5061 Brooks St. Montclair, CA 91763

800-527-4790 Fax 1-909-399-3357

www.sierraproductsinc.com

P/N EF3801 4001 Sensor replacment 4/04

2 6

EF3801/4001 V1 Feed System

Service or Repair Instruction

Figure 1

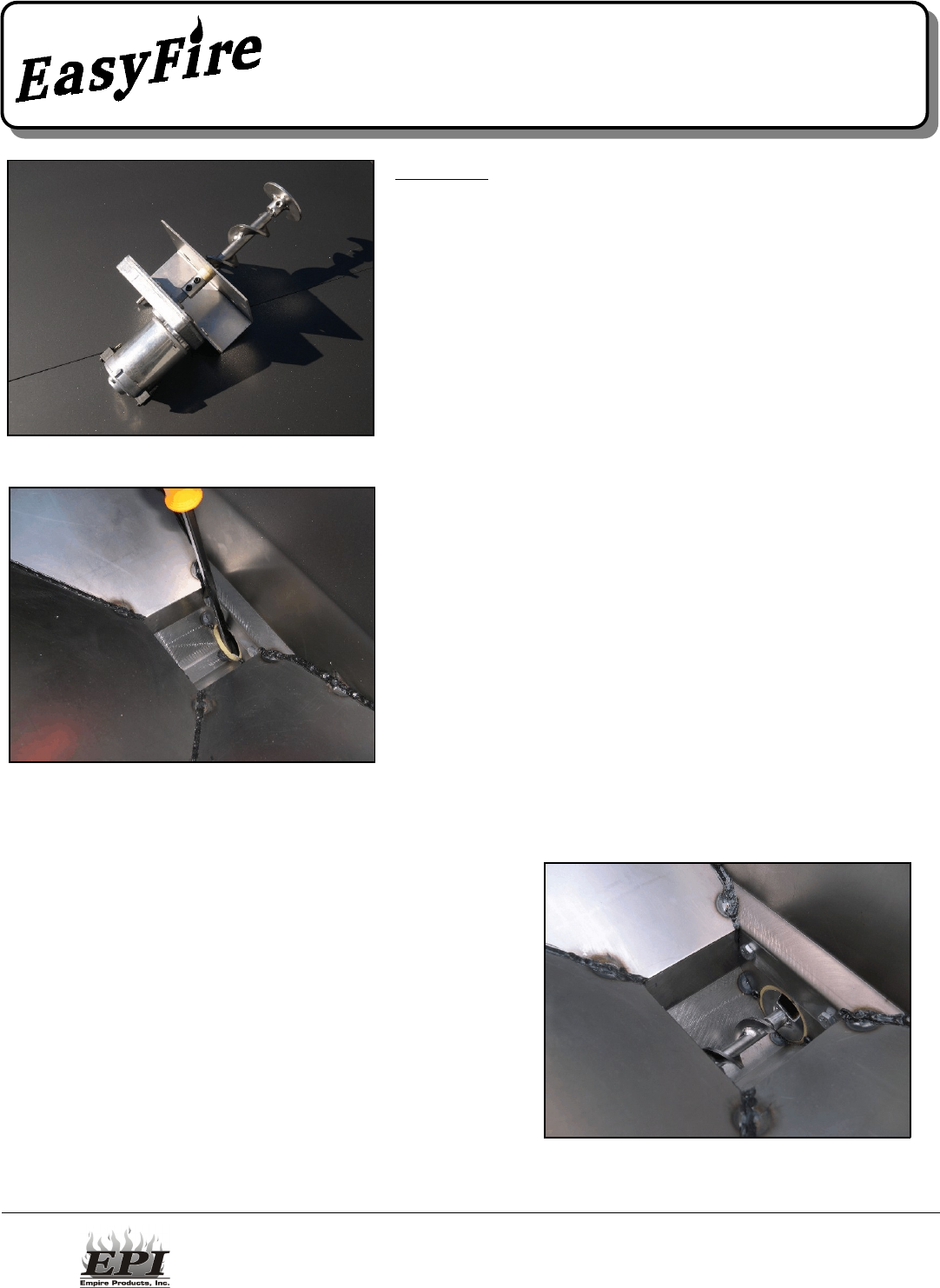

Figure 3

OVERVIEW

The EasyFire feed system consists of four main components, feed

motor and mounting plate, feed auger shaft, feed disk, and feed disk

bushing (Figure 1). These components are designed to provide

thousands of hours of service and rarely require service or

replacement. Operation of feed system is controlled by the main

control board based on the stoves temperature and heat setting. Unlike

other pellet stoves, the system operates by increasing and decreasing

the speed of the auger and disk. Pellets are pushed forward toward the

disk and as the disk rotates clockwise (from front of stove) allows the

pellets to be feed into the shoot. Three feed disk sizes are available

with the standard = 1, medium = 2, and large = 3. #3 feed disks are for

large or long pellets only. If overfeeding or under-feeding is a problem

and adjusting the feed trim will not compensate, changing the feed disk

is advised.

Removing and Replacing the Feed Assembly: The feed assembly

and gear motor is accessed by removing the rear inspection panel for

both the heater and insert. Remove the four or six #8 screws

attaching the inspection cover and remove cover. Remove all pellets

from hopper and feed disk area inside unit. Locate feed motor and

unplug wire harness connections (note location of red banded wire on

motor to assure proper rotation of motor). Remove wing nuts (or #10

nuts on some units) attaching feed motor bracket to rear of feed shoot.

Gently remove feed assembly by pulling toward the rear of unit. The

feed shaft maybe removed by loosening the allen screws holding the

shaft coupler. Remove the two #8 phillips screws holding the feed

motor bracket to the gear motor. Reverse process to install feed

motor assembly.

Bushing replacement: Disk bushing may be replaced by removing 2-

#8 retaining screws and carefully prying with a large flat blade screw

driver from inside hopper (Figure 2). To re-install bushing clean area

with thinner or alcohol and apply a small amount of red lock-tight to bushing. Align with plate and carefully pry back with

screw driver. Straighten bushing and install retaining screws.

Shaft or Disk Replacement: The feed disk and shaft depth are set

at the factory to allow the feed disk to ride fully in the feed disk

bushing. When replacing either component, make sure the installed

disk ride toward the rear of the disk (Figure 3) and does not extend

to far forward. If the disk is set to far forward it may jamb causing

the shaft to bend or break. Assemble the new components onto the

motor drive loosely then install into stove. Carefully position disk and

mark or tighten disk onto shaft. Remove disk and motor assembly

from stove and tighten with 1/8" allen wrench.

NOTE: WHEN ASSEMBLING THE SHAFT AND COUPLER,

ALWAYS USE A SMALL AMOUNT OF LOCK TIGHT (RED) ON

ALLEN SET SCREWS. AFTER THE ASSEMBLY HAS BEEN

INSTALLED THE FEED DISK MUST RIDE IN THE CENTER OF

THE FEED BUSHING.