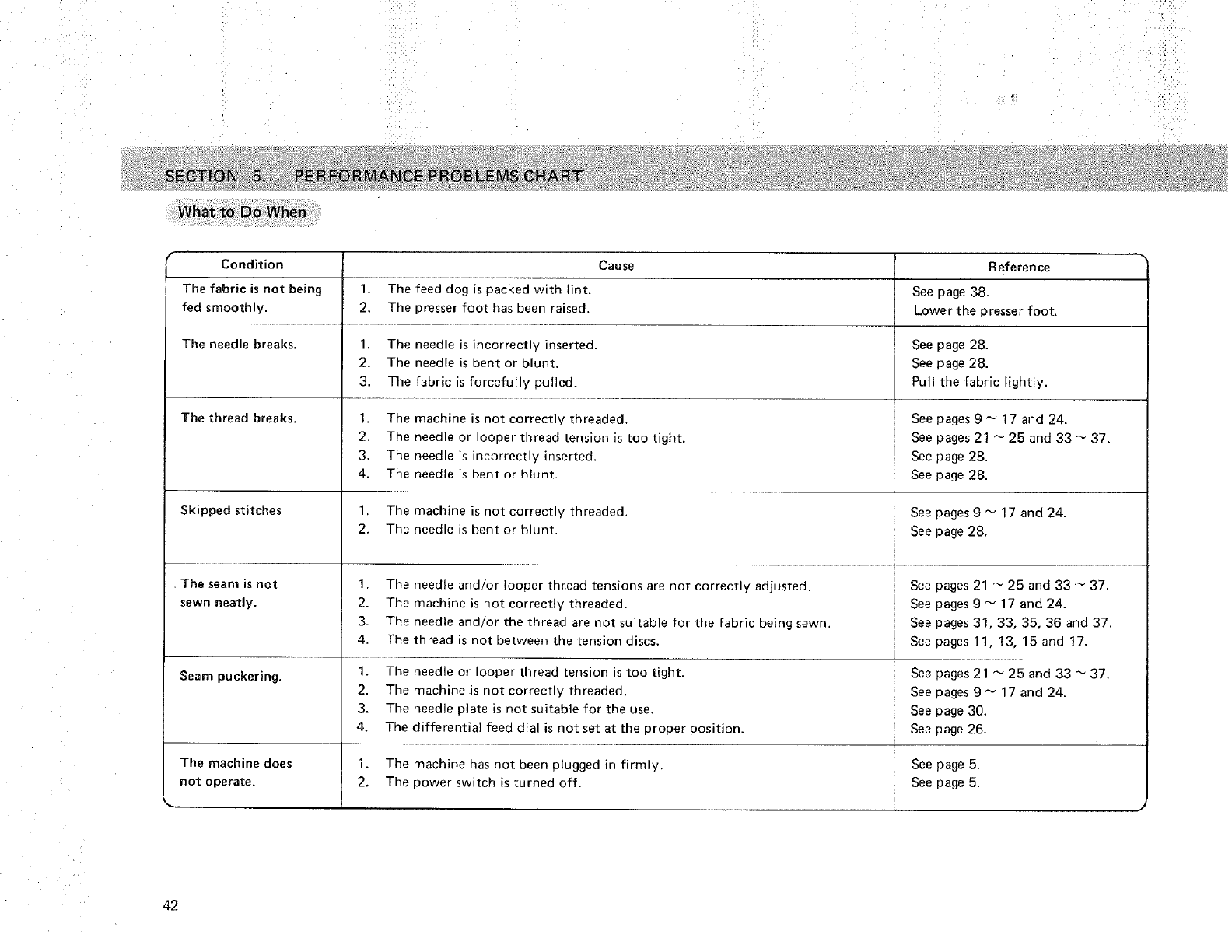

What to Do When

Condition

The fabric is not being

fed smoothly.

The needle breaks.

The thread breaks.

Skipped stitches

. The seam is not

sewn neatay.

Seam puckering.

Cause

1. The feed dog is packed with lint.

2, The presser foot has been raised.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The fabric is forcefully pulled.

1. The machine is not correctly threaded.

2. The needle or looper thread tension is too tight.

3. The needle is incorrectly inserted.

4. The needle is bent or blunt.

1. The machine is not correctly threaded.

2. The needle is bent or blunt.

1. The needle and!or looper thread tensions are not correctly adjusted.

2. The machine is not correctly threaded.

3. The needle and/or the thread are not suitable for the fabric being sewn.

4. The thread is not between the tension discs,

1. The needle or looper thread tension is too tight.

2. The machine is not correctly threaded.

3. The needle plate is not suitable for the use.

4, The differential feed dial is not set at the proper position.

Reference

See page 38.

Lower the presser foot.

See page 28.

See page 28.

Pull the fabric lightly.

See pages 9 _ 17 and 24.

See pages 21 _ 25 and 33 _ 37.

See page 28.

See page 28.

See pages g _ 17 and 24.

See page 28.

See pages 21 _ 25 and 33 _ 37.

See pages 9 _ 17 and 24.

See pages 31, 33, 35, 36 and 37.

See pages 11, 13, 15 and 17.

See pages 21 _ 25 and 33 _ 37.

See pages 9 _ 17 and 24.

See page 30.

See page 26.

The machine does 1. The machine has not been plugged in firmly. See page 5.

not operate. 2, The power switch is turned off. See page 5.

k. •

42