L

IBERTY II

9

CLEANING AND FILLING A NEW STEAM BOILER

I. BEFORE USING STEAM BOILER

A. Check burner to be certain it is ready for firing. DO NOT FIRE

into an empty boiler.

B. Be prepared to heat raw water to at least 180°F. as soon as it is

introduced into the boiler.This procedure will remove dissolved,

corrosive gases.

C. Provide drain line, with valve, from boiler. Use a bottom tapping.

L

ine and drain must be suitable for handling caustic solution.

D. Check for low water cut-off operation, see section below for

check-out.

II. CLEAN STEAM BOILER SYSTEM.

A. Fill the boiler to water line indicated on the boiler.

B. Follow start-up procedure for burner and operate the boiler with

steam in the entire system for 2 or 3 days to bring oil and dirt

from the system to the boiler.While system is in operation,

maintain the proper water level in the boiler by slowly adding

water to the boiler.

C. Shut down burner, cool down boiler and drain system.

D

. Procedure to dissolve oil and grease in boiler:

1. Fill boiler to proper water line.

2. Prepare a boil-out solution of

sodium hydroxide (caustic

soda) and

tri-sodium phosphate:

NOTE: Use caution in handling chemicals. Caustic soda is

harmful to skin, eyes and clothing.

(a) Proportions: 1 lb. of each chemical per 50 gallons of sys-

tem water.

(b) Stir chemicals into water until dissolved and pour into the

boiler through a top tapping. Replace plug.

3. Start the burner; boil the water for at least 5 hours; shut off

the burner.

E. With CAUTION, drain the boiler solution to a safe location. DO

NO

T LEAVE SOLUTION SITTING IN SYSTEM OVER 2 HOURS.

F

. Wash the water side of the boiler thoroughly using a high pres-

sure w

ater stream.

Fill and drain the boiler several times.

III. TREATING WATER FOR CORROSION CONTROL

(This is not scale control)

A. Prepare a solution of

sodium chromate.

Proportions: 1 lb. per 50 gallons of boiler water.

B. Stir chemical in water until dissolved and pour into boiler

through a top tapping. Replace plug.

IV. FILLING AND VENTING THE STEAM BOILER

A.

Refill the boiler to the indicated w

ater line

.

B. Bring water to boiling temperature, promptly.

C. The boiler is now ready to be put into service or on standby.

BLO

WING OFF A LO

W PRESSURE STEAM BOILER

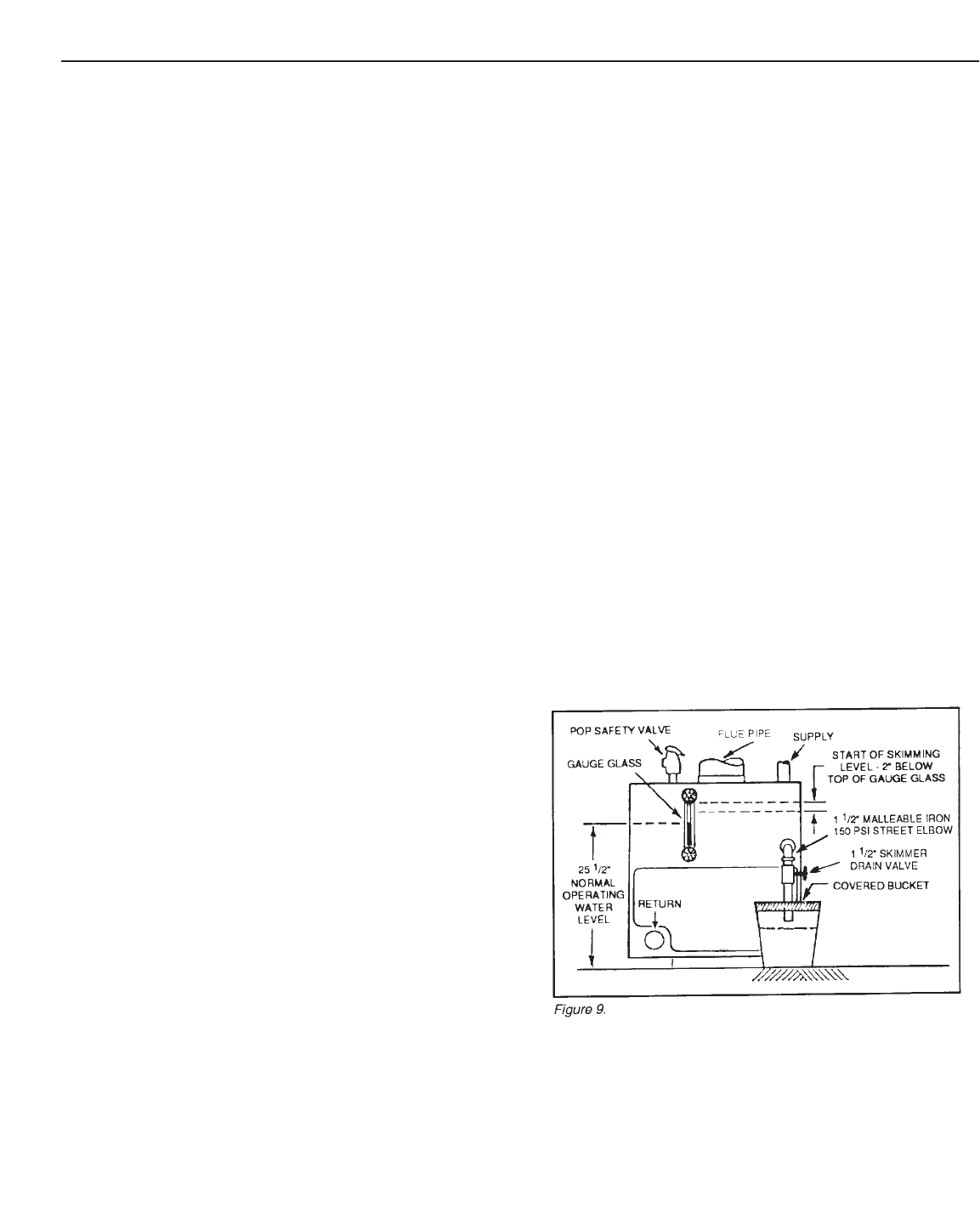

A. A 1-1/2" NPT tapping is provided in the front of the boiler (tapping

no

. 9, figure 1) for use as a surface blow down to provide rapid

skimming of oil and grease which accumulate on the surface of the

w

ater. The boiler should be blown down as outlined below.

B

.

Turn off electrical power supply to boiler. Allow boiler to cool down

and steam pressure to reduce to zero before removing skimmer

tapping plug.

Check for steam pressure by testing the pop safety

valve. Keep your hands and all parts of your body away from the

discharge end of the safety valve. Drain boiler down one to two

inches below skimmer tapping.The water might be hot. Remove

skimmer plug slowly and carefully install a 150 psi malleable iron

1-1/2" NPT street elbow, a 1-1/2" NPT skimmer valve and length of

pipe and place a bucket underneath the open end of the pipe. Cover

bucket with a piece of cloth. (See figure 9)

C. Fill boiler slowly until water level is two inches from top of gauge

glass. (This is the starting water level for skimming only.) Fire boiler to

produce steam. If the system is heavily laden with oil, it may be diffi-

cult to obtain much more than a pound or so of pressure. Set the

pressure control at about 7 psi.

The higher the steam pressure you

can use, the better and faster the cleaning.

D

. As steam develops, open the SKIMMER drain valve with caution to

skim the oil and film from the top of the water. DO NOT open the boil-

er drain valve. Close the skimmer drain valve when the water level

drops to about 5" from the top of the gauge glass.The water may

stop before the level drops to 5" below the top of the glass. Refill boil-

er until water level is again two inches from the top of the gauge

glass.

E. Repeat (D) above until all film is skimmed off and the water settles to

a

normal movement. Add make up fresh water to the boiler as

described in (D) above, during the blow-off operation, to maintain the

proper skimming water level in the vessel. Empty bucket frequently in

order to see the difference in water cleanliness.

F. When surging has stopped and water is clean, and no film can be

seen floating in the bucket, shut off boiler, drain down to level of skim-

mer tapping, remove valve, plug skimmer tapping and refill the boiler

to 24-1/2" water level. After 15 minute operation, readjust level to

normal operating level of 25-1/2" from bottom of boiler (see figure 9).

Check the pop safety valve for proper operation. Check the low water

cut-off operation, see below.

G.

The entire process may have to be repeated over a period of a few

days on extremely fouled systems.

LOW WATER CUT-OFF CHECK-OUT

I. Electronic probe type low water cut-off

If this boiler is factory equipped with an electronic probe type low

water cut-off, operation of cut-off should be checked at least twice a

year as follows:

A. While boiler is running, drain down boiler water slowly through

Boiler Drain Cock shown on page 4, just until light goes on. Boiler

should shut down 10 seconds after light goes on.

B. Be sure that it is the low water cut-off and not the room thermo-

stat, pressure cut-out, or other control that has shut off the burner.

C. Refill the boiler and repeat test.

D

. Refill the boiler and reset controls for normal operation.

II.

Float type low water cut-off

If this boiler is f

actor

y equipped with a McDonnell & Miller float type

low water cut-off, the low water cut-off must be blown down (flushed),

at least once a week.