Troubleshooting & Repair,

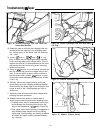

Figure 47. Reconnect Idler Pulley Tension Spring

9. Lift the drive belt over the edge of the drive pulley

and engage the pulley, beveled edge in, and slide

the drive belt pulley plate and drive shaft into

position. Install the two hex head screws and lock

washers removed earlier, and tighten securely

(Figure 46).

10.

Reach around to the back of the unit, and making

sure the drive belt is fully engaged in all pulleys,

reconnect the tension spring to the threaded stud to

maintain tension on the drive belt (Figure 47).

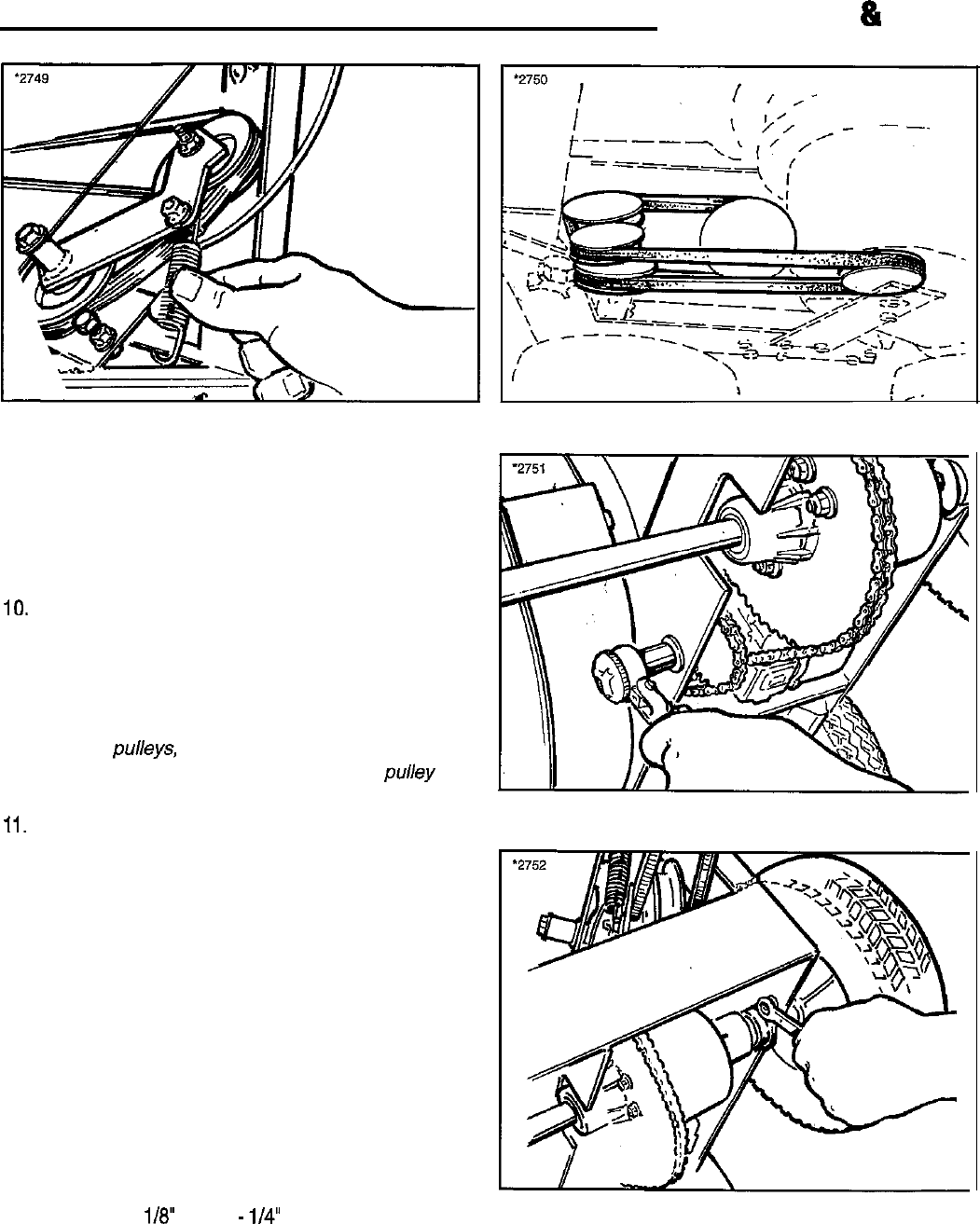

NOTE: The beveled edge of the drive belt should be

engaged against the transmission pulley and the two

pivoting idler

pu//eys,

and the flat side of the drive be/t

should be engaged against the larger, angled pu//ey with

the wider groove (Figure 48).

ii.

Reassemble covers to unit in reverse sequence of

disassembly.

DRIVE CHAINS

General

The drive chains may be accessed by tilting the back of

the unit up, and supporting it securely to prevent the unit

from falling backward during service. Drive chain

access is from under the unit, and extreme care must be

used when checking, tightening, or replacing drive

chains.

Do not tip the unit for service if the fuel tank is

full. Drain the fuel tank carefully, and follow all precau-

tions for handling gasoline when performing this step.

Drive chain tension may be adjusted by moving

adjustable sprocket mounting brackets (front chain) or

the drive axle (rear chain) to achieve desired tightness.

Chains will have

i/8” (front)

-

l/4” (rear) of flex between

sprockets when properly tensioned.

Figure 48. Drive Belt Installed Position On Pulleys

Figure 49. Loosen Hex Nut To Adjust Tension On

Front Chain

Figure 50. Loosen Hex Nut To Adjust Tension On

Right Axle Mounting Bracket

33