Bobcat Models B-120A and B-200A

4

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the National Fuel Gas Code, ANSI Z223.1-

latest edition.

This installation must also conform to the additional require-

m

ents in this Slant/Fin Instruction Book.

BOILER LOCATION

Provide a level, solid foundation or vertical wall for the boiler.

Location should be as near as possible to chimney or outside

wall so that the flue pipe from boiler is short and direct. (See

paragraph heading “Vent Termination Location and Clear-

ance” on page 9.) The location should also be such that all

boiler components are protected from water (dripping, spray-

ing, rain, etc.) during appliance operation and service (circu-

lator replacement, control replacement, etc.).

WARNING

LIQUEFIED PETROLEUM (L.P.) PROPANE GAS-FIRED

BOILER LOCATION

REQUIRES SPECIAL ATTENTION

Liquefied Petroleum (L.P.) propane gas is

heavier than air.

Therefore, propane boilers, piping, valves should NOT be

installed in locations where propane leaking from defective

equipment and piping will "pool" in a basement or other

space below the leak.

A spark or flame from the boiler or other source may ignite

the accumulated propane gas causing an explosion or fire.

Provide a level, solid foundation for the boiler. Location

should be as near the chimney as possible so that the flue

pipe from boiler to chimney is short and direct.

The UNIFORM MECHANICAL CODE may be in effect in

your geographic area.

The following precautions are cited by the 1994 UNIFORM

MECHANICAL CODE, section 304.6:

"LPG Appliances. Liquefied petroleum gas-burning

appliances shall not be installed in a pit, basement or

similar location where heavier-than-air-gas might collect.

Appliances so fueled shall not be installed in an abo

ve-

grade under-floor space or basement unless such loca-

tion is pro

vided with an approv

ed means for remo

val of

unbur

ned gas."

Consult Chapter 5 of the 1994 UNIFORM MECHANICAL

CODE f

or design criter

ia of the "approv

ed" means f

or

remov

al of unbur

ned gas

.

BOILER FOUNDA

TION

A. Provide a solid, level foundation or vertical wall capable of

suppor

ting the w

eight of the boiler filled with w

ater

, and

e

xtending at least 2" past the jac

ket on all sides. See

dimensions of boilers, page 2. See also figure 4a & 4b for

mounting the boiler on the wall.

B

.

Boiler can be installed on both comb

ustib

le and

non-comb

ustib

le floors, but must NOT be installed on or

above carpeting.

C. If boiler is to be located over buried conduit containing

electric wires or telephone cables, consult local codes or

the National Board of Fire Underwr

iters f

or specific

requirements.

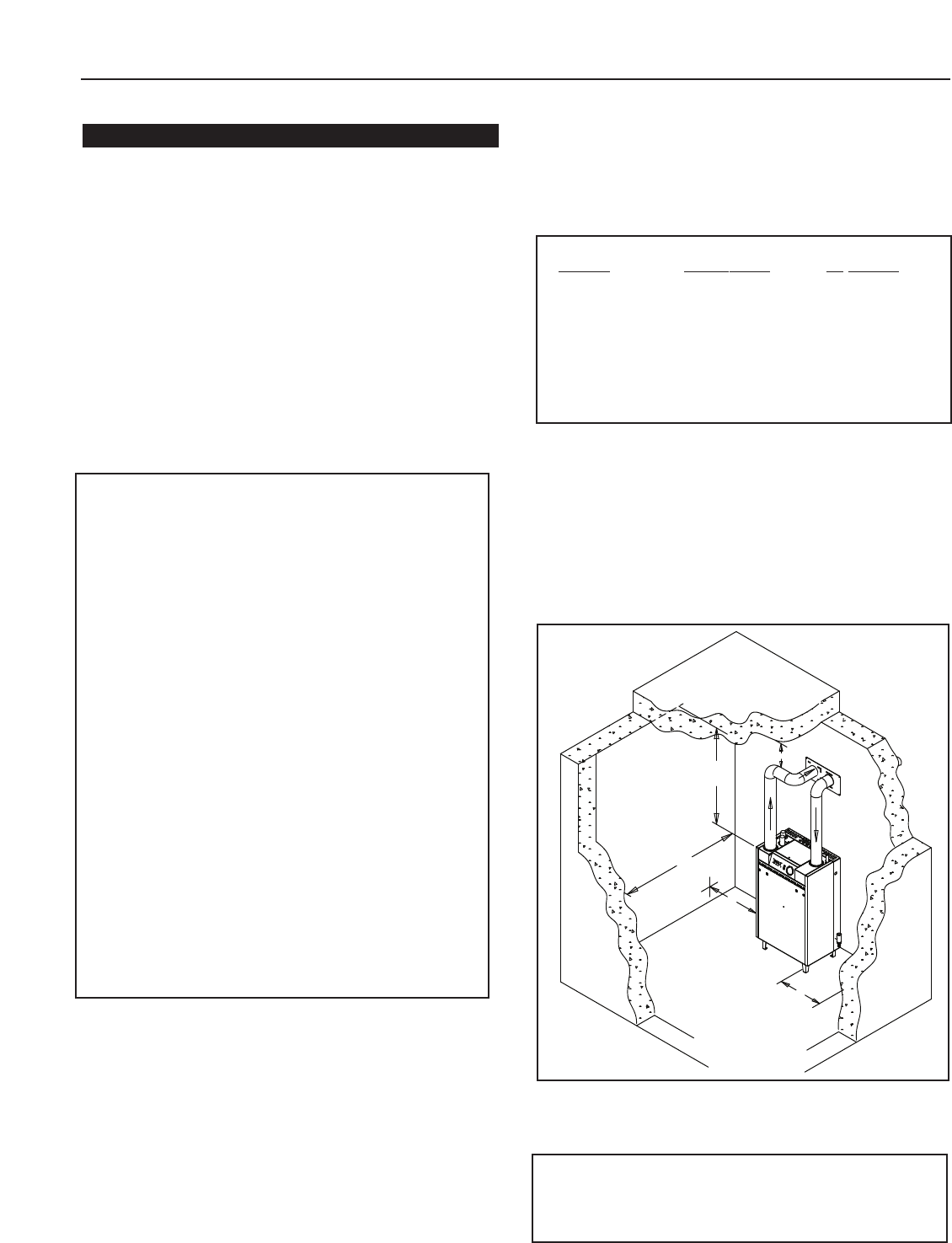

MINIMUM CLEARANCES FROM COMBUSTIBLE

CONSTRUCTIONS

A

. Minimum clearances to the exterior surfaces of the boiler

shall be as follows:

M

INIMUM ALCOVE AND CLOSET CLEARANCE

F

or Combustible Recommended

Surf

ace Construction for Service

F

ront 6" 18"

Rear 0" 0"

Left Side 2" 8"

Right Side 2" 8"

T

op 3" 18"

Flue Connector:

Enclosed — 2" 6"

Uninclosed — 1" 6"

B. Provide accessibility clearance of 8" on sides requiring

servicing and 18" on sides used for passage.

C. All minimum clearances shown above must be met. This

may result in increased values of some minimum clear-

ances in order to maintain the minimum clearances of

others.

D. Clearance from hot water pipes shall be 1 inch**.

** A

t points where hot water pipes emerge from a floor,

wall or ceiling,

the clearance at the opening through the finished floor boards or wall

or ceiling boards may be not less than 1/2 inch.Each such opening

shall be covered with a plate of uncombustible material.

SAFETY

KEEP

THE BOILER AREA CLEAR AND FREE FR

OM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

Figure 3. Bobcat boiler min. clearances for combustible

construction.

INSTALLATION REQUIREMENTS

: 2" FOR ENCLOSED

*

1"

3"

6"

*

2"

2"