3

Electrical Wiring

It is imperative that adequate wire size and proper over-current protection (fuse or circuit breaker) sizes are used.

The following chart can be used as a guideline. Refer to chart on page 10 for solenoid/relay information.

12 VDC

24 VDC

32 VDC

115 VAC (1 phase)

230 VAC (1 phase)

6 to 8 ga.

8 to 10 ga.

10 to 12 ga.

12 to 14 ga.

14 to 16 ga.

3 to 4 ga.

6 to 8 ga.

8 to 10 ga.

10 to 12 ga.

12 to 14 ga.

50 amp

25 amp

20 amp

10 amp

5 amp

75 amp

40 amp

30 amp

15 amp

8 amp

PUMP VOLTAGE

PUMP MOTOR WIRE SIZE

BREAKER/FUSE SIZE

1/2 HP

3/4 HP

1/2 HP

3/4 HP

Maintenance Procedure

Procedure

Approximate Maintenance Level

MAINTENANCE

ELECTRICAL CAUTION: DISCONNECT POWER SUPPLY TO PUMP BEFORE SERVICING UNIT. FOLLOW

PROPER LOCK-OUT/TAG-OUT PROCEDURES.

Maintenance intervals and normal parts replacement vary widely depending on numerous factors such as

frequency of system use and quality of flush water, etc. The chart below is intended strictly as a general

guideline. Owner discretion and consideration of actual usage must be the first basis for determining proper

maintenance levels.

Change Oil

Inspect Diaphragm

Inspect Rod Bushing

Inspect Eccentric Pin

Duckbill Valve Replacement

Speed Reducer Replacement

Motor Replacement

A

B

C

D

E

F

G

See instructions

Every two years

Every two years

Every two years

Every two years

If needed

If needed

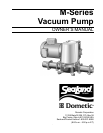

A. CHANGE OIL

The gear reducer oil should be changed after first 50 hours, thereafter

every 200 hours. Drain and fill with 90W oil or equivalent to bottom of

oil level inspection hole (opposite of output shaft). Grease the rod

bushing every 200 hours. (See item 9 on Pump Parts List)

B. DIAPHRAGM REPLACEMENT

CAUTION: KEEP HANDS AND ALL OTHER EXTREMITIES AWAY FROM ROD AND DIAPHRAGM. FLUSH

THE PUMP WITH CLEAN WATER AND DISINFECTANT BEFORE SERVICING.

When replacing a diaphragm, be sure to follow maintenance instructions B-D.

IMPORTANT: Incorrect alignments and clearances may cause pre-

mature diaphragm failure. It is important to insure that proper

alignment is achieved between the eccentric pin and the dia-

phragm rod. Make sure that clearances are correct between the

diaphragm rod and the eccentric (Fig. 6) and also between the

eccentric and the gear reducer hub (Fig. 7).

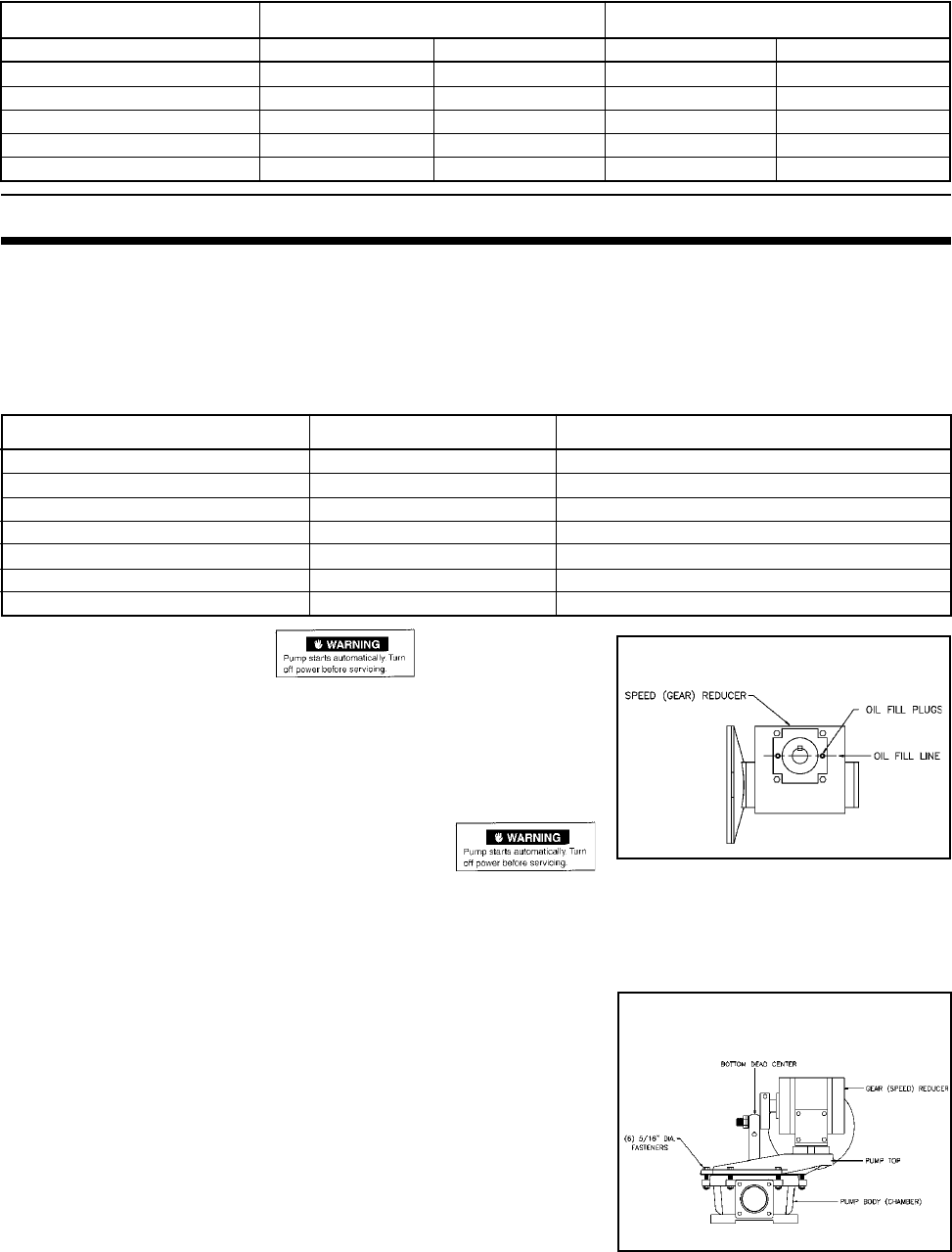

To Remove the Diaphragm:

1. Remove pump cover (not used in SaniService applications).

2. Jog motor until rod is at bottom dead center position.

NOTE: See manual rotation method on page 4.

3. Close the maintenance valves (if installed) in the inlet and outlet

piping.

Fig. 2

Fig. 1