Troubleshooting & Repair

ii

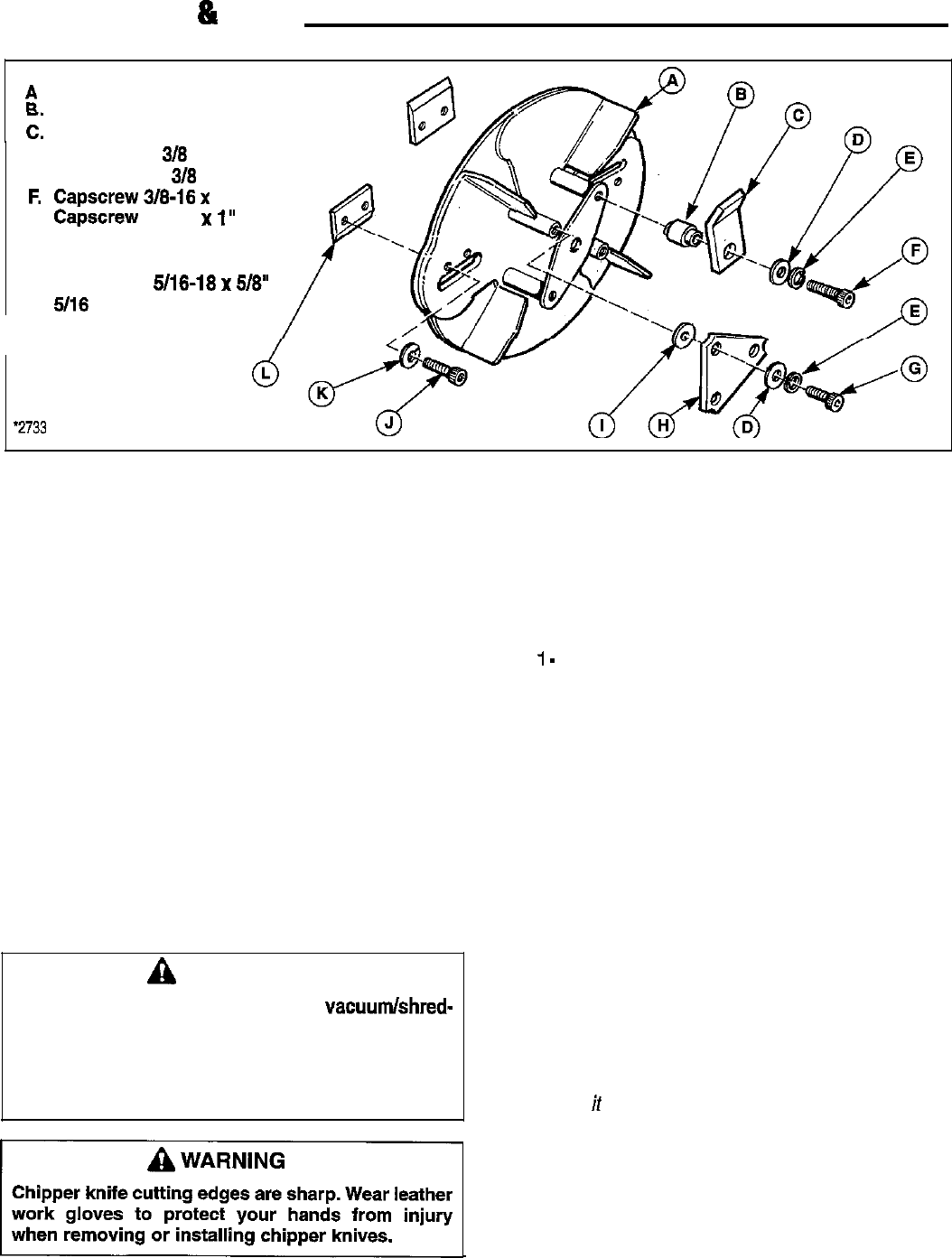

c:

D.

E.

F.

G.

H.

I.

J.

K.

L.

‘2733

Rotor

Spacer

J Hammer (2)

Flat Washer

318

Lock Washer

310

Capscrew

318-16

x

2”

Capscrew 318-f 6 x 1”

Triangular Hammer (2)

Bushing, Flanged

Cap Screw 5/16-18

x

5/8”

5116

Lock Washer

Chipper Knife (2)

Figure 29. Proper Hammer Assembly

15. Rotate the rotor to move the next hammer into

position for servicing, and repeat step 14.

16. If chipping knives are to be inspected or serviced, go

to the next section for instructions. If service is to be

performed on shredding hammers only, proceed to

the next step.

17. Reassemble the unit in the reverse sequence used

to disassemble it in the preceding steps.

18. Check all hardware for tightness and correct

assembly before attempting to start the unit. Do not

attempt to start the unit if extra hardware or other

parts are left over after reassembly has been

completed. Identify the correct assembly location for

any remaining parts using the illustrations in the

manual, and install as required.

19. Start the unit and listen for unusual noise or vibra-

tion. Stop the unit immediately if any problems are

apparent, and check the assembly of all parts for

proper positioning before starting the unit again.

A

WARNING

Never use the unit for chipping or

vacuumlshred-

ding unless the discharge bag is attached, or the

deflector elbow has been installed.

.

Material could be ejected out of the discharge

chute with great force, injuring you or bystanders.

CHIPPING KNIVES

Chipping knives should be resharpened or replaced

when tree limbs and branches begin to require extra

force to feed into the chipper block.

To inspect and service the chipping knives, follow these

steps: (If hammer service has just been performed, skip

steps

1

-

2).

1. Turn the engine off, allow the rotor to stop

completely, and disconnect the spark plug wire.

2. Remove the top and right side covers as shown in

the preceding hammer replacement section.

3. Remove the discharge bag.

4. Remove the panel fastener and slotted hex head

screws from the left cover (Figure 29).

5. Remove the left cover (Figure 30).

6. Remove the panel fasteners from the rear panel

(Figure 31).

7. Slide the rear panel down, and tilt the rear of the unit

up slightly to allow the panel to slide free of the

grooves in the discharge tube (Figure 33).

7a. Electric start units only: Disconnect and remove the

battery.

NOTE: Always remove the negative terminal cab/e first

and reinstall if last to reduce the risk of sparking and

short-circuiting the battery if metal-to-metal contact is

““““““1

made between the positive terminal and the unit’s frame.

Chipper knife cutting edges are sharp. Wear leather

7b. 8 H.P. units only: Remove top screws securing the

work gloves to protect your hands from injury

fuel tank to the frame, and carefully move fuel tank

when removing or installing chipper knives.

forward and rest it on drive belt while chipper knife

service is being performed.

26