Bobcat Models B-120A and B-200A

19

A

t 30 ft. length of pipe, match required capacity from table on

t

his page (choose higher capacity, in this case is 152 cu. ft. per

hour). Required pipe size is

3

⁄4".

I

mproper gas pipe sizing will result in flame outages, insuffi-

cient heat and other installation difficulties. For more informa-

tion and also if other appliances are to be attached to the

piping system, see Appendix C of National Fuel Gas Code

ANSI Z223.1-latest edition.

C. The boiler and its gas connection must be leak tested

before replacing the boiler in operation. Use liquid soap

solution for all gas leak testing. DO NOT use open flame.

This boiler and it’s individual shutoff valve must be

disconnected from the gas supply piping system during and

pressure testing of that system at test pressures in excess

of

1

⁄2 PSIG.This boiler must be isolated from the gas supply

piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than

1

⁄2 PSIG.

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap is integrally

provided, as illustrated on page 3.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for

the type of gas used. Gas supply pressure should never be

less than minimum or more than maximum pressure when

the boiler or any other appliance is turned on or off.

ELECTRICAL WIRING

All field wiring to the boiler is connected to the 2 sets of

ter

minal str

ips, located under the jacket top panel.

(See Figure 2, on page 3)

DANGER: Before wiring always turn off electric power supply.

Otherwise, shock or death can result.

1. Power Supply

A separately fused circuit is recommended. Use standard

15 Amp. fuse or breaker and 14 gage conductors in BX

cab

le or conduit.

Provide disconnect means and overload protection as

required.

See boiler wir

ing diag

r

am (Figure 16a) boiler

control (Figure16b) and ladder diagram (Figure 16c).

B

oiler must be electrically grounded in accordance with the

r

equirements of the authority having jurisdiction, or, in the

absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70-latest edition.

Proper polarity is critical for the power supply connections.

Reversed polarity will cause system lockout. Proper ground-

ing is critical for boiler operation, connect the ground wire to

the green ground screw next to the line voltage terminal

s

trip.

2. Circulator(s)

A set of terminals are provided for the boiler (primary loop)

circulator. Only wire this circulator to these terminals,

additional (secondary loop) circulators for space heating

require the use of relays and a separate power source.

For multiple zoning, either zone valves or circulators maybe

used.

For zone valve system (See Figure 17a).

For pump zoning system (See Figure 17b and 17c).

DO NOT use boiler transformer to power external

accessories like zone valve and relays, overload and/or

burned out transformer and boiler malfunction can result.

Use separate transformer to power such components.

A second set of terminals are provided for the domestic hot

water tank circulator (if used).The primary loop circulator is

always de-energized when the DHW tank circulator is

energized, for priority.

3. SPACE HEATING THERMOSTAT(S)

Install thermostat on an inside wall and away from any heat

sources, sunshine and drafts. A set of terminals are provid-

ed for connection of 24 volt style thermostats, relays or zone

valve end switches (isolated contacts). (See wiring diagram

Figure 16a).

Thermostat heat anticipator: For a non-zoned system set

thermostat heat anticipator to 0.1 Amps, for zoned system

set to match power requirements of zone valves or relays.

Refer to man

ufacturer’

s instructions and specifications. Also

see instr

uctions with ther

mostat.

4. DOMESTIC HOT WATER TANK THERMOSTAT

A set of terminals are provided for connection of the DHW

tank thermostat (if used). (See wiring diagram Figure 16a).

5. OUTDOOR AIR SENSOR

A set of terminals are provided for connection of an outdoor

air sensor (if this method is used). (See wir

ing diagr

am

Figure 16a).

The outdoor air sensor m

ust be a 12k ohm type

.

Mount on

an outside wall, shielded from direct sunlight or flow of heat

or cooling form other sources. See instructions provided

with sensor.

6. LOW WATER CUTOFF

A set of ter

minals are pro

vided f

or connection of a LWCO. If

this de

vice is used, remove the factory installed jumper from

these terminals. (See wiring diagram Figure 16a).

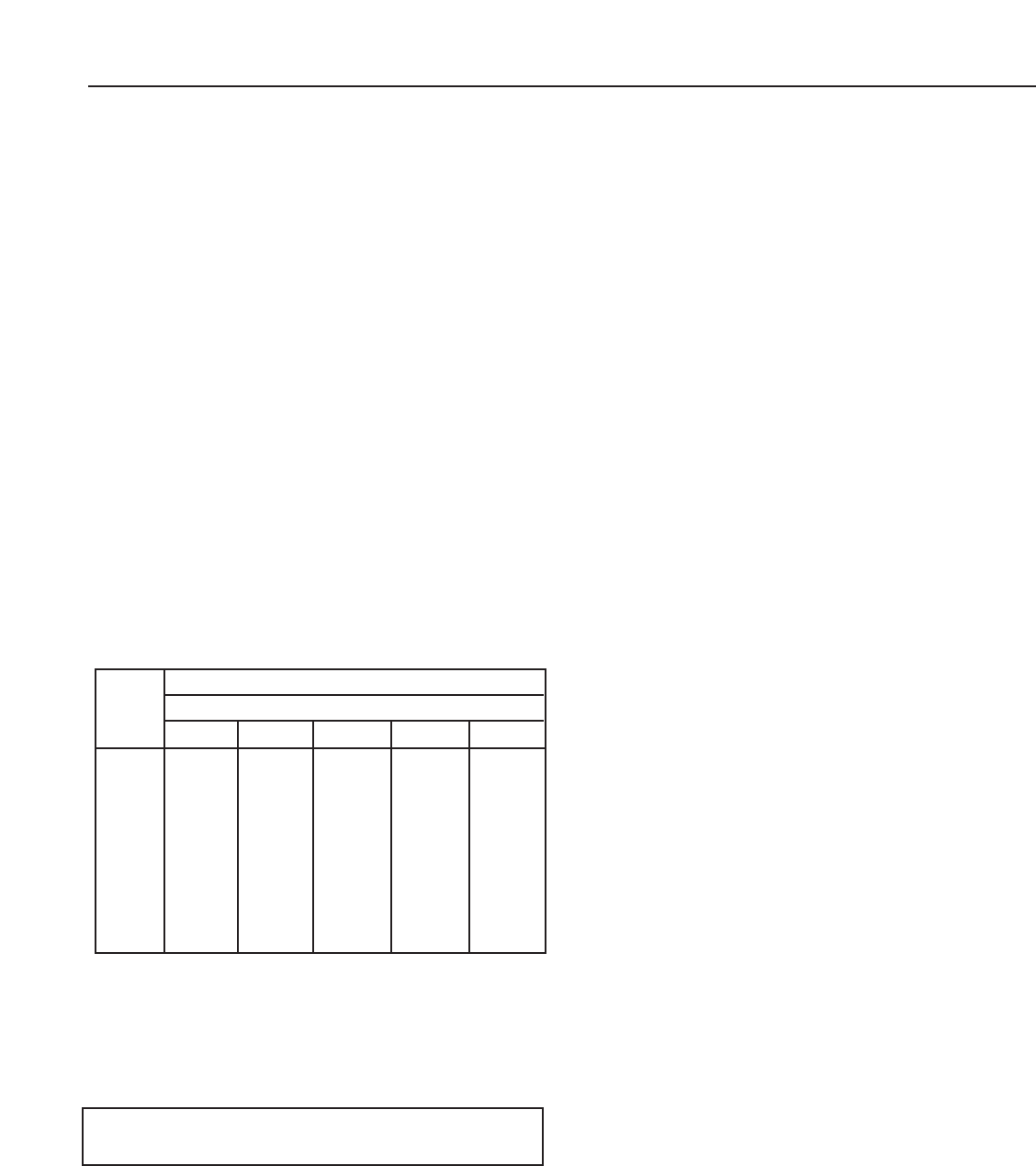

Length

of pipe

in Feet

1/2

3

/4 11

1

/4

1

1

/2

Gas Flow In piping -- cu. ft. per hr.

Iron Pipe Size (IPS) — inches

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 890

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

At pressure drop of 0.3 in. w

ater

, specific gr

a

vity = 0.6.