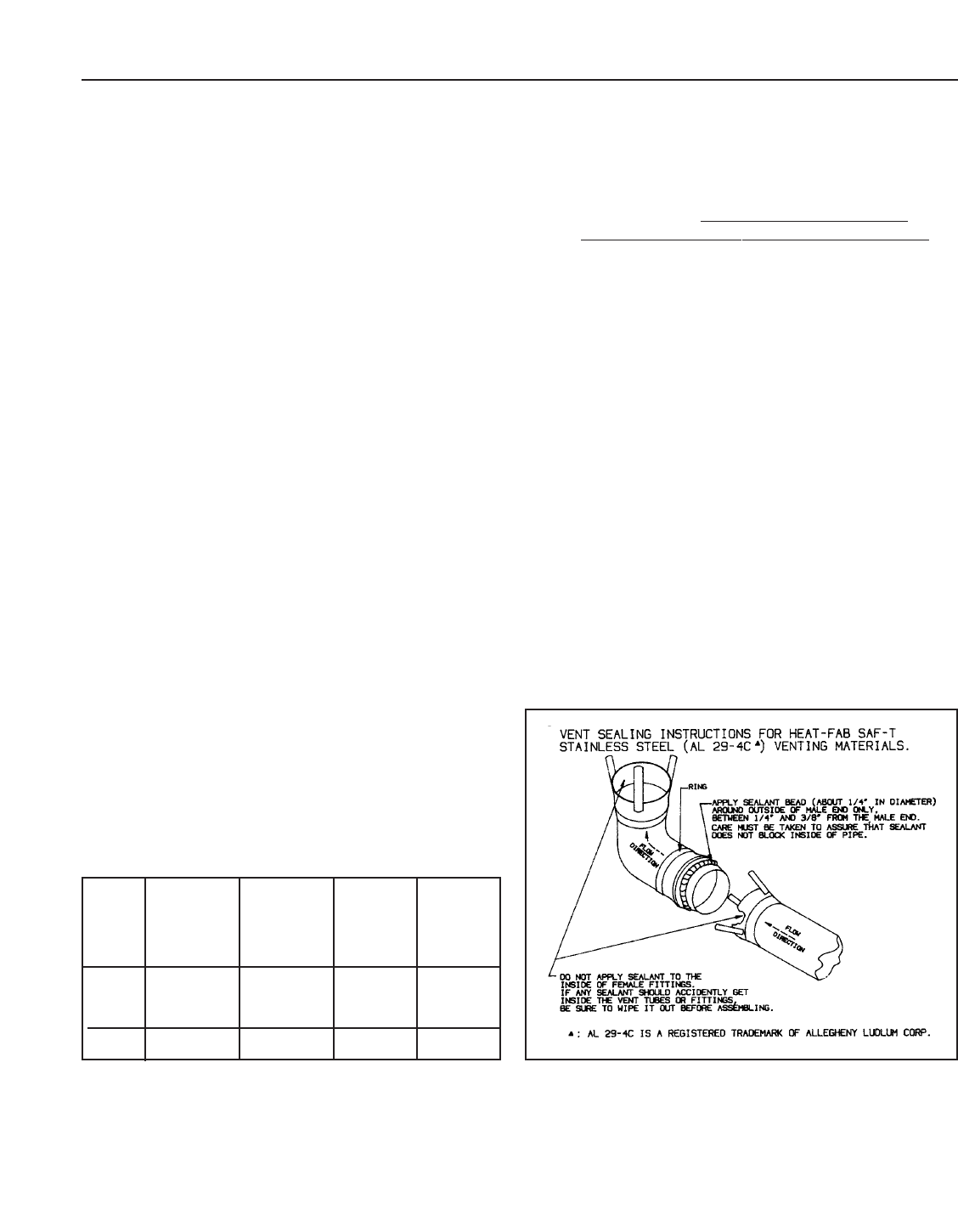

B. When joining the various components of the above list-

e

d vent systems, the man

u

f

a

cturers’

i

nstr

u

ctions

should be closely followed to insure proper sealing.

Use GE-RTV 106 or Dow Corning 732 Sealant for

sealing of pipe and fittings. See figure 4 for proper

a

pplication of vent pipe sealant.

C

. All Victory boilers require a condensate drain and drain

trap.

The horizontal pipe must be sloped TOWARD the con-

densate drain at least 1/4" per 1' of run. The horizontal

portion must also be supported with pipe straps at

intervals no greater than indicated by vent pipe manu-

facturer’s instruction.

Where the vent pipe goes through the outside wall, a

thimble must be used (see Figures 7 and 8).

Heat-Fab pipes and fittings

cannot be cut to length.

Use slip joint connector (Heat-Fab part no. 7324GC) to

adjust pipe lengths dimensions.

Figure 4. Vent Sealing Instructions

(Consult vent manufacturer’s instructions.)

3”

Diameter Venting System Restrictions

Model

Minimum

Length*

Maximum

Equivalent

Length

including

Elbows*

Equiv

alent

Length

of Elbows

Minim

um

No. of

Elbows*

V-33

to 40 ft. 5 ft. 2 ft. 1

V-150

V-180 20 ft. 5 ft. 2 ft. 1

* Vent terminal is in addition to the allowed vent pipe length and elbows.

▲: AL 29-4C is a registered trademark of Allegheny Ludlum Corp.