NOTE:Allgasketsandsealsmustbein place for sealed combus-

tion applications.

Ensure that the vent fitting is securely attached to the combustion

blower using the rubber coupling and clamps.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened ifan elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the cla rap.

This configuration allows left side venting from the furnace. Ifright

side venting is required, the combustion blower must be relocated

on the plastic transition box. Loosen the four(4) screws that se-

cure the blower to the transition approximately 1/2". Rotate the

blower 180 ° and secure with the four(4) screws. Note that some

combustion blowers have plastic spacers on the mounting legs of

the blower located at the 6 and 12 o'clock positions (blower snout

to the left or right) that are required for proper fit up of the blower to

the transition. Use caution to not over tighten the screws to pre-

vent stripping out of the plastic mounting holes.

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a 5° to

10 ° downward slope.

Plug the upper drain stub on the vent fitting with the yellow plastic

cap.

Connect the PVC vent extension pipe to the vent fitting. This pipe

has a built-in channel to assist vent condensate disposal.

Align the arrow on the PVC pipe with the airflow marking arrow on

the vent fitting. See label on the PVC pipe for proper installation.

This pipe may only be shortened if an elbow is used to connect the

PVC vent extension tube to field-installed vent pipe. Securely at-

tach the PVC vent extension pipe to the vent fitting with the cla rap.

Remove the pressure switch hose from the upper stub on the

plastic transition box.

Relocate the plastic caps on the stubs of the plastic transition box

from the lower stubs to the upper stubs and secure tightly with the

clamps.

Route the pressure switch hose to the lower stub on the plastic

transition box. Cut off excess hose and discard. Connect the pres-

sure switch hose to the lower stub on the plastic transition box.

NOTE: Failure to correctly install the pressure switch hose to the

transition box can adversely affect the safety control operation.

Connect the 3/4" OD rubber hose with the 90 ° bend to the drain

stub on the bottom of the plastic transition box and secure with a

3/4" clamp.

Route the hose to the large drain stub on the condensate trap. Cut

off excess hose and discard. Connect the hose to the drain stub

on the transition and secure with a 3/4" clamp.

Connect the 5/8" OD rubber hose with the 90 ° bend to the left

drain stub on the vent fitting and secure with a 5/8" clamp.

Route the hose to the smaller stub on the condensate trap. Cut off

excess hose and discard. Connect the hose to the drain stub on

the trap and secure with a 5/8" clamp.

For left side or right side mounted condensate trap, the pres-

sure tap on the condensate trap MUST be connected to the un-

used pressure tap located on the top of the plastic transition box.

Remove the plastic caps from the pressure tap on the condensate

trap and the plastic transition and connect the 5/16" OD rubber

hose. (See Figure 17)

NOTE: Route hoses to the condensate trap with no kinking or

binding for proper condensate drainage.

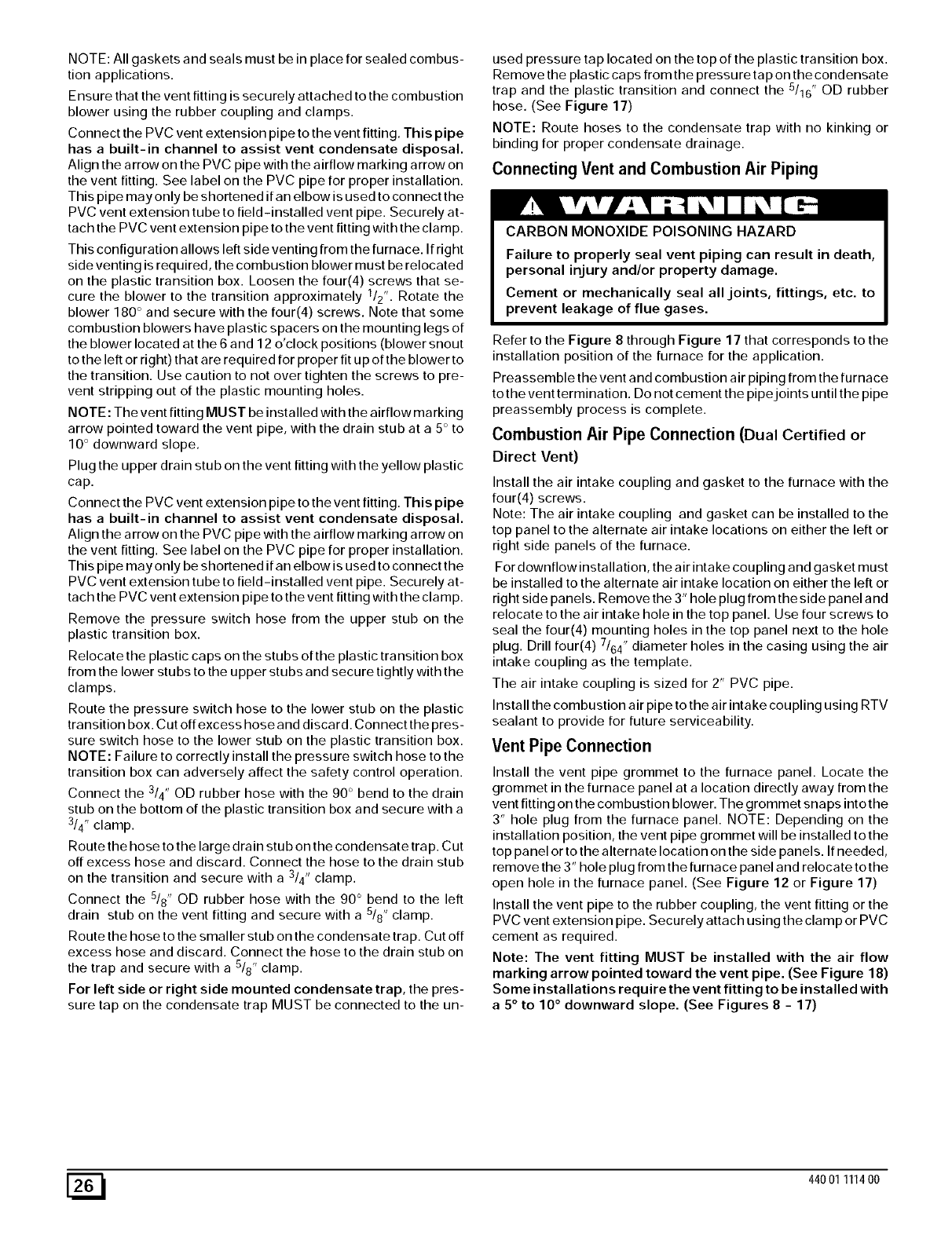

Connecting Vent and Combustion Air Piping

CARBON MONOXIDE POISONING HAZARD

Failure to properly seal vent piping can result in death,

personal injury and/or property damage.

Cement or mechanically seal all joints, fittings, etc. to

prevent leakage of flue gases.

Refer to the Figure 8 through Figure 17 that corresponds to the

installation position of the furnace for the application.

Preassemble the vent and combustion air piping from the furnace

to the vent termination. Do not cement the pipe joints until the pipe

preassembly process is complete.

Combustion Air Pipe Connection (Dual Certified or

Direct Vent)

Install the air intake coupling and gasket to the furnace with the

four(4) screws.

Note: The air intake coupling and gasket can be installed to the

top panel to the alternate air intake locations on either the left or

right side panels of the furnace.

For downflowinstallation, the air intake coupling and gasket must

be installed to the alternate air intake location on either the left or

right side panels. Remove the 3" hole plug from the side panel and

relocate to the air intake hole in the top panel. Use four screws to

seal the four(4) mounting holes in the top panel next to the hole

plug. Drill four(4) 7/64" diameter holes in the casing using the air

intake coupling as the template.

The air intake coupling is sized for 2" PVC pipe.

Install the combustion air pipe to the air intake coupling using RTV

sealant to provide for future serviceability.

Vent Pipe Connection

Install the vent pipe grommet to the furnace panel. Locate the

grommet in the furnace panel at a location directly away from the

vent fitting on the combustion blower. The grommet snaps intothe

3" hole plug from the furnace panel. NOTE: Depending on the

installation position, the vent pipe grommet will be installed to the

top panel or tothe alternate location on the side panels. Ifneeded,

remove the 3" hole plug from the furnace panel and relocate to the

open hole in the furnace panel. (See Figure 12 or Figure 17)

Install the vent pipe to the rubber coupling, the vent fitting or the

PVC vent extension pipe. Securely attach using the clamp or PVC

cement as required.

Note: The vent fitting MUST be installed with the air flow

marking arrow pointed toward the vent pipe. (See Figure 18)

Some installations require the vent fitting to be installed with

a 5° to 10 ° downward slope. (See Figures 8 - 17)

[_ 44001 111400