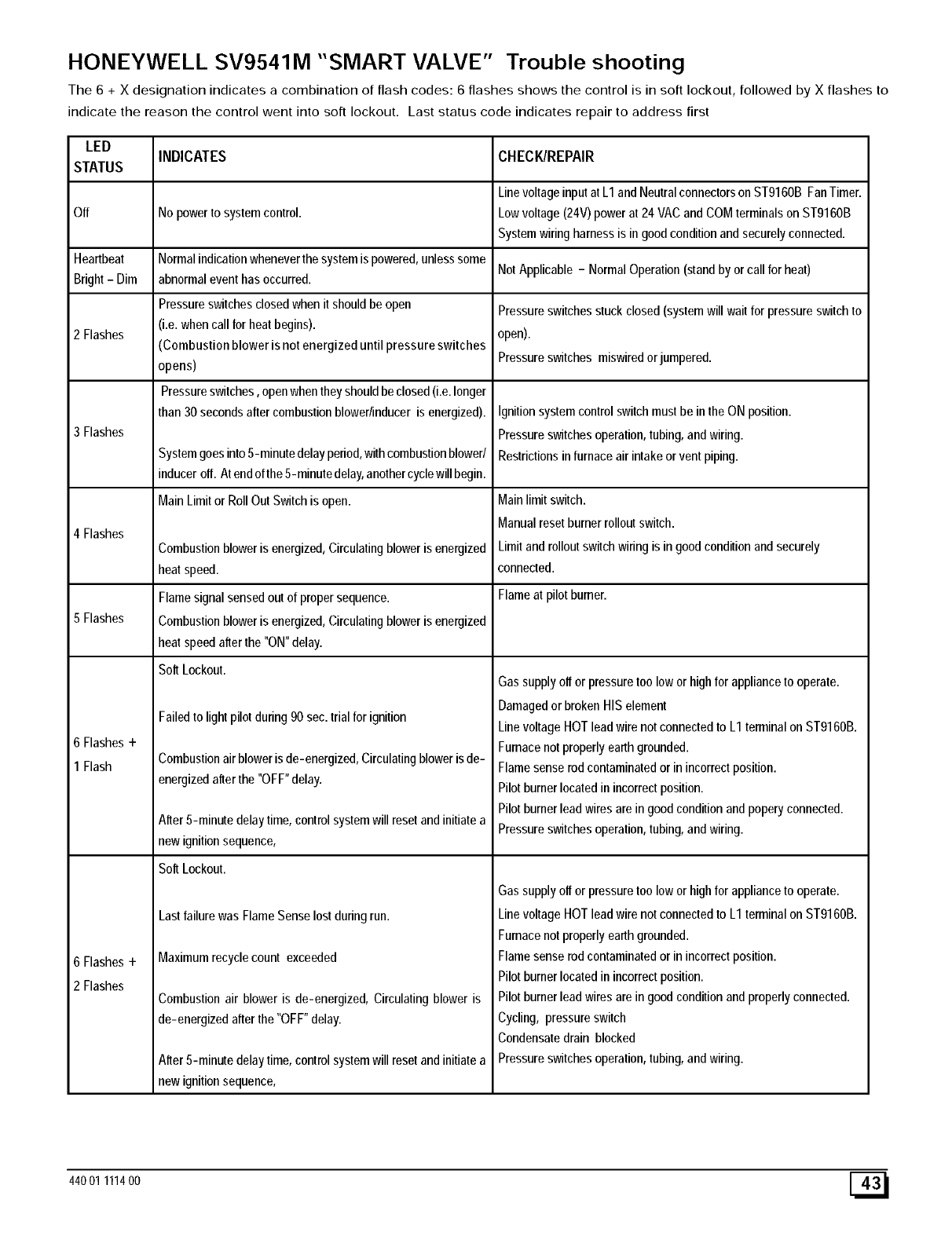

HONEYWELL SV9541M "SMART VALVE" Trouble shooting

The 6 + X designation indicates a combination of flash codes: 6 flashes shows the control is in soft lockout, followed by X flashes to

indicate the reason the control went into soft lockout. Last status code indicates repair to address first

LED

INDICATES CHECK/REPAIR

STATUS

Line voltageinput at L1 and Neutral connectors on ST9160B FanTimer.

Off No power to system control. Low voltage (24V) power at 24 VAC and COM terminals on ST9160B

System wiring harness is in good condition and securely connected.

Heartbeat Normal indication whenever the system ispowered, unless some

Bright - Dim abnormal event has occurred. Net Applicable - Normal Operation (stand by or call for heat)

Pressure switches closed when it should be open Pressure switches stuck closed (system will wait for pressure switch to

2 Flashes (i.e. when call for heat begins), open).

(Combustion blower is not energized until pressure switches

opens) Pressure switches miswired erjumpered.

Pressure switches, openwhen they should be closed (i.e.longer

than 30 seconds after combustion blower/inducer is energized).

3 Flashes

4 Flashes

5 Flashes

6 Flashes+

1Flash

6 Flashes+

2 Flashes

System goes into5-minute delay period,with combustion blower/

inducer off. Atend ofthe 5-minute delay, another cycle will begin.

Main Limit or Roll Out Switch is open.

Combustion blower is energized, Circulating blower is energized

heat speed.

Flame signal sensed out of proper sequence.

Combustion blower is energized, Circulating blower is energized

heat speed after the "ON" delay.

Soft Lockout.

Failed to light pilot during 90 sec. trial for ignition

Combustion air blower isde-energized, Circulating blower isde-

energized after the "OFF" delay.

After 5-minute delay time, control system will reset and initiate a

new ignition sequence,

SoftLockout.

Last failure was Flame Sense lost during run.

Maximum recycle count exceeded

Combustion air blower is de-energized, Circulating blower is

de-energized after the "OFF" delay.

After 5-minute delay time, control system will reset and initiate a

new ignition sequence,

Ignition system control switch must be inthe ON position.

Pressure switches operation, tubing, and wiring.

Restrictions in furnace air intake or vent piping.

Main limit switch.

Manual reset burner rellout switch.

Limit and rellout switch wiring is in good condition and securely

connected.

Flame at pilot burner.

Gas supply off or pressure too low or high for appliance to operate.

Damaged or broken HIS element

Line voltage HOT leadwire not connected to L1 terminal on ST9160B.

Furnace not properly earth grounded.

Flame sense rod contaminated or in incorrect position.

Pilot burner located in incorrect position.

Pilot burner lead wires are in good condition and popery connected.

Pressure switches operation, tubing, and wiring.

Gas supply off orpressure too low orhigh for appliance to operate.

Line voltage HOT leadwire not connected to L1 terminal on ST9160B.

Furnace not properly earth grounded.

Flame sense rod contaminated or in incorrect position.

Pilot burner located in incorrect position.

Pilot burner lead wires are in good condition and properly connected.

Cycling, pressure switch

Condensate drain blocked

Pressure switches operation, tubing, and wiring.

44001 1114O0 [_