(Pump Rotor, continued)

10.Install blades, pump plate, air

filters, and filter end cover.

11.Replace fan guard and upper shell.

12.Adjust pump pressure (see page 11).

Note: If rotor is still binding, proceed

as follows:

13.Perform steps 1 thru 6 (see page 13).

14.Place fine grade sandpaper (600

grit) on flat surface. Sand rotor

lightly in "figure 8" motion four

times (see Figure 29).

15.Reinstall insert and rotor.

16.Perforln steps 10 thru 12 above.

SPECIFICATIONS

WIRING

DIAGRAMS

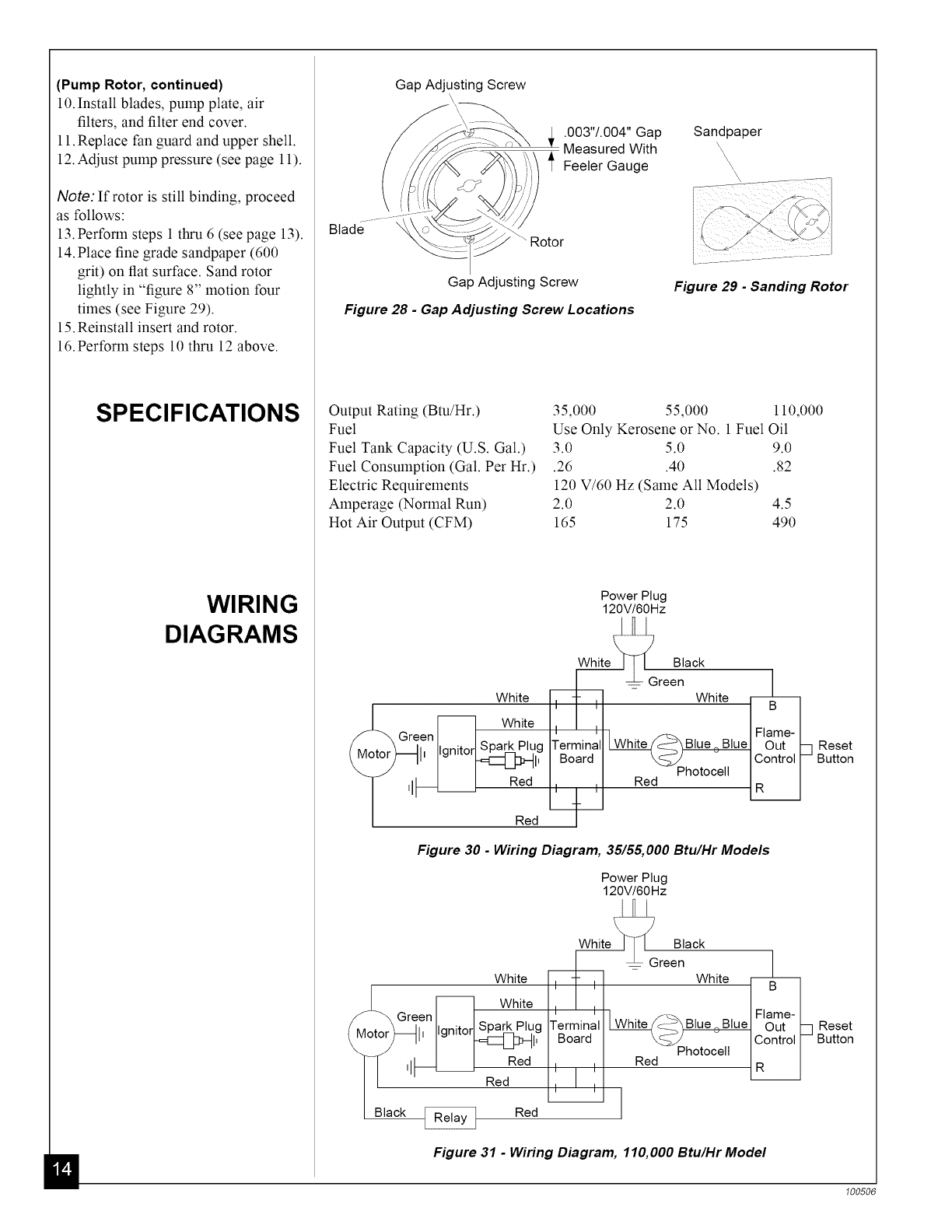

Gap Adjusting Screw

.003"/.004" Gap

Measured With

_" Feeler Gauge

Blade

Gap Adjusting Screw

Figure 28 - Gap Adjusting Screw Locations

Sandpaper

\

\\\\

\

Figure 29 - Sanding Rotor

Output Rating (Bin/Hr.)

Fuel

Fuel Tank Capacity (U.S. Gal.)

Fuel Consumption (Gal. Per Hr.)

Electric Requirements

Amperage (Normal Run)

Hot Air Output (CFM)

35,000 55,000 ll0,000

Use Only KeroseneorNo. lFuelOil

3.0 5.0 9.0

.26 .40 .82

120 V/60 Hz(Same All Models)

2.0 2.0 4.5

165 175 490

White

White

Green I I

, _ h I_÷_1 Spark Plug

_lll_¢or I_ I'

Red

Power Plug

120V/60Hz

White__ Black

_- Green

I -I II White

/

I ' II I _ I Fla

rerminall_Blue°BlUelCoCBoardl

Photocell

/

I , II Red IR

Figure 30- Wiring Diagram, 35/55,000 Btu/Hr Models

White

White

Red

Red

Red

Power Plug

120V/60Hz

White__ Black

L Green

- White

_5 BlueoBlue

Red Photocell I_ °

)

rrle-

ut

rrle-

ut

Figure 31 - Wiring Diagram, 110,000 Btu/Hr Model

Reset

Button

Reset

Button

10050u