L

IBERTY II

17

NOTE: ELECTRODES ARE PRESET AT THE FACTORY.

REGULA

TION OF THE TURBULATOR AND AIR SHUTTER FOR

PROPER COMBUSTION

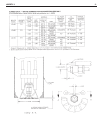

Turbulator Setting

1. Loosen nut, 1, then turn the screw, 2, until the index marker, 3, is

aligned with the correct index number.

2. Retighten the retaining nut, 1.

TURBULATOR SETTINGS - RIELLO 40 SERIES

The numbers on the casting are there to denote the high and low end of

the scale — in all cases the first mark if "Zero".

The air/oil r

atio depends on accur

ate setting of the turb

ulator disc.

Be careful when making this adjustment as an incorrect setting will result

in an unsatisfactory installation. See figures 10A and 10B.

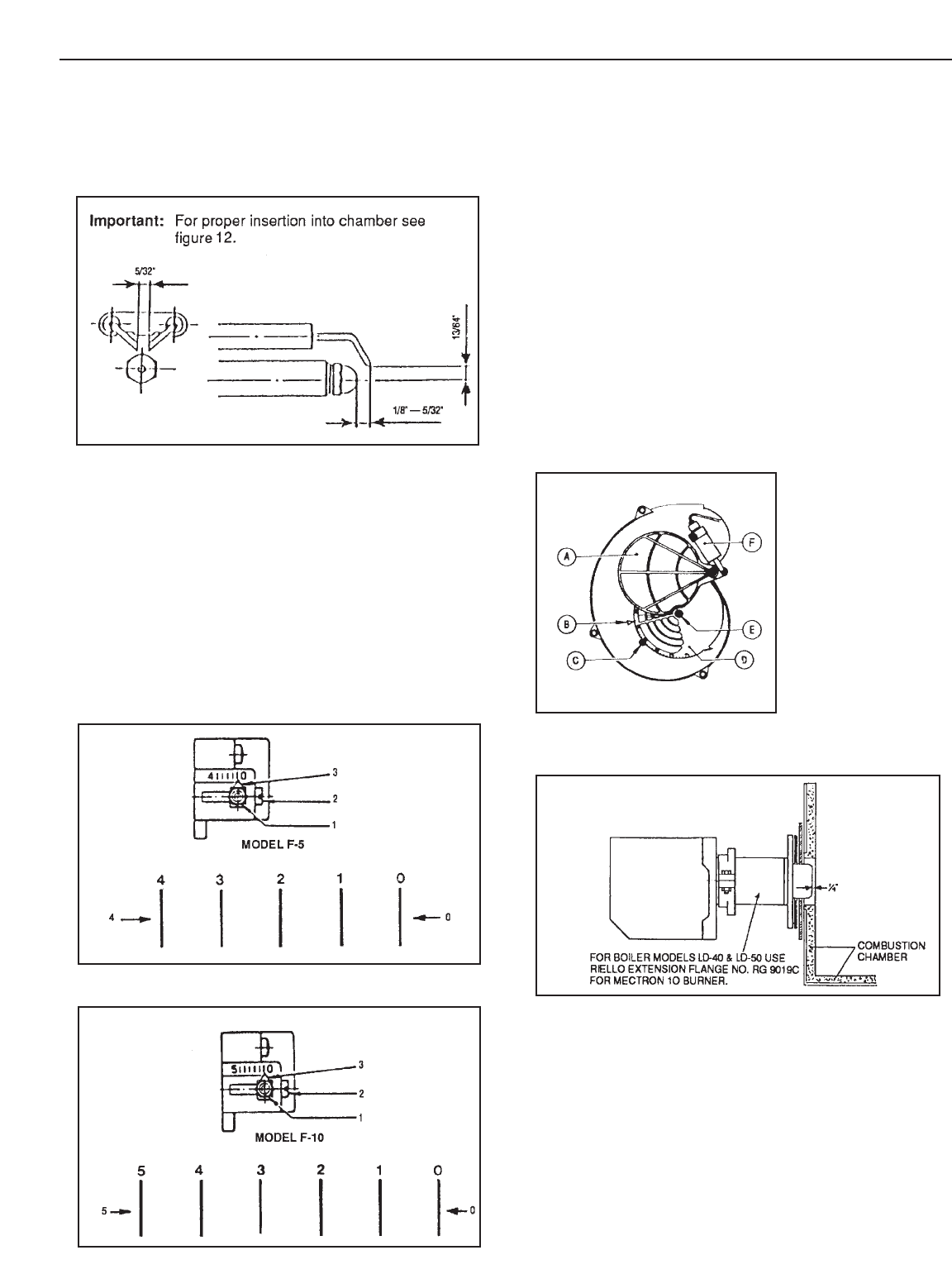

SETTING THE AIR ADJUSTMENT PLATE (See figure 11)

1. The hydraulic AIR SHUTTER (A) is operated by the HYDRAULIC

JACK (F), assuring complete opening of the combustion air intake.

Regulation of the combustion air flow is made by adjustment of the

manual AIR ADJUSTMENT PLATE (D) after loosening the FIXING

SCREWS (C and E). The initial setting of the air adjustment plate

should be made according to page 16.

2. The proper number on the manual AIR ADJUSTMENT PLATE (D)

should line up with the SETTING INDICATOR (B) on the fan housing

cover. Once set, the air adjustment plate should be secured in place

by tightening SCREWS C and E. Manually open and release the

hydraulic air shutter to ensure it has free movement.

3. The final position of the air adjustment plate will vary on each instal-

lation. Use instruments to establish the proper settings for maximum

CO

2

and a smoke reading of zero.

NOTE: Variations in flue gas, smoke, CO

2

and temperature readings

may be experienced when the burner cover is put in place.

Therefore, the burner cover

must be in place when making

the final combustion instrument readings, to ensure proper

test results.

FIgure 9B

FIgure 10A

FIgure 10B

FIgure 11

FIgure 12

MODEL F-10

ELECTRODE SETTING

FOR PROPER INSERTION INTO COMBUSTION CHAMBER

B

URNER DATA – RIELLO (continued)