Troubleshooting & Repair

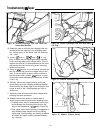

Figure 35. Remove Discharge Tube Hex Head Cap

Screw And Hex Nut

13. Rotate the rotor to move the first chipping knife into

position at the rear opening in the shredding cham-

ber. Pulling slowly on the starter rope will make the

rotor rotate.

14. Insert a

l/Z”

thick x 1 l/2”

-

2”

wide x IO

-

12” long

piece of wood into the chipping/shredding chamber

under the sharp edge of the chipper knife. This will

support the knife as it is disassembled from the rotor,

and prevent the rotor from turning as the mounting

screws are removed.

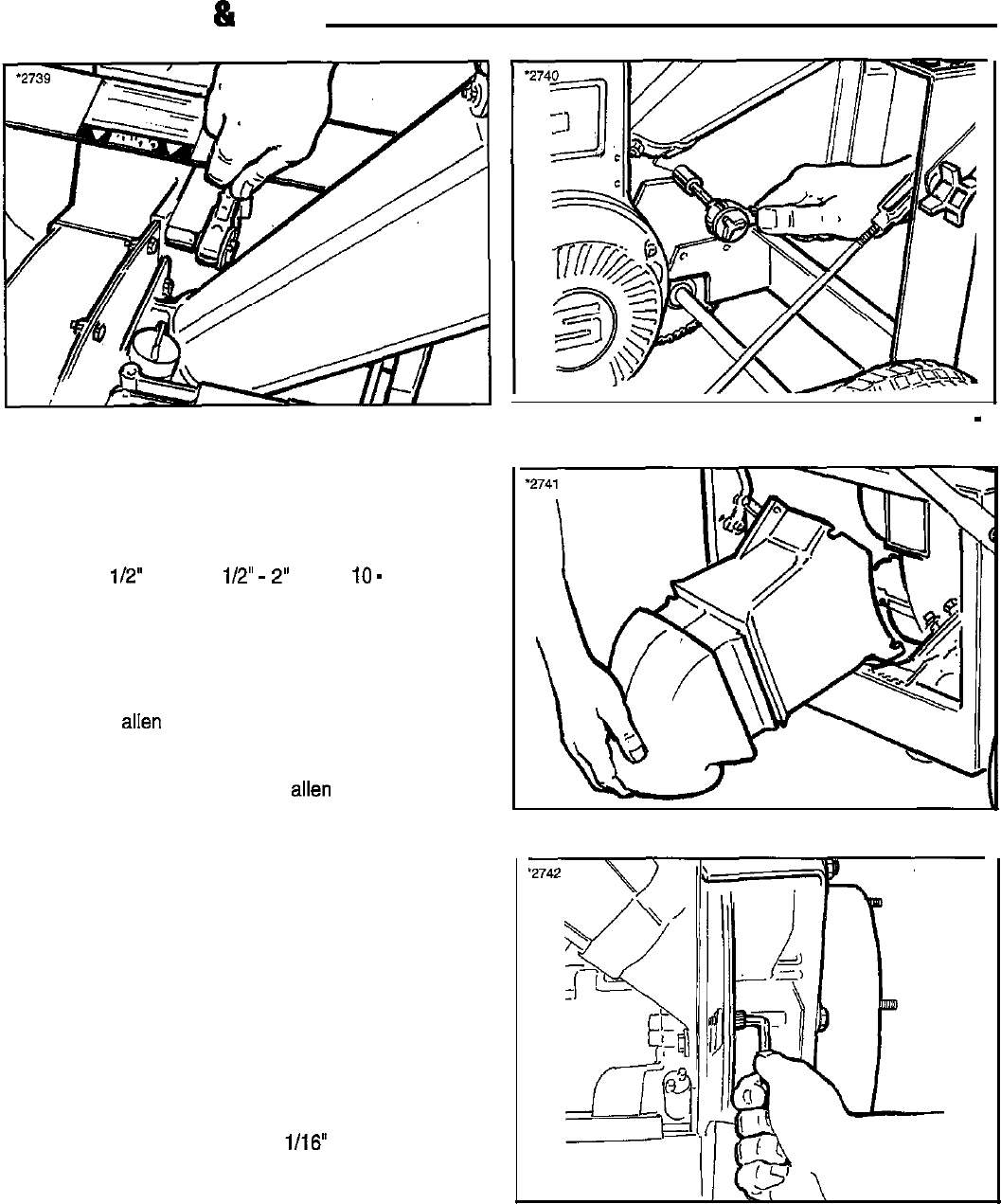

15. Using an

allen

wrench or hex bit socket, unscrew the

two cap screws that secure the chipper knife to the

rotor. It may be helpful to clean out the sockets on

the cap screws with a smaller

allen

wrench or piece

of bent wire before attempting to remove the screws

(Figure 38).

16. Carefully remove the chipper knife by pulling the

board slowly out of the chipping/shredding chamber.

Avoid touching the sharp edge of the blade with bare

hands as even a “dull” chipping edge can inflict a

serious cut.

17. Rotate the rotor and remove the other chipper knife

following the same procedure.

18. Sharpen both knives equally or replace both to

ensure proper balancing and correct chipping action.

l Chipping knives may be resharpened until the dis-

tance between the mounting holes and the top

edge of the blade bevel is

l/16” apart (Figure 39).

l Slow speed water-cooled grinding is suggested to

help maintain blade temper and a long lasting

Figure 36. Loosen Discharge Tube Hex Head Nuts

-

Left Side

Figure 37. Remove Discharge Tube

sharp edge. Rapid grinding and heating of blades

will soften the edges, making repeated sharpen-

Figure 36. Remove Chipper Knives

ing necessary.

30