8

LIBERTY II

VENT PIPING AND DRAFT REGULATOR

A. Vent pipes must be installed having the same diameter as the boiler

outlet. (See page 2)

B. Vent pipes and breeching must be pitched upward a minimum of 1/4"

per foot.

C. Connect vent pipe to the chimney using as few elbows as possible.

D. Horizontal vent connector into the chimney should not be inserted

beyond the inside wall of the chimney.

E

. Install barometric draft regulator on horizontal breeching, near chim-

ney, with hinge horizontal and face vertical. See manufacturer's

instructions packed in carton with barometric draft regulator.

F. If two or more appliances are used on the same chimney, see

CHIMNEY, page 3.

G. Make up all joints with minimum air leaks, secure with sheet metal

screws.

PRECAUTIONS BEFORE STARTING OIL BURNER

Make a positive check of A through F before starting burner:

A. Boiler and system are full of water. All air is vented from system.

See below.

B. All wiring is completed. See pages 11-13.

C. Oil supply is connected to the burner; nozzle is installed correctly; oil

valve is open at tank.

D. Smokepipe is connected to chimney.

E. All combustible materials are cleared away.

F. Combustion air supply is provided. See page 3.

G. Burner settings are adjusted as per pages 14-18 and as shown on

boiler jacket.

H. Main cast-iron door on which burner is mounted is bolted shut and

fiberglass rope seal is making good contact.

* Draft is negative or suction pressure.

ST

AR

T

-UP

(COMB

USTION

TEST INSTR

UMENTS MUST BE USED)

A. Make sure the boiler is installed and wired properly and is full of

water.

B. Open the observation door (on the front, above the burner).

C. Start the oil burner (see burner instructions for bleeding air from oil,

etc.).

IMMEDIATELY, set burner air bands to obtain a bright fire with-

out smoke or oil stain. Set the DRAFT REGULATOR to obtain .02"

o

verfire draft*.Take draft reading through slot in observation door.

D

.

Close the observation door. Allow the burner to fire for at least one

hour total firing time, to bake out the volatile binders in the combus-

tion chamber bef

ore taking final combustion readings.

E. By alternate adjustment of the barometric draft regulator, the burner

air regulation and head regulation devices (whichever apply), set for

a trace of smoke and as close to 13% CO

2

as you can.Then open

the air bands or shutter (whichever apply) an additional 1/8".This

should result in zero smoke with NO raw oil on the smoke paper and

a smooth light-off. DO NOT ATTEMPT TO SET FIRE BY EYE.

Flame retention burners may appear efficient and smoke free from

an inefficient 7% up to an overly high 14% CO

2

. However, a very low

CO

2

can also result in poor ignition and r

a

w (unburned) oil entering

the fire box. At very high CO

2

, any slight decrease in air flow for any

reason will cause incomplete combustion, with high smoke and dry

soot formation in the fire box.

F. If smoke reading is satisfactory, but CO

2

can not be increased to a

satisfactory level (12% or better) or overfire draft of 0.02" W.C. can

not be obtained, chec

k f

or proper sealing betw

een sections, between

burner mounting plate and front section, around burner blast tube

and around flue collector and collar

. If seal is not satisfactory, reseal

with furnace putty or silicone with a temperature rating of at least

400° F. (All safety precautions indicated on material package must

be followed.)

G.

Once burner and draft have been set up, then smoke, CO

2

and stac

k

temperature should be checked and recorded. If smoke is greater than

trace, review the burner instructions; replace the nozzle if necessary.

Normal smoke to be expected at approximately 13% CO

2

is zero to

a trace.

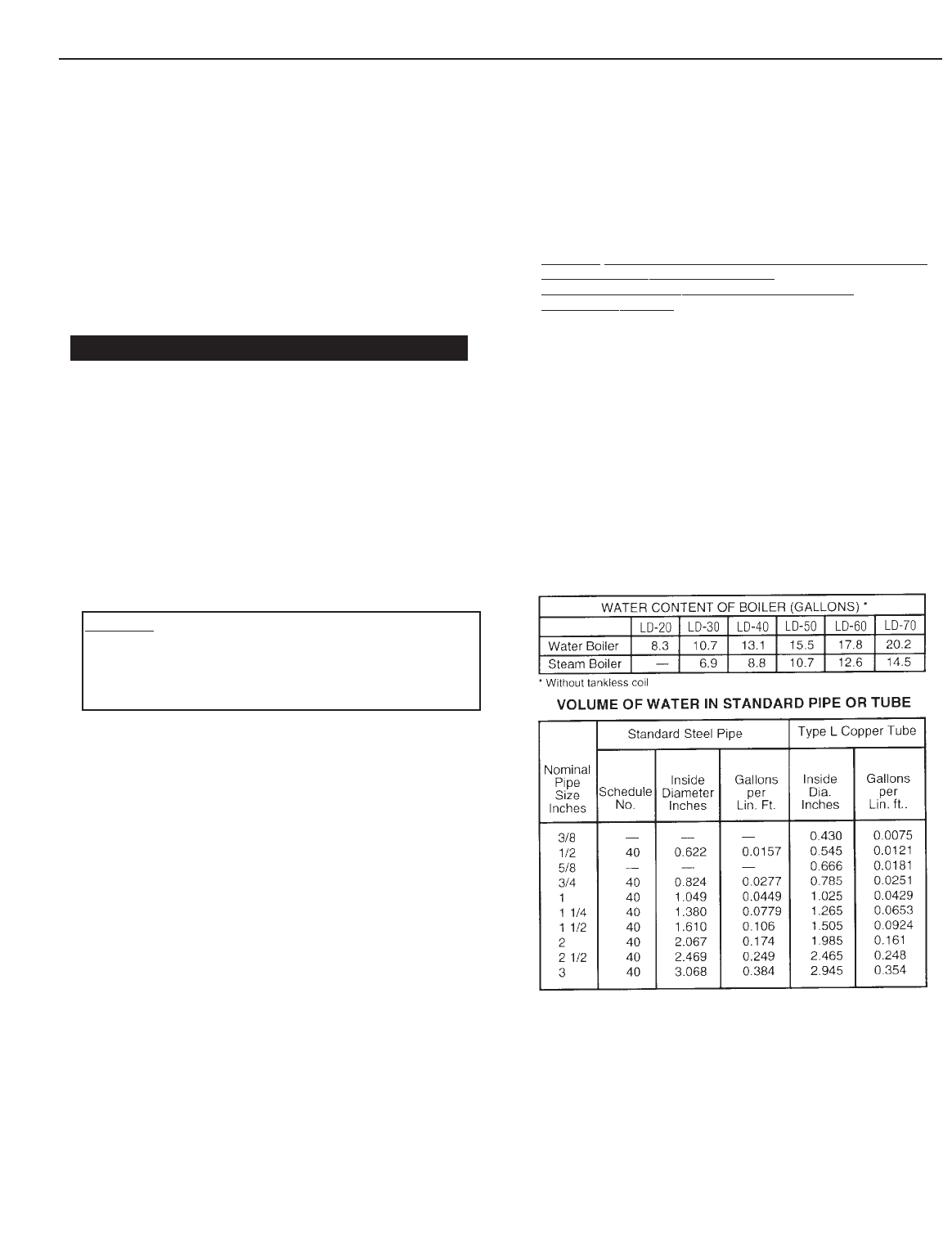

CLEANING AND FILLING A NEW WATER BOILER

I. There are a number of commercial preparations available from your

d

istributor for cleaning and for corrosion protection conditioning the

internal (waterside) surfaces of boilers. Follow the preparation manu-

facturer’s instructions.

DANGER: Use CAUTION when handling chemicals and draining hot

water from a boiler. Scalding water and/or

chemicals can cause permanent injury to the skin, eyes

and respiratory system.

II. Filling and venting the water boiler after cleaning

A. Refill the system with fresh water.

B. Bring water temperature to at least 180° F promptly.

C. Circulate water through entire system.

D

. Vent the system, including the radiation.

E. The boiler is now ready to be put into service or on

standby.

F. If brand name air-control devices are used, venting instructions

furnished with the devices should be followed.

III. Safety check for control system

High limit control test: Set thermostat high enough for boiler water

temperature to reach high limit control setting. When this tempera-

ture is reached, the high limit switch should open, and the burner

should shut off automatically. If the high limit does not operate to

shut off the burner, the high limit or the wiring is faulty. Repair or

replace immediately.

WARNING: NEVER OPERATE any natural draft* boiler

(Liberty II boiler is a natural draft boiler) with zero draft or over-

fire pressure: early failure of the burner, nozzle and chamber is

inevitable if you do. Use a draft gauge, and make sure that

overfire draft* is .02", minimum, during all operating conditions.

OPERATING INSTRUCTIONS